YEEE-HAWWWW! [:P][:P][:P]

Back in the saddle again, boys, and eager to bump this one out! I’ve been thrilled at the release of the Waffetrager series lately–I’ve got four of 'em so far, I believe; the Alan one included, and the new one just released on the way as we speak. I’ve always thought these were kinda cool looking!

This one is the 12.8 cm Trumpeter version:

This is one sharp kit! The pieces almost snap together. One nice thing is this–look at how the delicate seat frames come pre-wrapped in protective foam? How COOL is that?

Here’s some of the goodies that come too–check out the sheer numbers of shells that accompany this kit! And what’s funny is that they’re NOT the 12.8 cm shells!? I’m not sure what they’re supposed to be–perhaps the shells for another version soon to be released? In any case, in case you get skeered at the mention on some merchants’ sites and the Armorama review saying that the kit has “1080 parts”, I guarantee you that they’re counting these possibly-useless shells!

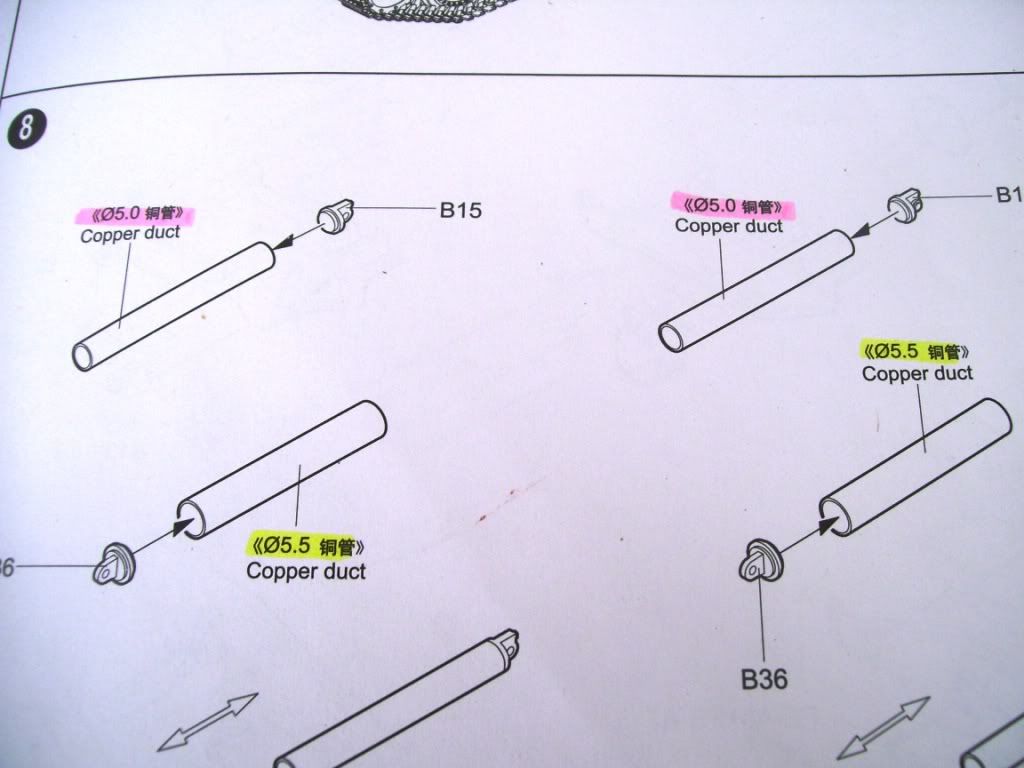

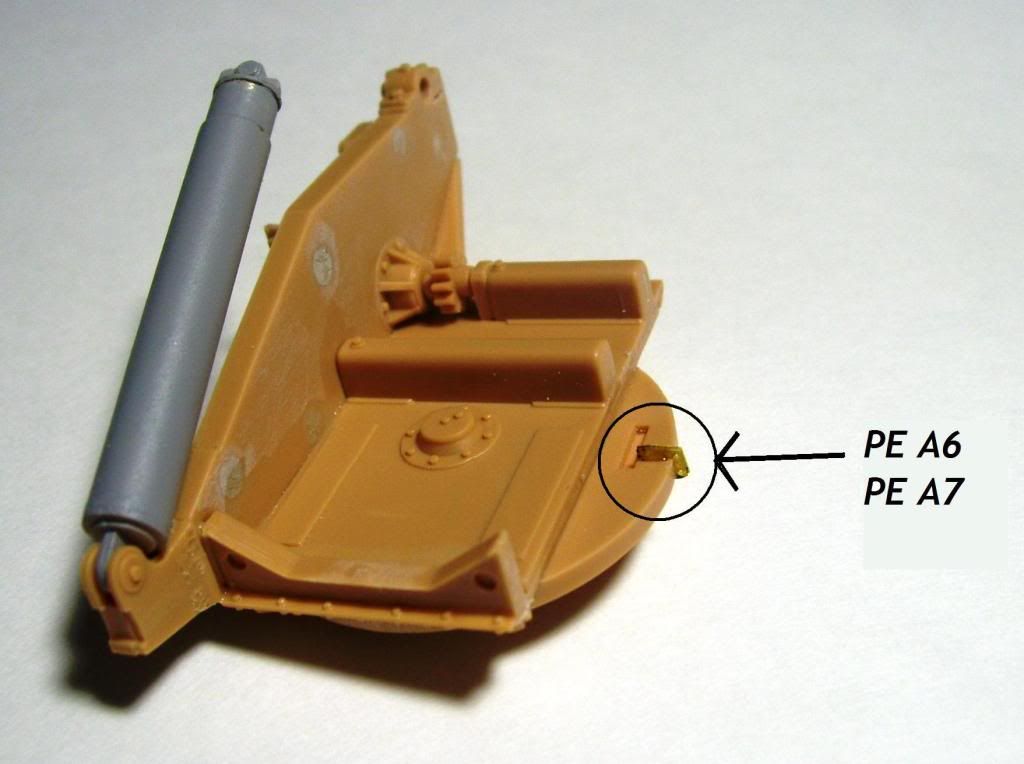

You also get some copper tubes for the recoil absorbers, and some photo etch, as well as an optional metal barrel! KEWL!

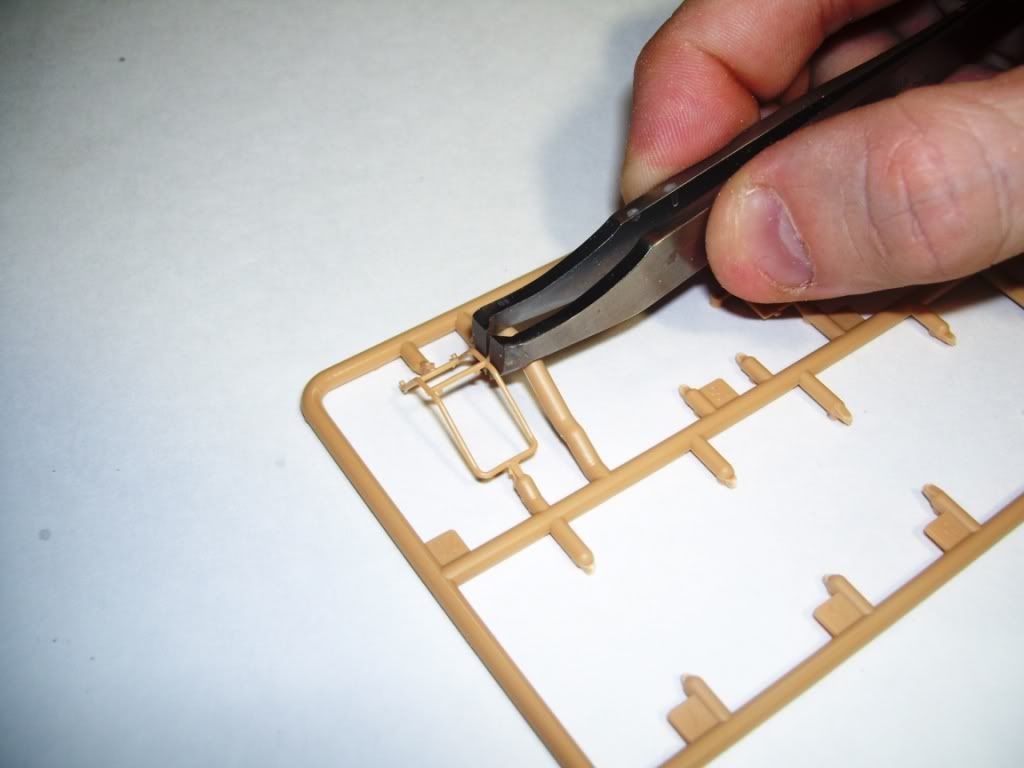

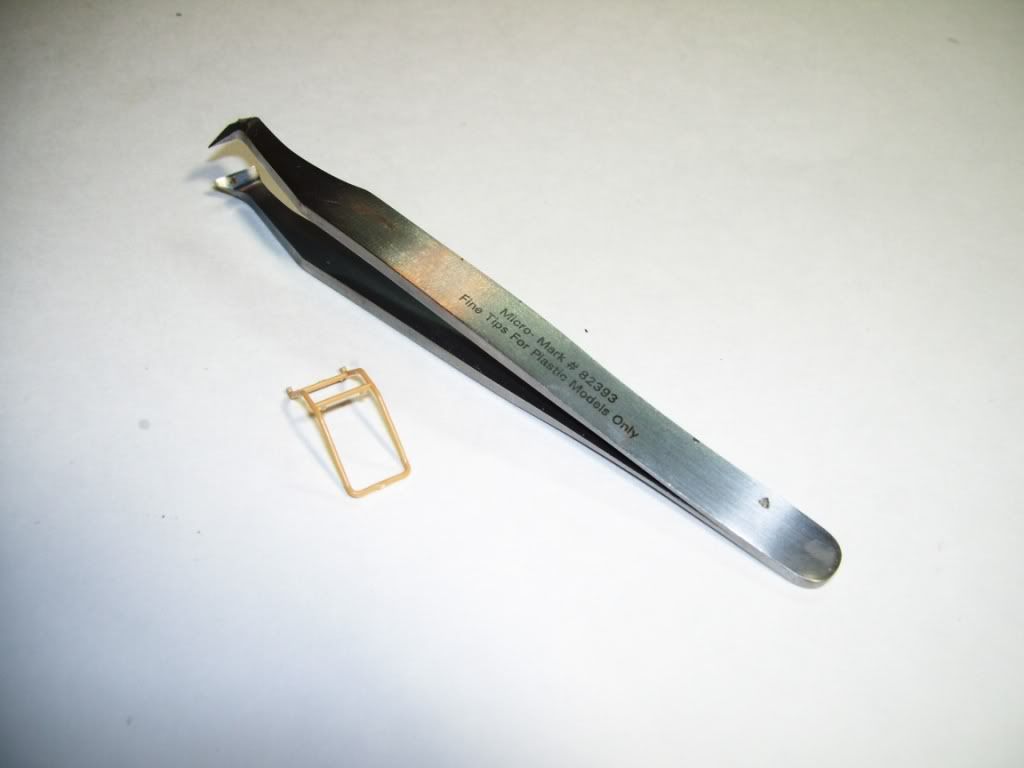

Just a heads up here–this little tool from MicroMark is the ultimate cutter for small, delicate pieces. It’s a MicroMark # 82393 Fine Tip Cutter, and it’s great for delicate pieces.

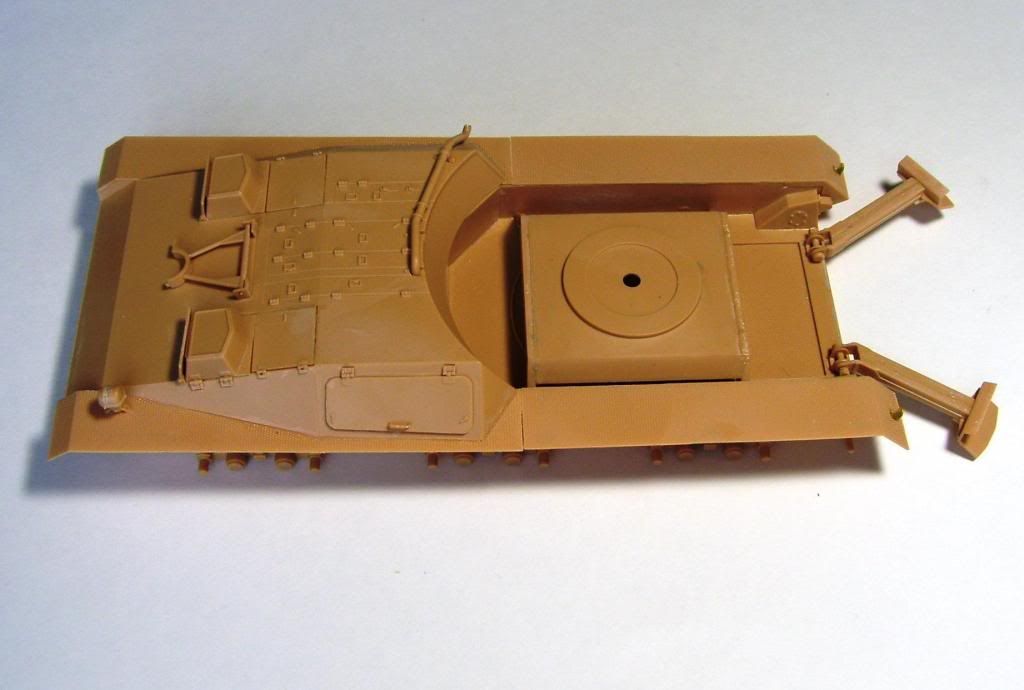

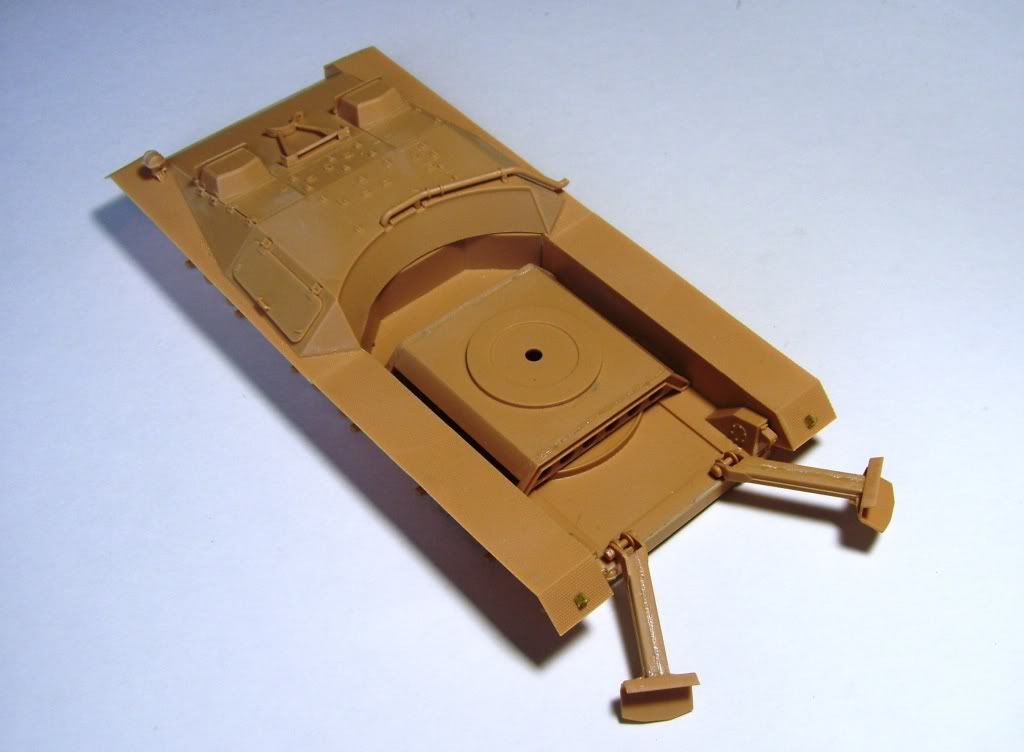

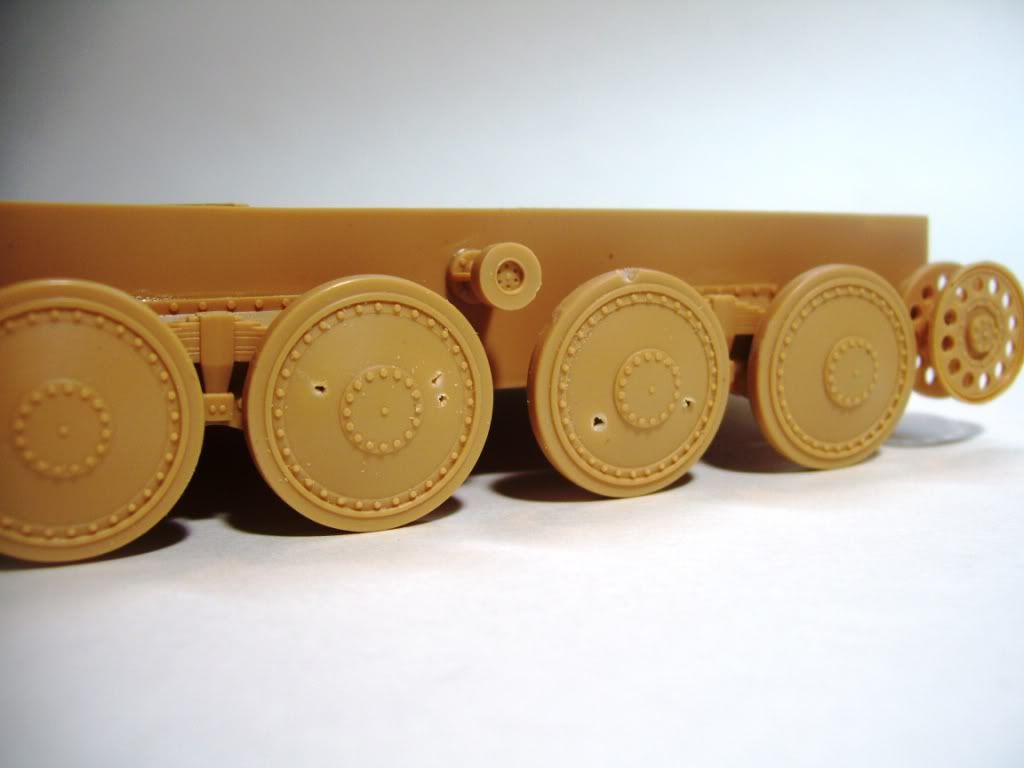

Not too much to show yet; I’ve got the hull somewhat started:

I used a Dremel tool to thin out behind two of the wheels and poked a #11 blade through them to simulate bullet damage.

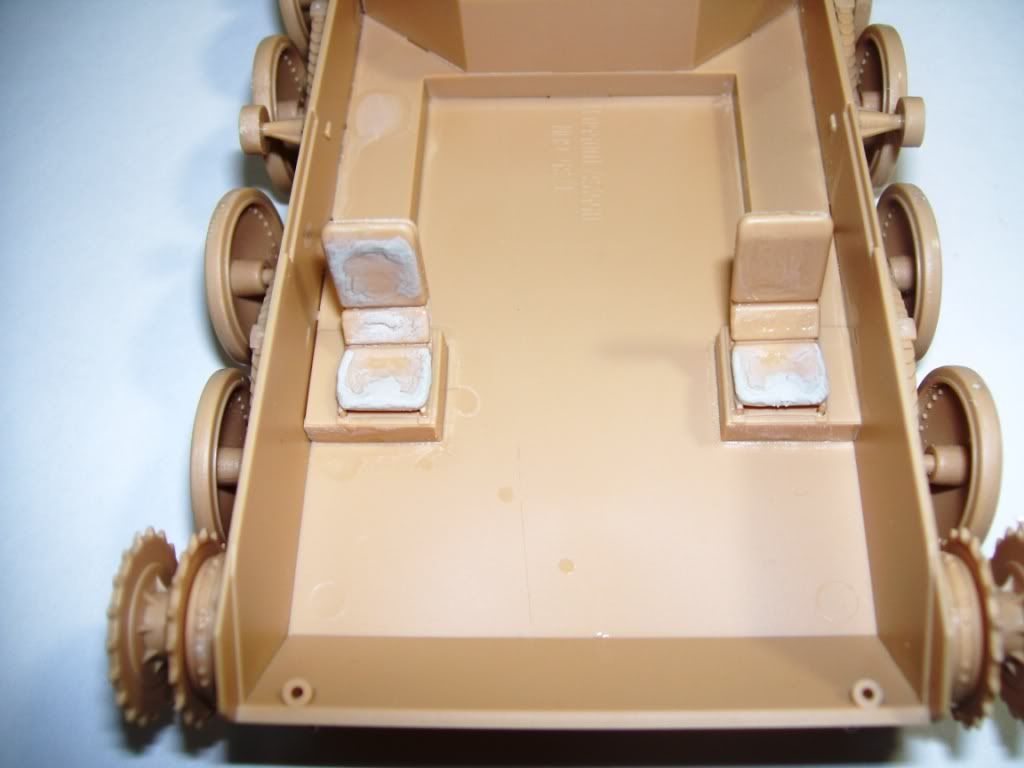

I used that same Dremel to make the seats a little “saggy”. Some putty here will help as well. I’ll sand those out a bit when they harden.

That’s it for now. I love the smell of Tenax 7 in the evenin’! Stay tuned for more! [:D]