As my first introduction to this forum, I am going to copy over a build I have in progress right now and catch you up to where I am with it right now.

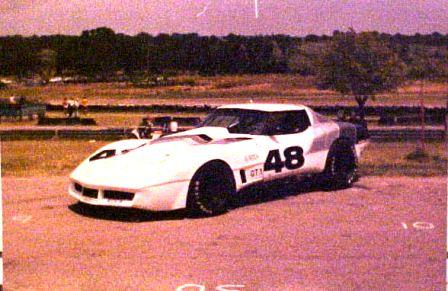

At the 1983 IMSA 3-Hour Season Finale at Daytona, my partner and I bought the 23rd finishing #46 Corvette. It was a C3-chassied/Pickett-bodied Corvette.

We took it back to our shop in Dallas, and rebuilt it from the ground up and raced it in the Sports Car Club of America amateur races in our area.

Around 1986, we were wanting to upgrade to something a little newer.

We had been in constant contact with the prior owner of the Corvette (who produced fibreglass race car bodies), and when we mentioned to him that we wanted to upgrade, he informed us that he had acquired a tube frame chassis for a 3rd Generation Camaro in order to test fit bodies to, and that he was done with it.

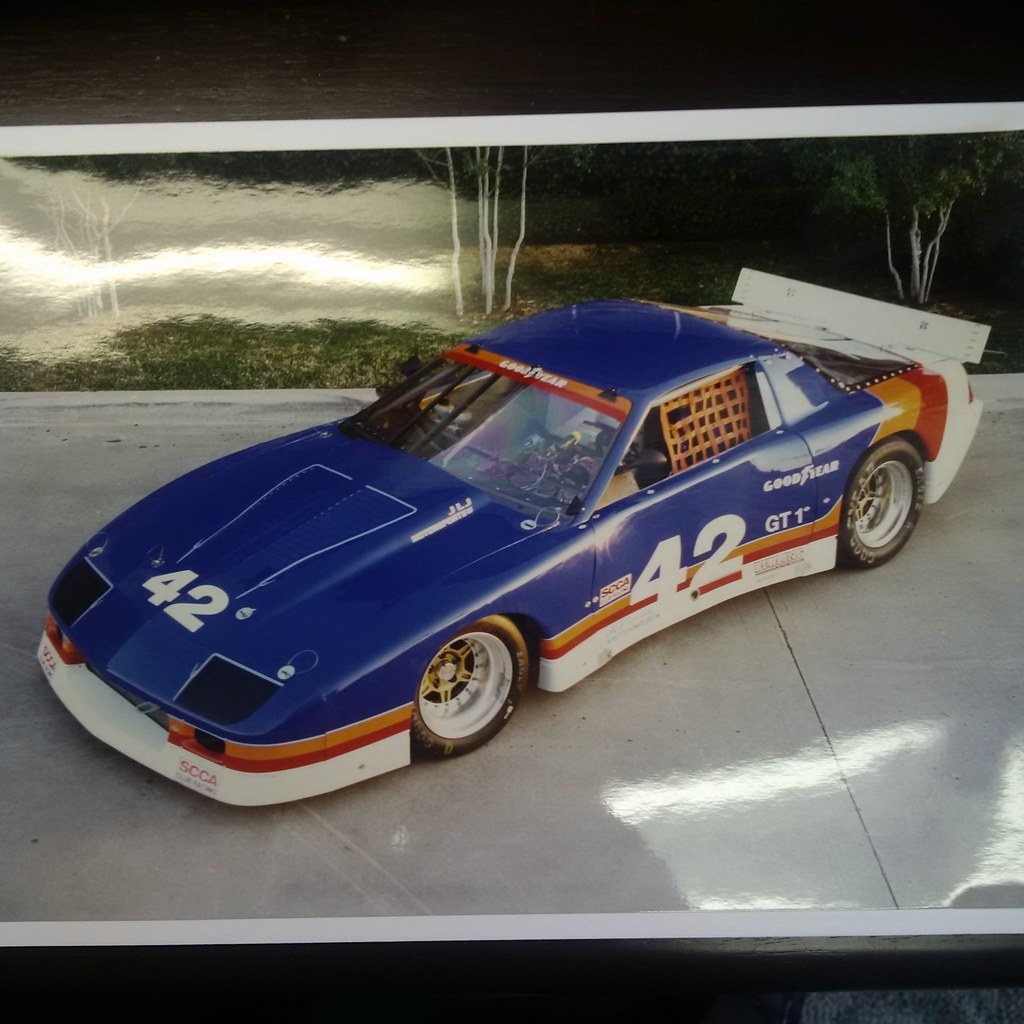

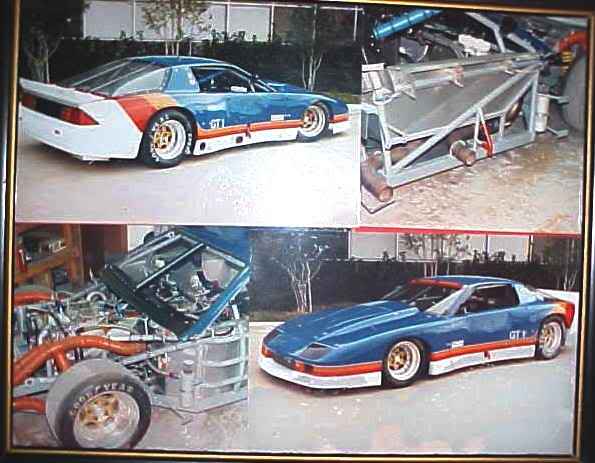

Jake and I drove to Milwaukee from Dallas, TX with the rolling chassis of our Corvette in our trailer, and drove back with, essentially, a new car in kit form. The tube frame Camaro chassis had the rollcage, and front and rear clips attached, but that was it. The rest of the car parts, suspension, rear end, fuel cell, brakes, etc. were in boxes.

Along with a couple of volunteers, and through some troubling personal and economic times, we persevered and produced our Camaro.

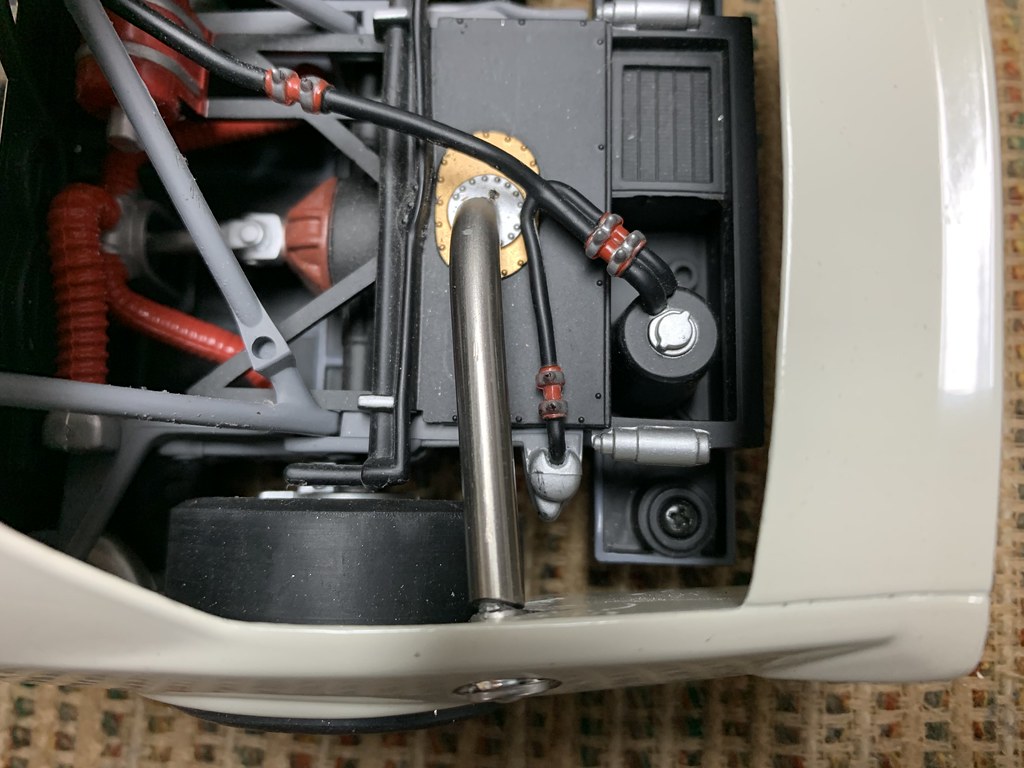

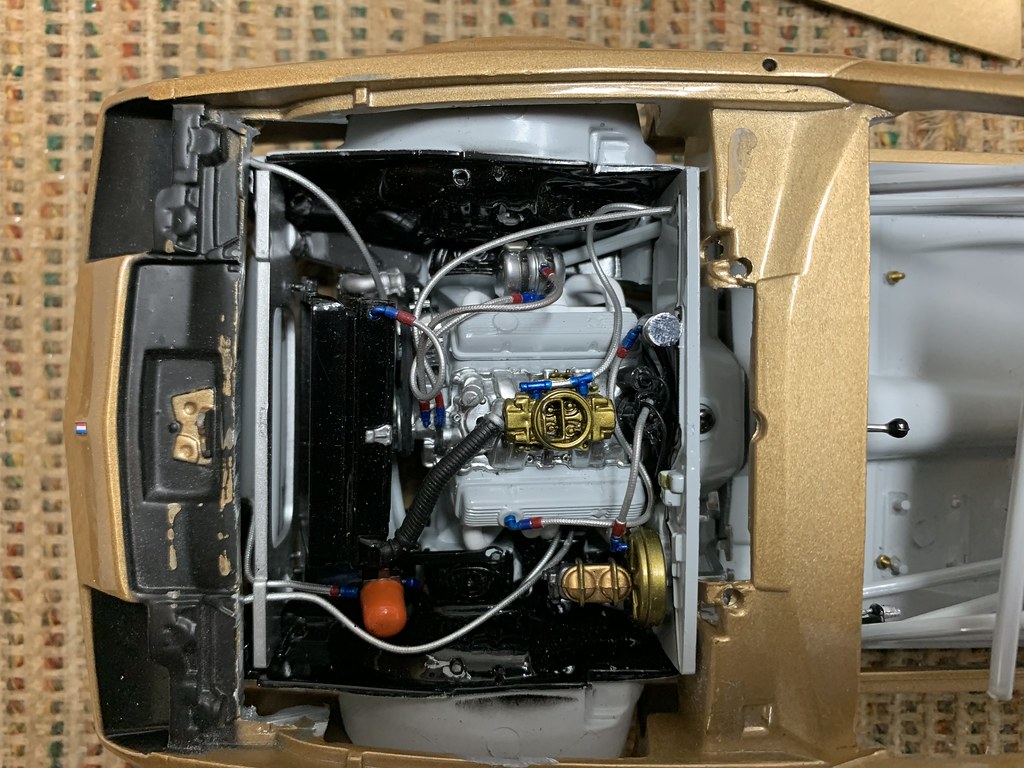

We fabricated almost everything you can see in these pictures, including hanging the body (the seller had merely mocked up his body panels with tack welded brackets and racer’s tape), completing the aluminum interior (firewall, cockpit, exhaust and driveshaft tunnel), completing all the plumbing (dry sump oil system, brakes, fuel lines, and engine cooling), completing all the wiring, and detailing and finishing.

I have been wanting to try to create a duplicate, so will be chronicling that effort here.

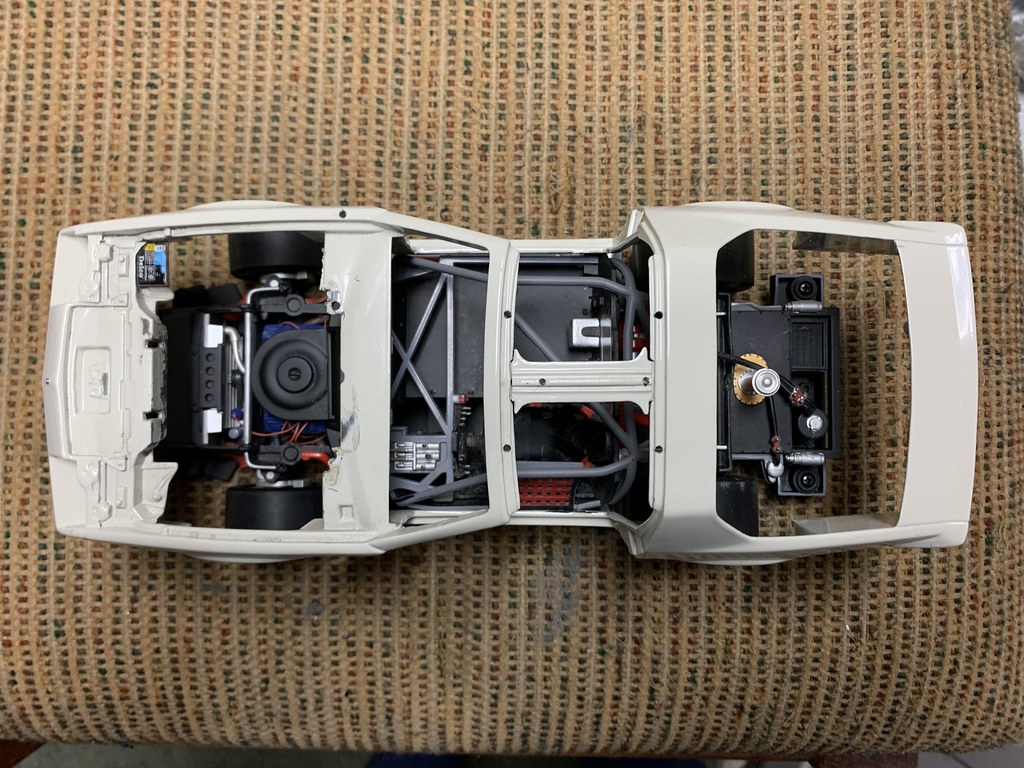

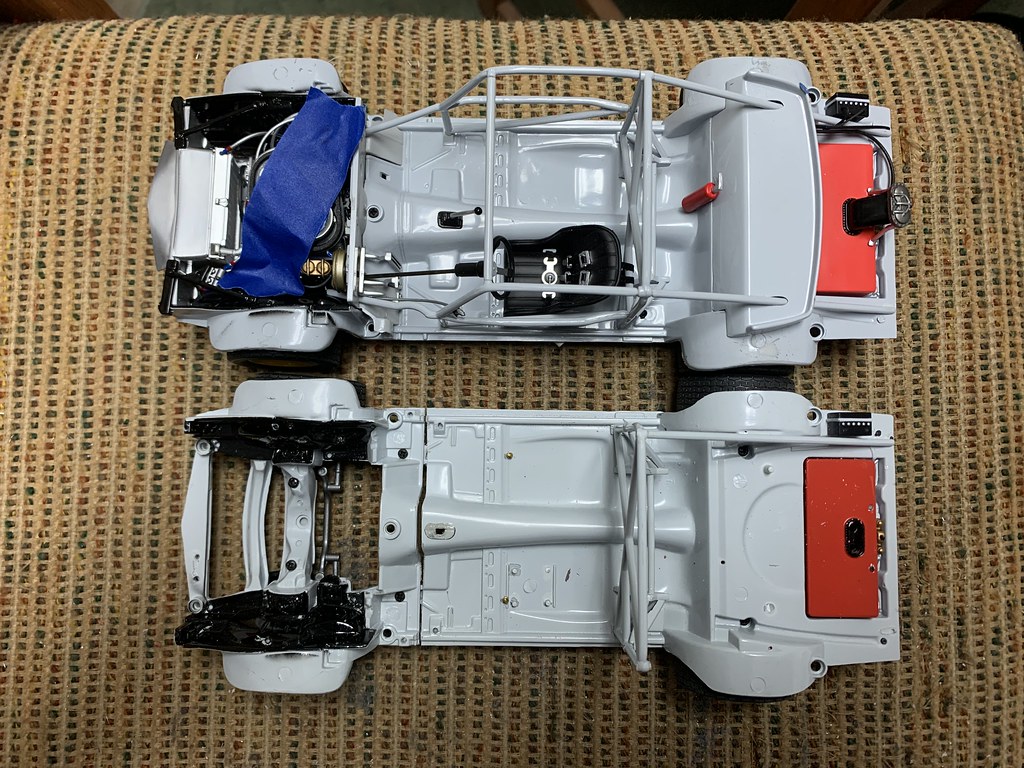

My donors will be a SunStar 1982 Camaro Z28, and a GMP 1996 Trans Am Camaro.

I’ll skip the boring disassembly process and go right to the staging of the two donor components.

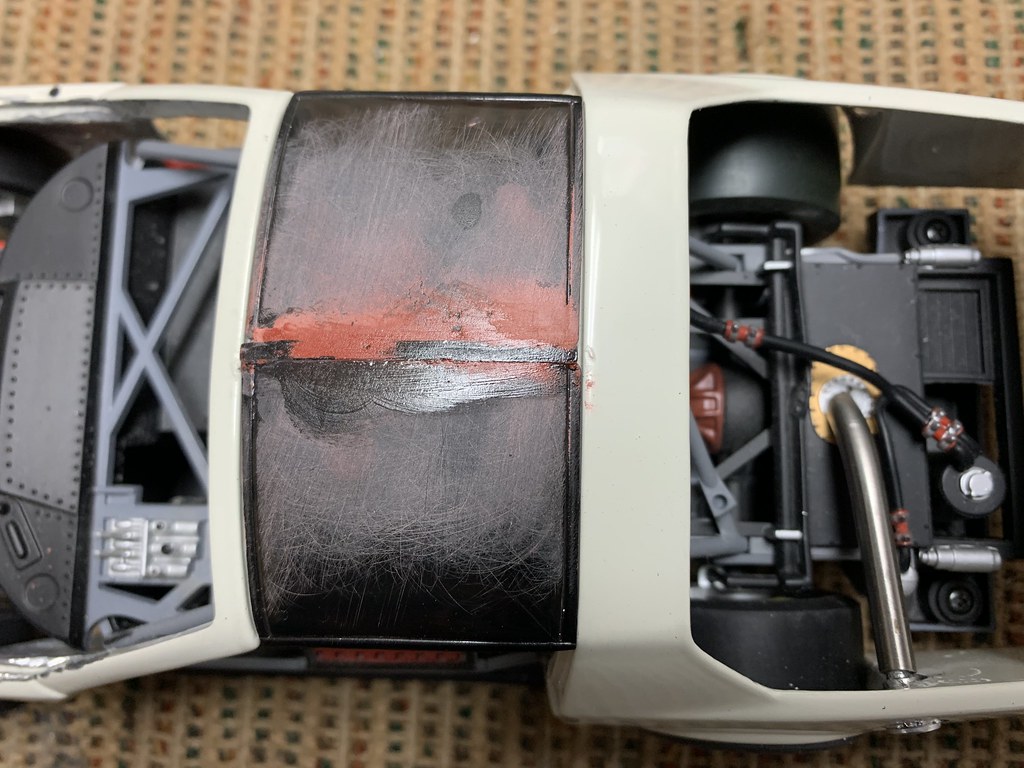

Here you can see from above that the componentry will be a nice fit.

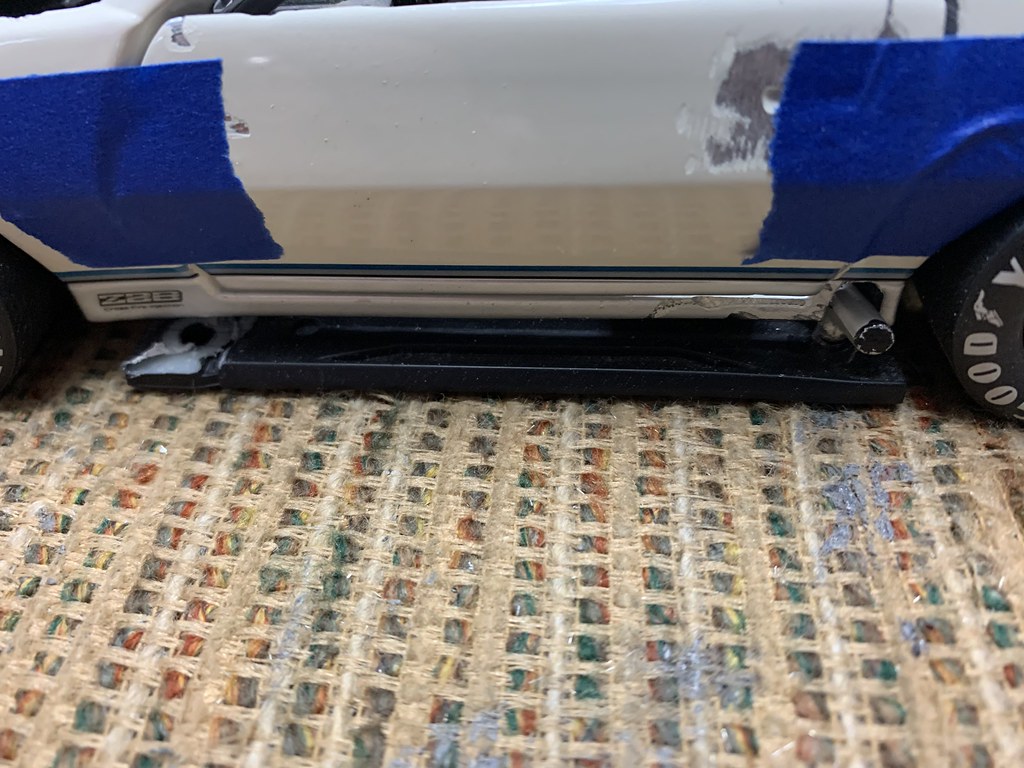

Here from the side you can see that there are already some conflicts which don’t allow the body to seat onto the chassis.

Going to be some major Dremel work.