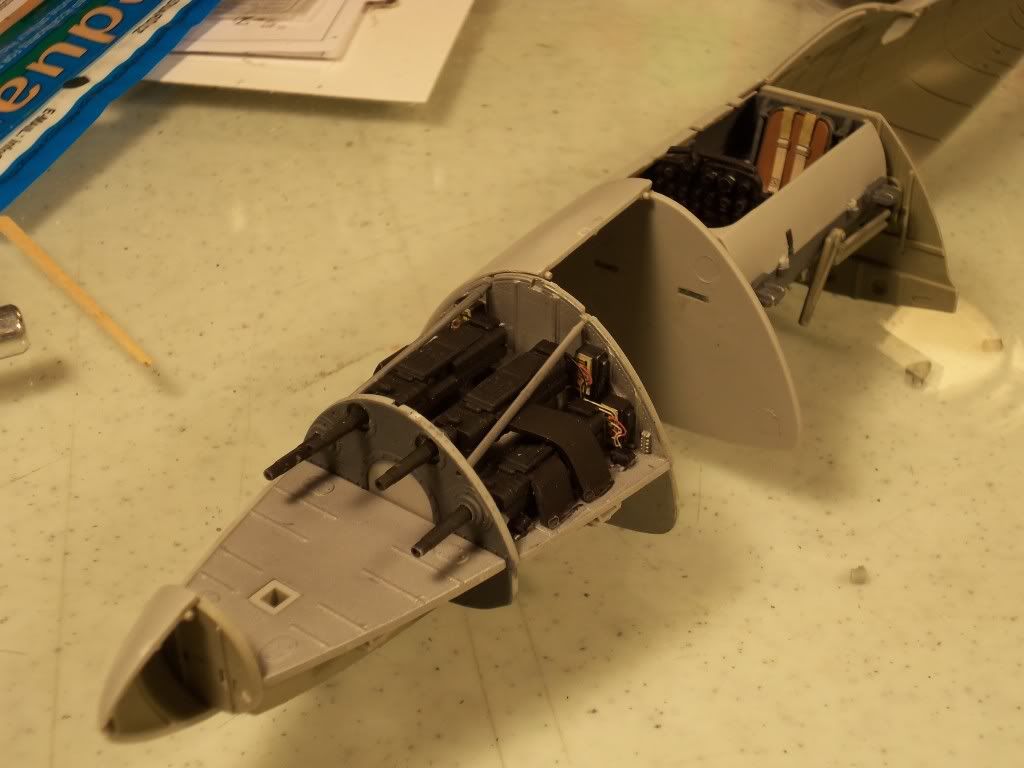

This area either side of the nose wheel bay is the ideal spot for the weight.

To get the correct weight you have to dry fit the main parts together, along with the undercart and then add weight equally both sides untill the nosewheel sits properly. Then add a little extra for luck.

I would use the metal undercart stuff for this kit and don’t even think about putting weight in the engines or around the engine nacelles. They are more or less within the same line as the main undercart and won’t do anything about tail sitting.

Hans is right. Lead shot or very small fishing weights are the best for this kind of thing. Putting money as a weight into models is not very good economy ( I’m a Yorkshireman - I know) and leaves you a few vital pennies short of that next model… do you break open the prize winning kit or…

This model needs lots of thinking about when it comes to the painting. It is best to paint lots while on the sprues. This does lead to the downside that you will have to touch up and clean parts once assembled and you may need to do lots of repainting/spraying. This is where the dry fitting comes into it.

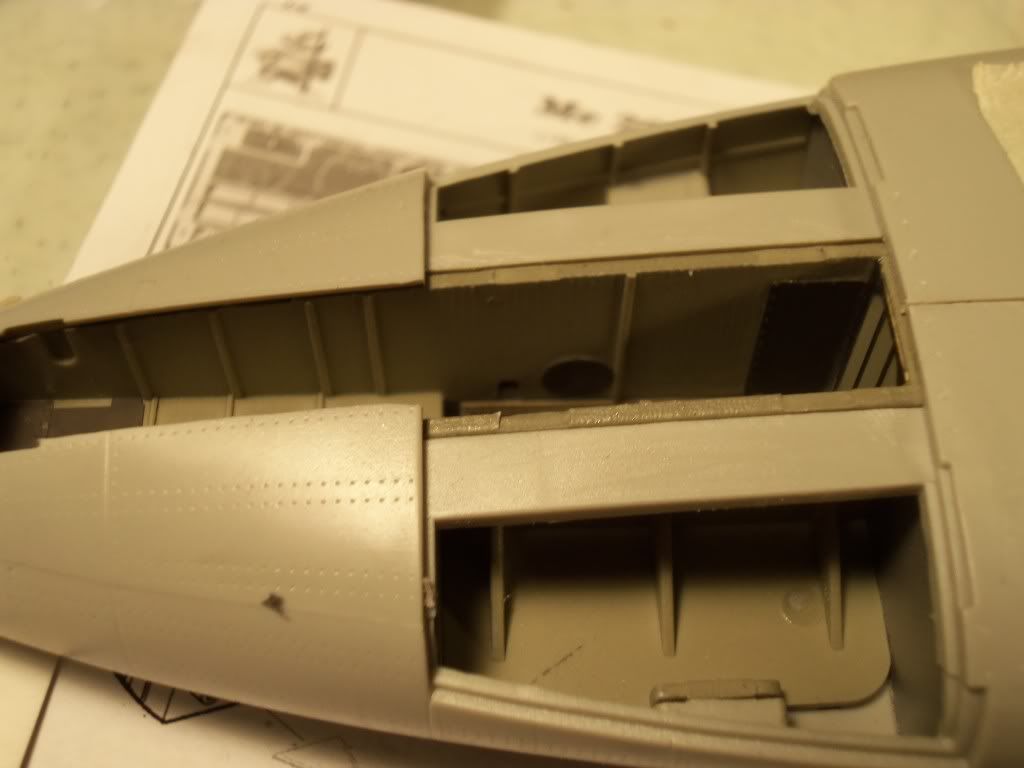

OOB with no extras this is a very good kit fit wise and there is lots of detail, with Eduards big ed set and the right colours this turns into a cabinet stopper. You may consider a mirror for it to sit on that will reflect the wheel well detail. Also the RATOGs add that little extra.

Now, the colours. Trumpeter tend not to give the correct colour codes and the colours the Luftwaffe used are always a hot debate.

Having had access to original chips and painting orders I have managed to get 100% matches from the Vallejo MOdel Colour paint range.

For the interior you will need:

Cockpit interior - RLM66 - VMC 70866 or Vallejo Model air 71055 (70866 is 100% match)

Everywhere else inside , wheelwells cockpit tub exterior etc RLM02 - VMC 70866 or model air 71044 (70886 is 100% match)

Exterior Undersurface

Either

RLM76 - VMC 70907 (100% shade match)

Or

RLM99v.1 (yes it does exist) - Not matched as yet, but FS34583 is a 100% match.

RLM99v.2 (yes it does exist) - Not matched as yet, but FS34672 is a 100% match

That should give you a starter.

James