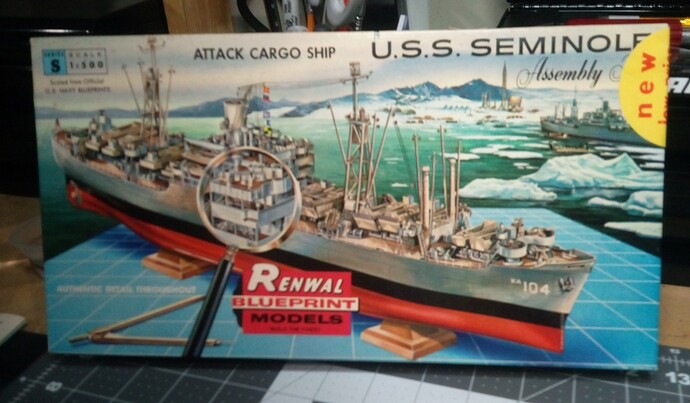

Well, it’s time for the next project. I am going to build (as I threatened in another post) a vintage Renwal USS Seminole Attack Cargo Transport. I decided to do my first build log and share with everyone here. I was inspired by Builder_2010 and his incredible work. I’m nowhere near his skill level, but what the heck!

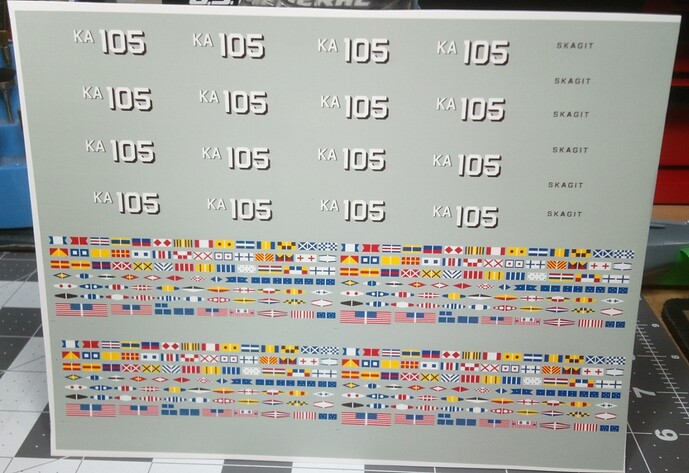

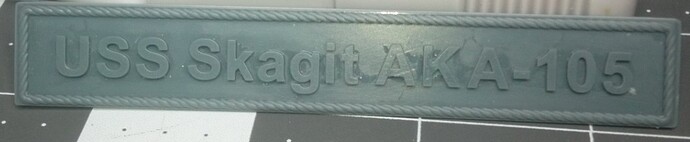

I will be rechristening the Seminole as the USS Skagit AKA-105, as a tribute to my Grandpa who served aboard her from shakedown, Europe and Pacific theatres, and was present in Tokyo Bay for the surrender. The Tolland class Attack Cargo ships were vitally import in the war and post war periods.

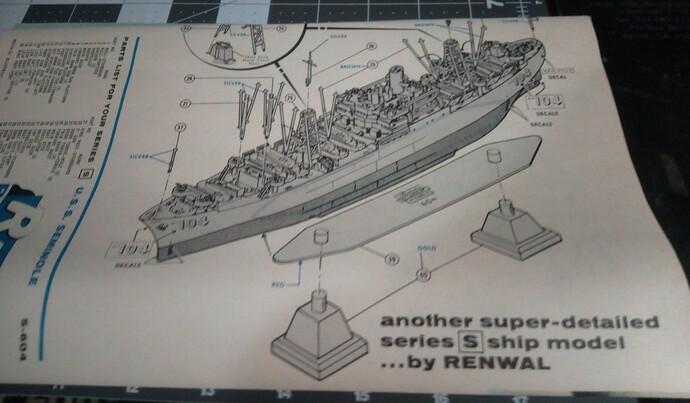

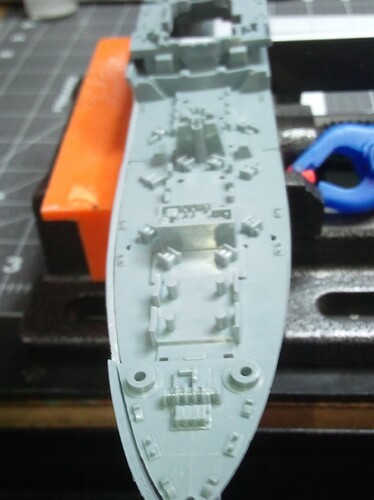

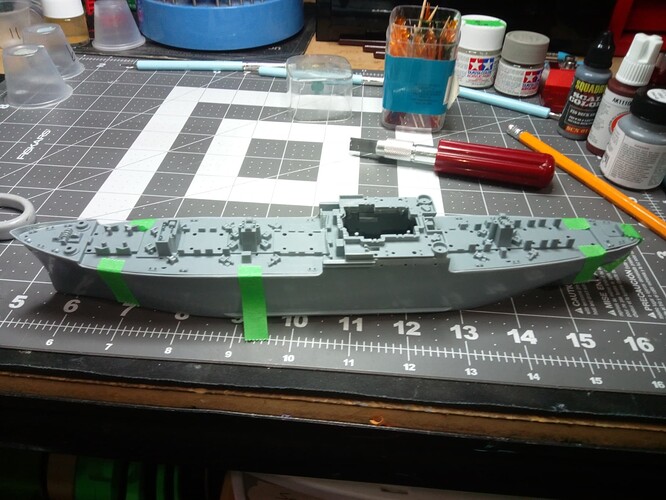

These ships are criminally overlooked by the model manufacturers in my opinion. I was fortunate to score this Vintage Renwal kit on ebay after several attempts. This was all I could find, and I’m not much of a scratch builder. I’ve heard that Atlantis Models in New York have the original molds, and there is a possibility they will be reissuing in the future, but who knows when that will be. Anyway, being made with 1950’s technology it has quirks that you would never see today, like the oddbal 1/500 scale, the 3 piece hull, the superstructure parts split horizontally in the middle, etc.

I did manage to find some 1/500 photo etched railings, ladders and stairs, which has exposed a problem immediately, but I’ll get to that in a few minutes. I had custom decals and a nameplate created so the “rebrand” will be fairly easy.

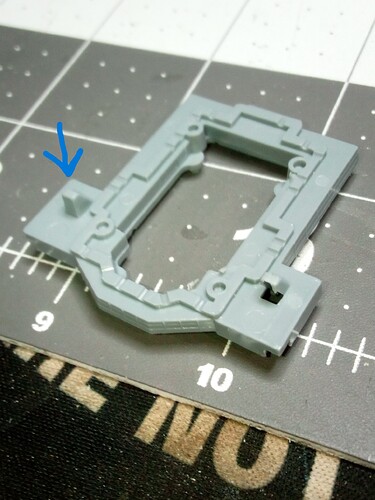

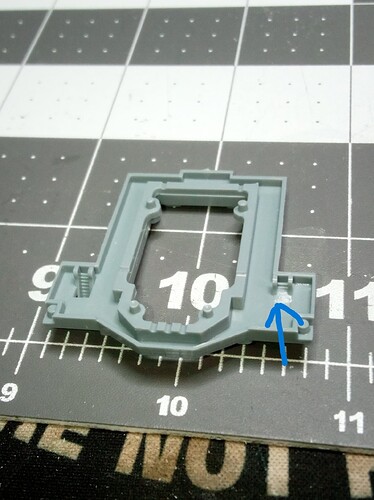

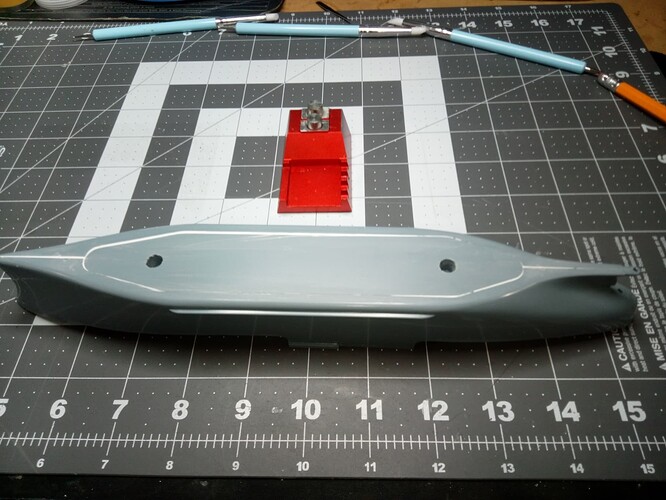

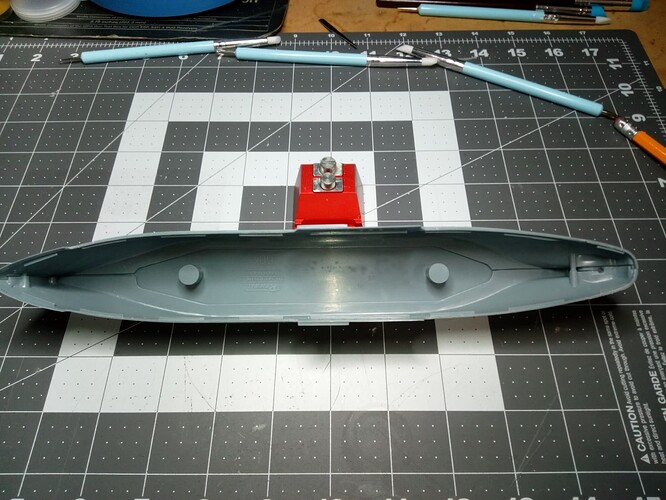

I sourced a walnut base from a trophy shop and had to figure out how to attach the pedestals to the wood without messy glue. The ships hull has two holes in the keel which the pedestals fit into. I have to use them, so I fashioned some internal “floors” out of a paint stir stick, affixed the hardware with Gorilla glue, drilled and countersunk the walnut, and voila, a functional base.

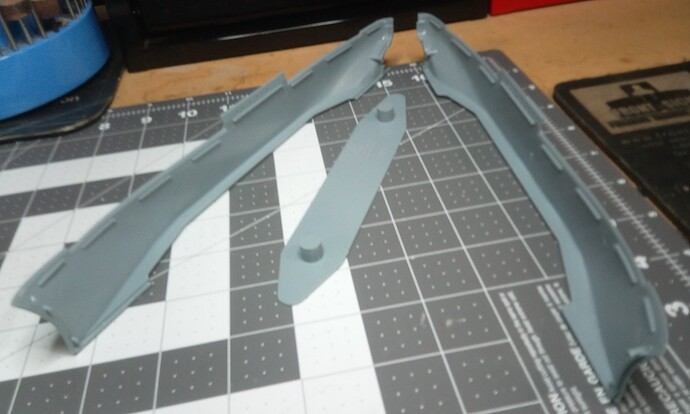

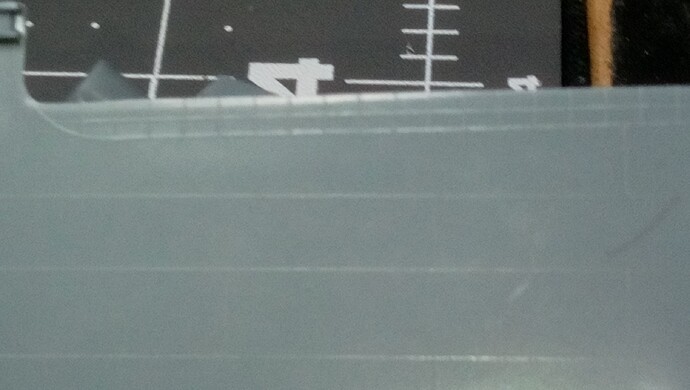

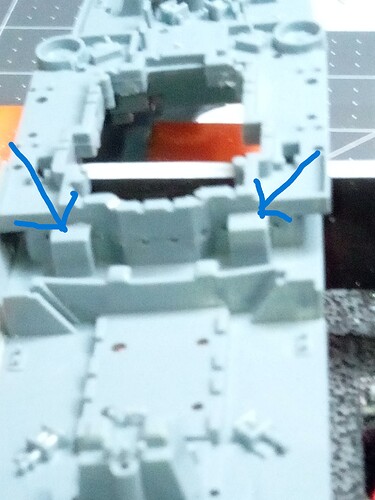

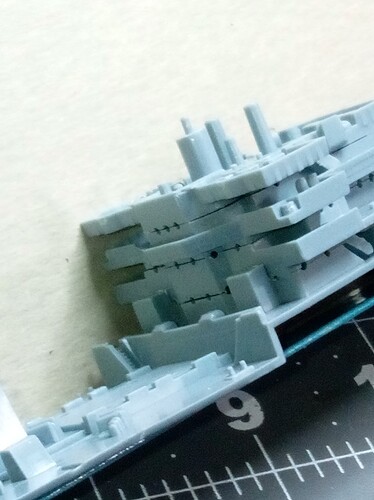

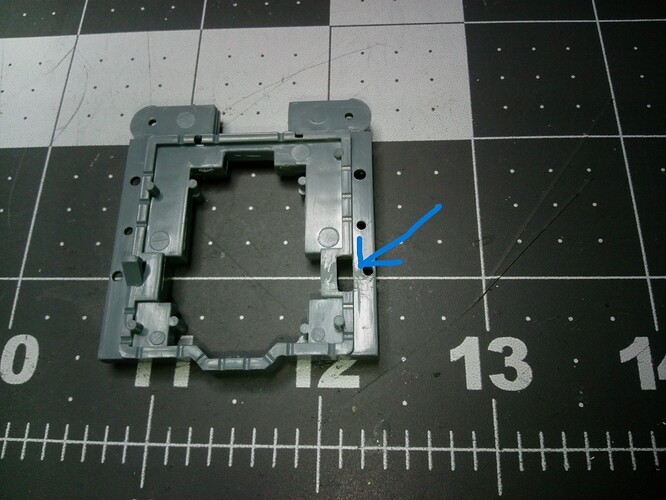

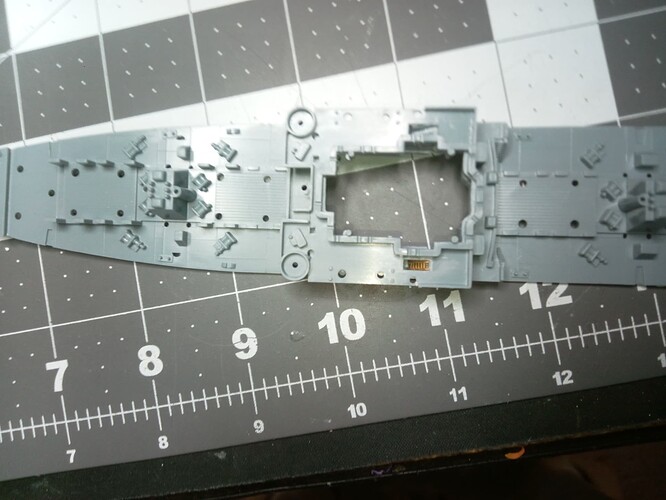

So now I need advice. My intention to use PE railings may be derailed from the jump. In the photo below, you will see that Renwal molded into the hull at the deckline, railing detail.

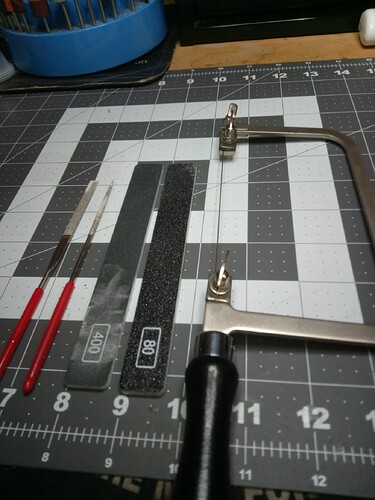

I feel that this has to be removed entirely, not just sanded off. It’s exactly the height and placement of where the pe would go. Frankly, I’m scared to cut this away and possiby damage a scarce model. Cutting may compromise the structure and deck fit. Below is additional photos of the area.

I’m open to suggestions or encouragement. I think I’ve landed on a cutting solution, but want to hear from the community before doing something stupid. Anyway, that’s it for this edition of the build log. Thanks for reading, and I hope you enjoyed it. Stay tuned, more to come!