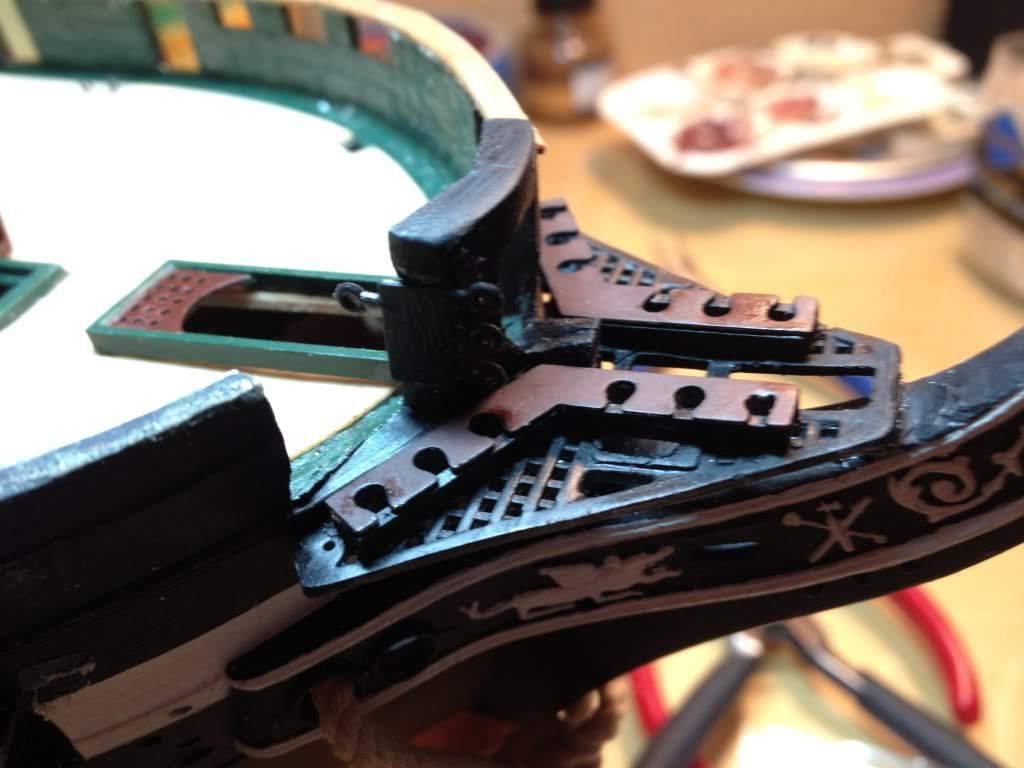

Arnie’s diagram is for a fiddle block, which uses non-coaxial sheaves. As the diagram shows, they are often of different diameters.

Which makes for complicated equations versus using a double block with coaxial sheaves of the same diameter.

Blocks are sized to fit the lines they serve. Around 9 times diameter (3x circumference) for natural fibre, and 3x diameter for wire. You size the fiddle block using the smaller sheave for this reason.

Some tackles have names, too. A Gun tackle uses two single blocks, the bitter end of the line to the becket of one block, then through the other block and back again–this can be either a two-part of three-part tackle.

A Luff tackle uses a double block and a single block; the bitter end to the becket on the single block, then through the two blocks to make either a 4-part or 5-part hoist.

Moving to one double and one triple block gives a Gyn tackle, a 5 or 6 part hoist.

The recoil tackle on the main guns is set up as 4-part luff tackle, if memory serves. One reason to use gun tackle instead of other tackle is in speed. The more sheaves in a tackle, the more line to reeve it. Every added sheave makes for an easier pull, but it’s also proportionately more line to pull.

Let’s say a gun tackle needed a “pull” of 6’ of line to move the blocks three feet. Changing to luff tackle adds more than six feet of line in the three foot “throw” of the tackle. So, instead of pulling 6’ of line, you need to pull 13-14’ of line. This is not as fast, and leaves a lot more line on the deck–neither of which are ideal for a fighting ship.

Yeah. math–you can grow up all you want to, but, you still wind up using it every day.