Started this close to one year ago.

I have a much more detailed build log on Model Ship World, for anyone interested. Same handle as here. MisterMeester

There are many aspects to Trumpeter’s mold of the hull that are inaccurate. Therefore, there are quite a few corrections to do to the hull, if one cares about accuracy. Most of them, I’ve taken care of.

I do not plan on lighting the model, however I do have an aftermarket kit for the portholes “glass”. Having said that, all the portholes have been drilled out.

Most of the portholes were molded correctly, but some were missing altogether and others (about 50) are in the wrong location and require a slight repositioning. Again, for accuracy.

I added the missing portholes, but did not trust my skill set to reposition 50+ portholes and get each one EXACTLY correct, so I did not do that.

As well, some doors on the hull were incorrectly molded. Removed.

As well, parts N2 and P2 (Superstructure) had inaccuracies that I’ve corrected.

I’ve also accomplished a scratch build of shutters for the washports for the forward and aft well decks.

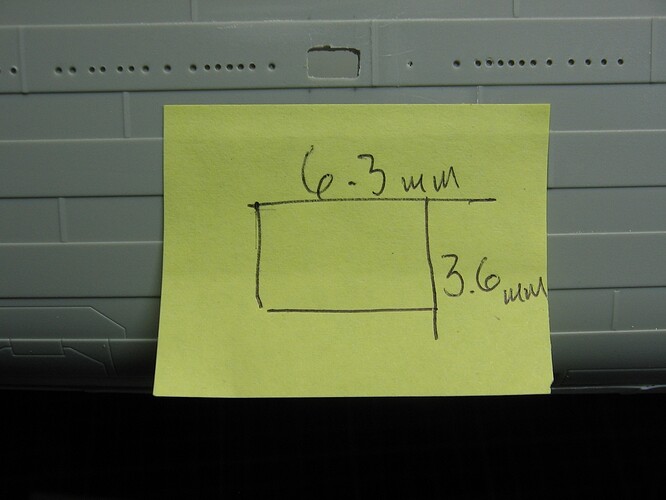

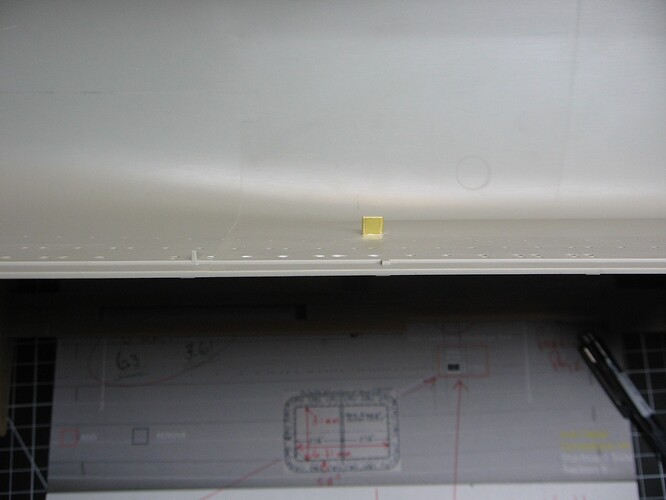

I purchased and applied an aftermarket kit for the missing stern plating. I had to do this twice. First time, I misunderstood the instructions and applied the guide template incorrectly. It turned out better though, nonetheless, as in my opinion the styrene provided in the aftermarket kit was too thick. It wasn’t to scale. So I scratch built the stern plating with thinner styrene. I used the leftover scrap styrene from the original aftermarket kit as a template, cutting each new piece from the negative spaces of that.

Also completed is an underhull plating aftermarket kit from Woody’s Model Works (aka Maritime Models) in the UK.

And this is where I’m at with it now…

The plating at the Stern Frame is scratch built. I know of no aftermarket kit that exists for that.

Lost more on the hull to do before it’ll be ready for paint. The coaling doors; condenser discharge ports; lifting pad eyes; rudder; prow hawse; bilge keels; propeller shaft housings; safety bars; a few more corrections; and dealing with rivets that have been damaged.

Hoping to get all that done by June, as I can’t paint it indoors. That has to be done outside.

Cheers,

Mark