The old yellow box MS kits seem to be going for good prices right now on eBay.

I just added this kit to my retirement package.

The old yellow box MS kits seem to be going for good prices right now on eBay.

I just added this kit to my retirement package.

It’s a nice, though very old, kit; I hope yours doesn’t have lead fittings. Maybe it’s a good idea to know just what it is. It’s based on a set of lines in a book by a draftsman named Merestier, who made a study of American ships in the early nineteenth century. The drawing doesn’t have a name on it; it represents a generic Baltimore clipper schooner of the sort that might well have served as an American privateer in the War of 1812. The source of the name “Dapper Tom” was a well-guarded secret for many years, but Model Expo eventually let the cat out of the bag: “Dapper Tom” was the college nickname of John Shedd, one of the two founders of the original Model Shipways.

Love those old MS kits. Couple of people cleaning out stashes gave me old kits, 'cause they know I will tackle something like that. Haven’t started either yet, but will. Also have found at antique shops and rummage sales a couple of old Sterling ship kits, the solid hull variety, not their built-up ones (though I have one of those from my youth).

Ayuh. I’ve got a bunch of MS and Marine Models kits in the stash. Probably never will build them, but am happy to have them. In fact, I have an example of the kit that got me into wooden ship modeling - the Lion’s Whelp, a bomb ketch by Marine Models. In the mid 1950s, my Dad was communications officer for the Panama Canal Zone and one of my family’s good friends was a Catholic chaplain who built ship models. I used to spend time watching him build and was intrigued by the bomb ketch for some reason. Decades later, a friend of mine gave me one from his stash and I’ve had it tucked away ever since. It’s a relatively crude model by today’s standards, but still cool. [H]

Al Ross

Folks, I do believe what we have here is a documented case of CORPORATE TREASON! A senior emplyee of Bluejacket is hoarding products of the competition!

OK, Al, what’s it worth to you if we all promise not to tell Nic? (Or is he doing the same thing?)

Seriously, I can remember visiting Bluejacket at its old home in Norwalk, Connecticut, and spending a couple of interesting hours with the then-owner, John Montgomery. I mentioned, with slight embarrassment, that I was thinking about stopping by Model Shipways (Ft. Lee, New Jersey), but I didn’t know just how to find it. He gave me precise directions, and said “say hi to John and Sam for me.” And Sam Milone, at Model Shipways, told me that MS did the castings for the Sterling sailing ships, which Sam and John didn’t consider serious competition. The wood ship model business was a small, friendly one back then. I have the impression that it still is - if the HECEPOB companies are left out of the equation.

As a small business owner, it’s a measure of your success to have high quality competition.

I got a chuckle out of that too. In a world where Harley Davidsons are made in Brazil and Hondas are built in Alabama, it’s nice to see local business.

John,

You almost always have a diss against the HECEPOB companies [:D[ ! Okay, I suppose that they have earned it. Anyway, I wish that the American companies would expand their lines and have a few kits of European ships just to show the HECEPOBs how it should be done!

Bill

Well…I did get a query from the Italian police, who wondered if I knew anything about the fire at the Mamoli factory…

Bill makes a good point. I can only think of one wood European ship model kit made by an American company: the Model Shipways Mayflower. On the basis of the instruction book (which is accessible on the Model Expo website), it looks like a beauty.

Actually, I’ve never been a BlueJacket employee. I’ve worked with them for over twenty years, but as an independent contractor. Been through at least three administrations! I used to design technical training for nuclear power and taught technical writing at a college here in Maine. This is a lot more fun!! BTW, Nic builds and flies RC aircraft, too.

Al Ross

Well this is a treat. Something truly special.

I received the model this week, and thanks to the seller if you are reading this for a nice kit, a fair description and fedex overnight.

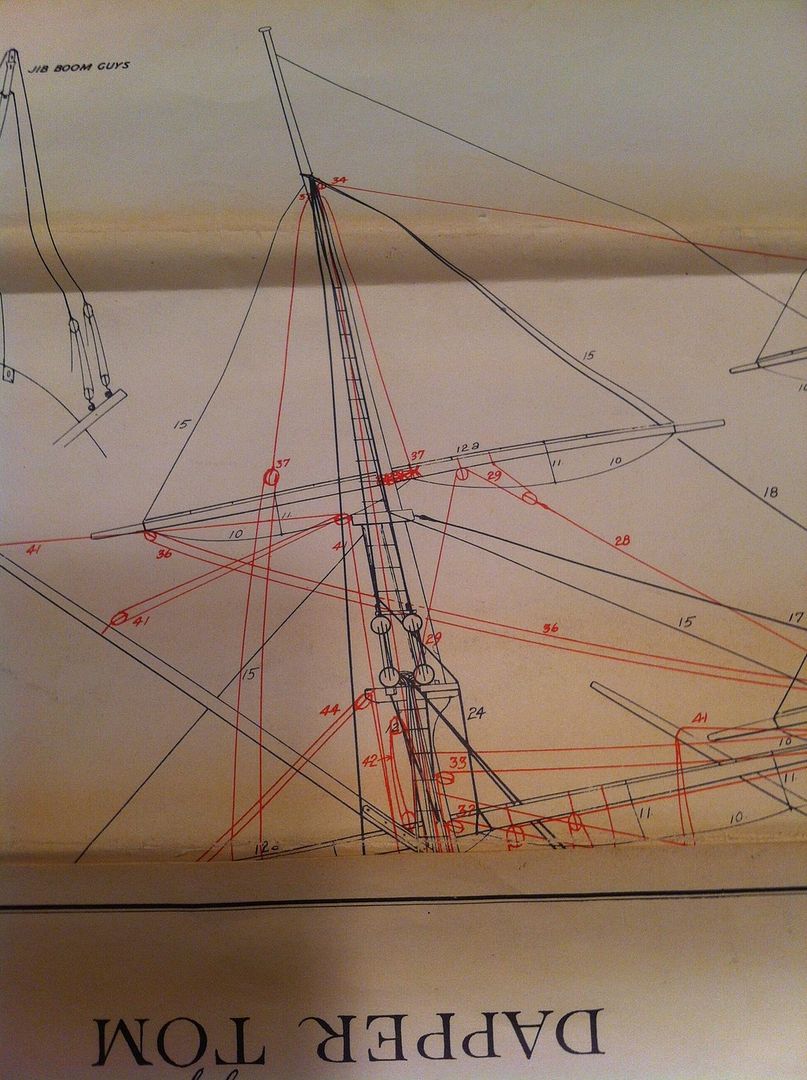

The model has been started, as far as cutting out and shaping the parts for the keel. In order to make the patterns, the modeler cut out the drawing parts, but saved them. I’ve taped the drawing back together, and I’m happy with that. The drawings are signed “L Da Vinci” in the lower left corner, and J.R.S. in the title block. I assume that would be John Shedd. Very nicely drawn. When I can, I am going to bring home a drawing flat file from my office to collect all of the nice drawings I’ve bought over the years. Everything we draw now sits on a server “in the cloud”.

The modelers tools were in the box as well. I really think thats pretty nice, something worth saving. There’s some progress started on thinning the bulwarks, and it was done well. I think that was the stopping point.

A look at all of the castings shows no oxidation or flaws; they are bright and clean. They are in a nice little home built wooden box, along with all of their fittings in wax paper envelopes, and line.

The boats seem to be made out of celluloid (?), a little rough but just need TLC.

What a fun exercise in nostalgia. Yeah, JRS was John Shedd. He drew the plans for several Model Shipways kits, back when the firm was getting started (in the late 1940s).

The original owner gave you a good head start by starting to thin the bulwarks. That’s widely regarded as the nastiest part of building a solid hull kit. One relatively easy way to tackle it is with a couple of U-shaped gouges. (I’ve got a small set of carving tools from Ramelson: http://www.woodcraft.com/search2/search.aspx?query=Ramelson . Not too expensive, and they’re made out of decent steel.) Make a series of vertical cuts with the gouge, and then eventually use a chisel to take of the bumps between cuts.

I think those little boats were made by the original owner. (Or maybe he bought them at a hobby shop.) In those days Model Shipways didn’t make anything out of plastic.

You’re lucky the lead fittings are in good shape. To be safe, be sure to give them a good coat of metal primer (Tamiya, Floquil, or Rustoleum). And for heaven’s sake don’t put the finished model in an air-tight case, and don’t display it where the sun can hit it. One reason those fittings have lasted so long is that they’ve been kept in the dark.

Bill,

I hope that when you get around to building this beauty, that you will do a WIP. I would love to see a wooden ship log here and I am sure there are a large number of fellow forum members who would agree.

Steve

The lines of the hul sure resemble the Model Shipways Phantom pilot boat that I built years ago.While the solid hull kits have their charms,I am into big plank on bulkhead ships.My Admiral Vernon is coming along nicely and should look great in the living room when completed.

I would be planking both the inside and outside faces of the bulwarks. Adding stanchions along the inside.

That would suggest the thinned down part needs to be, well, thinned down a lot.

Has anyone ever just cut them off and replaced with a built up structure? My concern would be preserving the lines.

EDIT: Bad idea. But I did find some practicums, that address the issue.

I just ordered “The Neophyte Shipmodeller’s Jackstay”.

Speaking of jackstays, the Dapper Tom has them.

Jackstays in the War of 1812 are barely possible, but highly unlikely. And it’s really tough to make them look right on that small scale. I’ leave them off.

If you try to plank both sides of the bulwarks and add stanchions you’re asking for trouble. The railing on top will have to cover four layers of wood (outside plank, precarved bulwark, inside planking, stanchion).

On my fishing schooner I found out that the practical limit for trimming the bulwarks is about 1/32". (That’s with a basswood hull; pine would be worse.) I planked the outsides and added the stanchions inside. I thought about scribing “planks” on the insides, but that really would have been noticeable.

Planking a solid hull is tougher than it looks. Bluejacket sells .020" strips in widths down to 3/64" that would help. And if the bottom is competed (as such a ship might have been) the job gets a lot simpler.

The Campbell book is an old classic. Learn everything in it and you’ll be well on the way to a thorough knowledge of sailing ship technology.

True enough, I thought anything less than 1/16" would probably be a good day.

Would you rebate the outside of the hull to allow for the planking? Or just locally above the copper? [+o(]

As for the jackstays, again probably not worth the trouble, but…

Looking at these drawings, it’s hard to understand for those now using computers, that those slack and curved lines are hard to do. They are not “freehand”.

In my apprenticeship at Skidmore, Owings and Merrill; there was an older gent who had in fact been a true apprentice of the master FLW. He had a niche drawing landscape plans, which was about the only place that SOM ever used a curve.

He had a big wooden box full of every kind of parabolic curve anyone could ever have wanted, all carefully cut natural catenaries. I used to borrow it and got into doing site plans for a while.

I may be the guy with a new toy, but… I think this little topsail schooner may be one of the prettiest things I’ve ever seen.

GM,

I wish I had known that you needed a copy of Jackstay! I have an extra copy I could have sent you.

Bill

Oh thats ok, thank you though. $ 4.95 plus $ 3.99 on Amazon.

On another subject, have you ever thought about modeling the DD560?

I got this free book about the USS Kidd from Squadron as some sort of thank you gift.

So I bought a square bridge Trumpeter Fletcher class. The you-know-who’s.

Then I got to thinking, why not the Morrison? I don’t think I am very directly related to the guy however. But it might be fun.

Yes! I have been working on that conversion for the past several months. The finished model will have a place of honor on my mantle. As for relations . . . I learned through the Clan Morrison that all Morrisons are related because, when the original Clan migrated to Northern Scotland centuries ago, it eventually branched out into two distinct branches. The last survivor of one of the branches died around 1806. The other branch has survived into today, and we all have a family connection however remote.

Bill