This is a reall big model. Compare the difference of the B-29 box anf the box of an F-86. Check out the size difference between the B-29 and the P-47. The B-29’s wing span is 36 inches. This is also an old model with typical old model issues; ejector marks and a lot of flash. It also has raised panel lines.

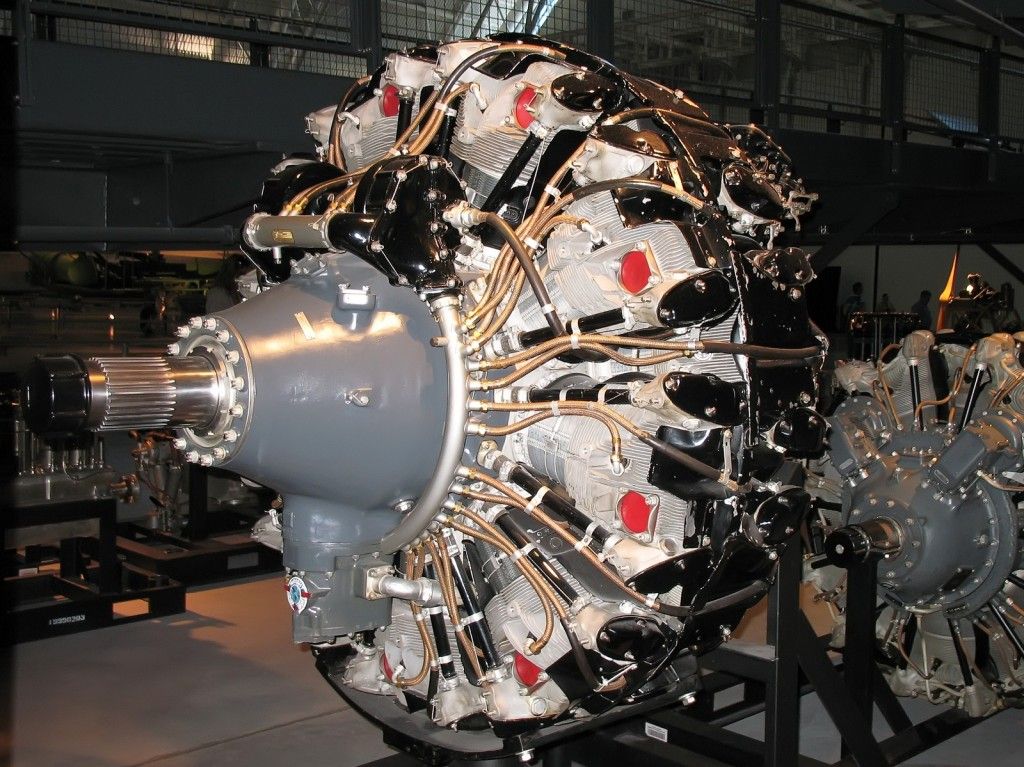

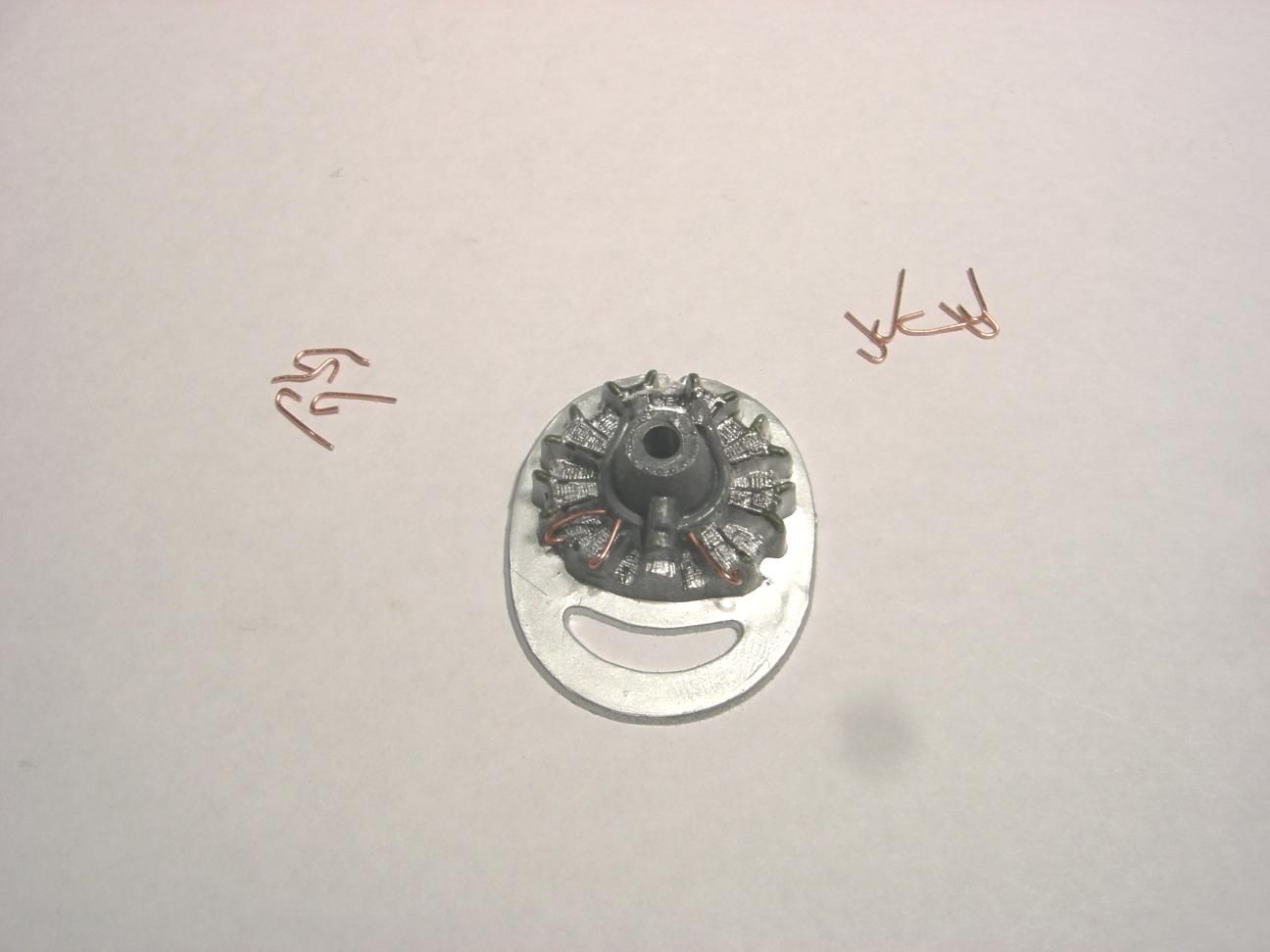

Since this is a big model, it will need some extra detailing and some “bling”. The cockpit is going to be dressed up with Eduard’s upgrade kit and the stock wheels/tires will be replaced with resin wheels/tires. I’ll add metal fuel lines to the engines and metal brake lines to the landing gear for some extra “bling”. The fuselage and wings will not be painted, instead they will be finished in Bare Metal Foil I figure that I’ll need 6 to 7 sheets of foil. Finally, rivets will be added to the wings and fuselage.

Okay, let’s get started by building the main wings.

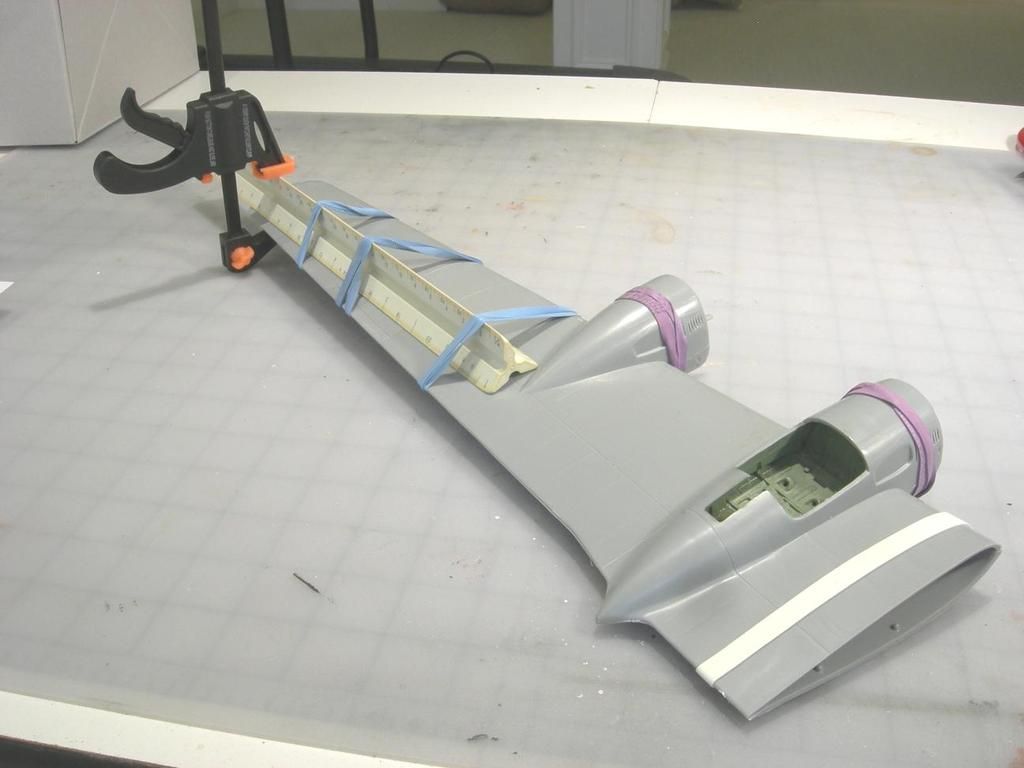

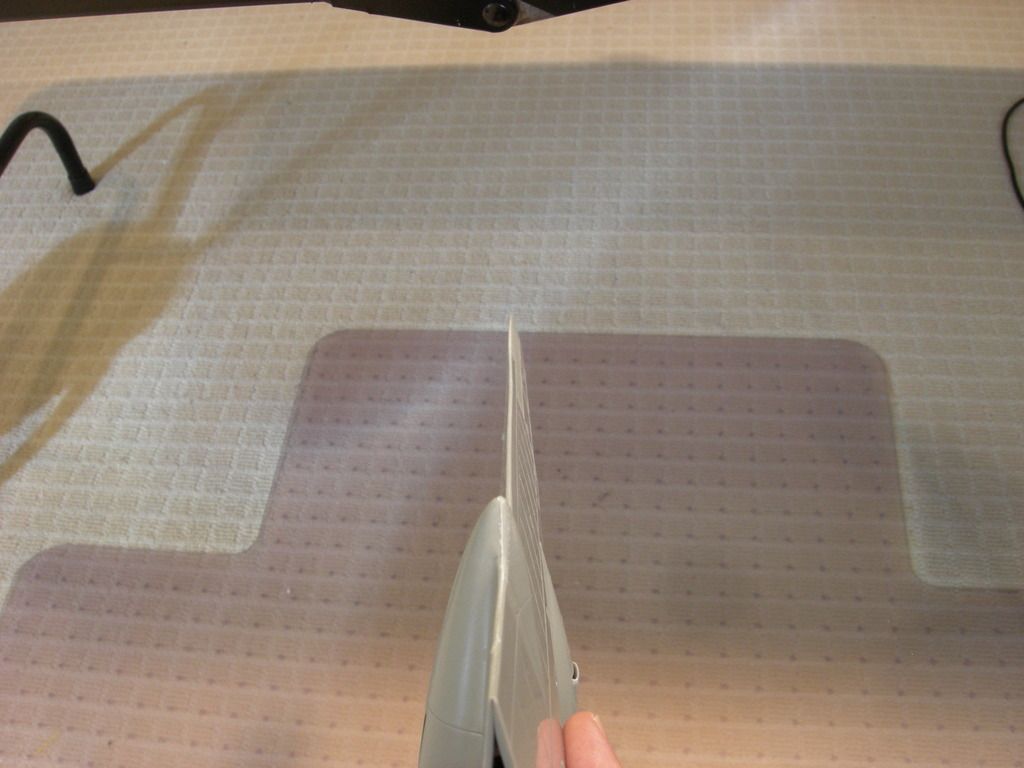

The landing gear box was painted Tamiya cockpit green. The internet indicated that this box was painted in a number of colors, green, yellow and silver. I used green BIG PROBLEM 1: the wings appeared to be warped. I decided to use my old ‘architect’s scale’ along with a clamp and rubber bands to force the wing into being straight.

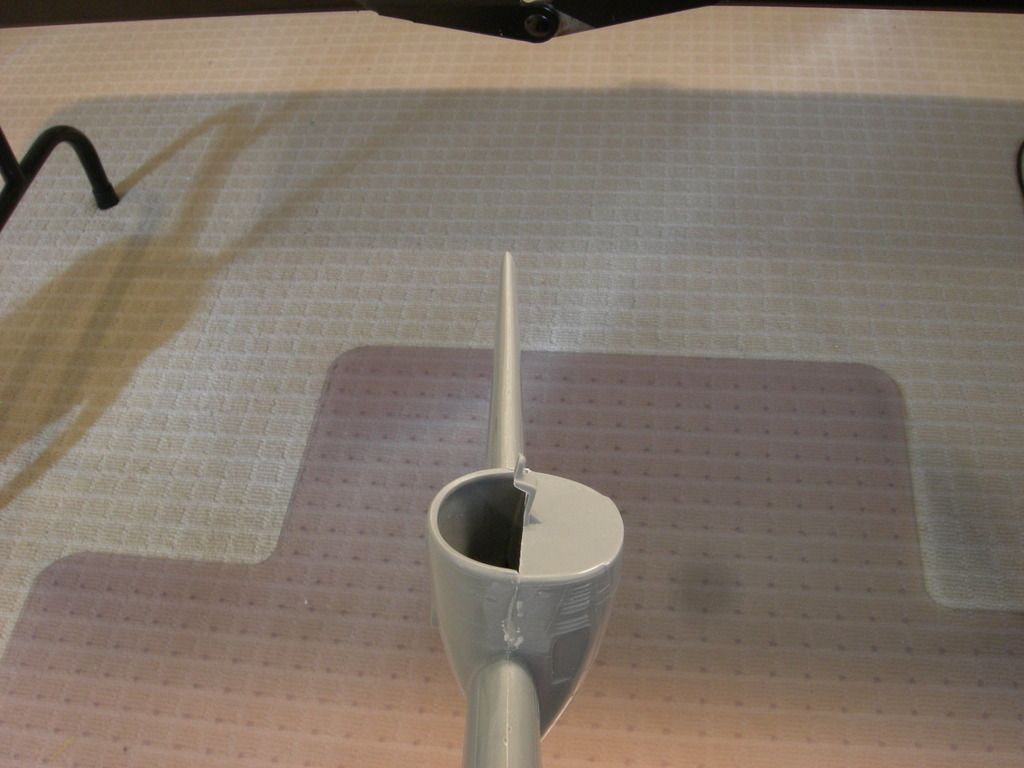

BIG PROBLEM 2; There is a huge gap at the engine nacelles. Really nasty! I decided to try sanding the wings adjacent to the nacelles to fix this issue.

A little sanding really solved a big problem. After the cement cures, I’ll fix the joint between the two wing halves with filler.

After the glue dried and after a little sanding, the wing came out nice and straight.

I started on the cockpit while I worked on the wings. The cockpit was upgraded using photoetched parts from Eduard. Photos from the Internet indicate that the cockpit was painted a number of different colors, I chose Tamyia Cockpit Green. After the paint dried, I dry brushed Testors’ silver and black to add the impression of wear an tare.

Update 4-27-17, Building the Landing Gear

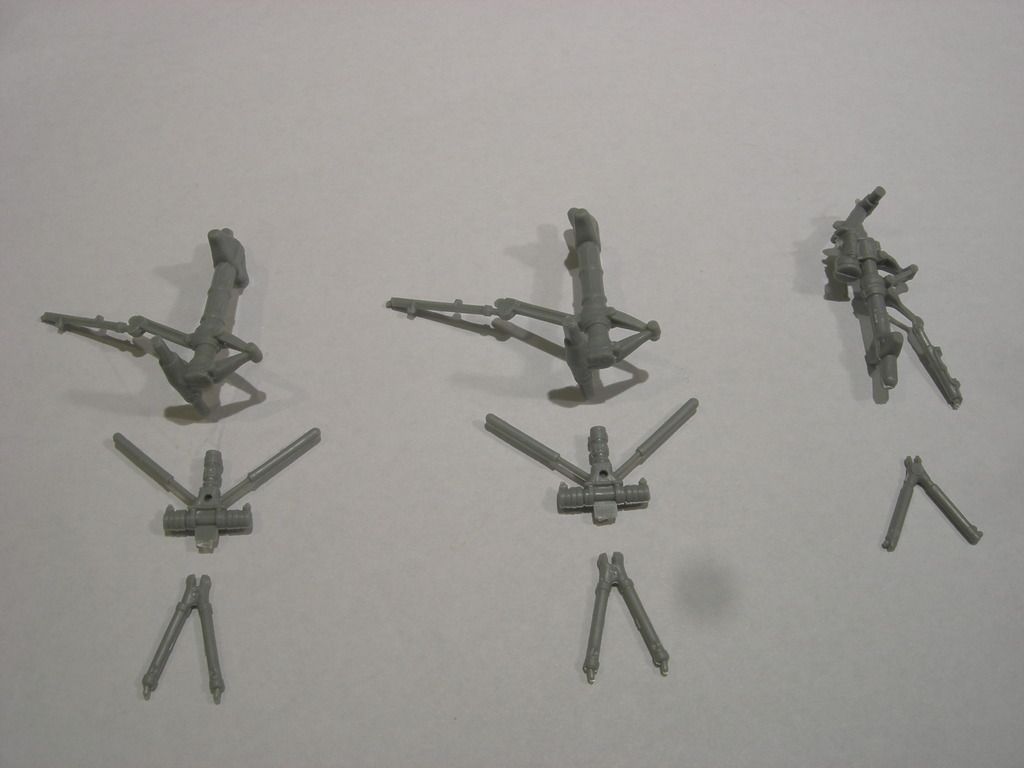

There ared three components to each landing gear. I’m going to start with the front gear.

There is a lot of flash that needs to be removed. There is also some piping that needs removal.

The gear looks pretty good after all the flas is removed. I drilled holes in the joints per photos on the Internet.

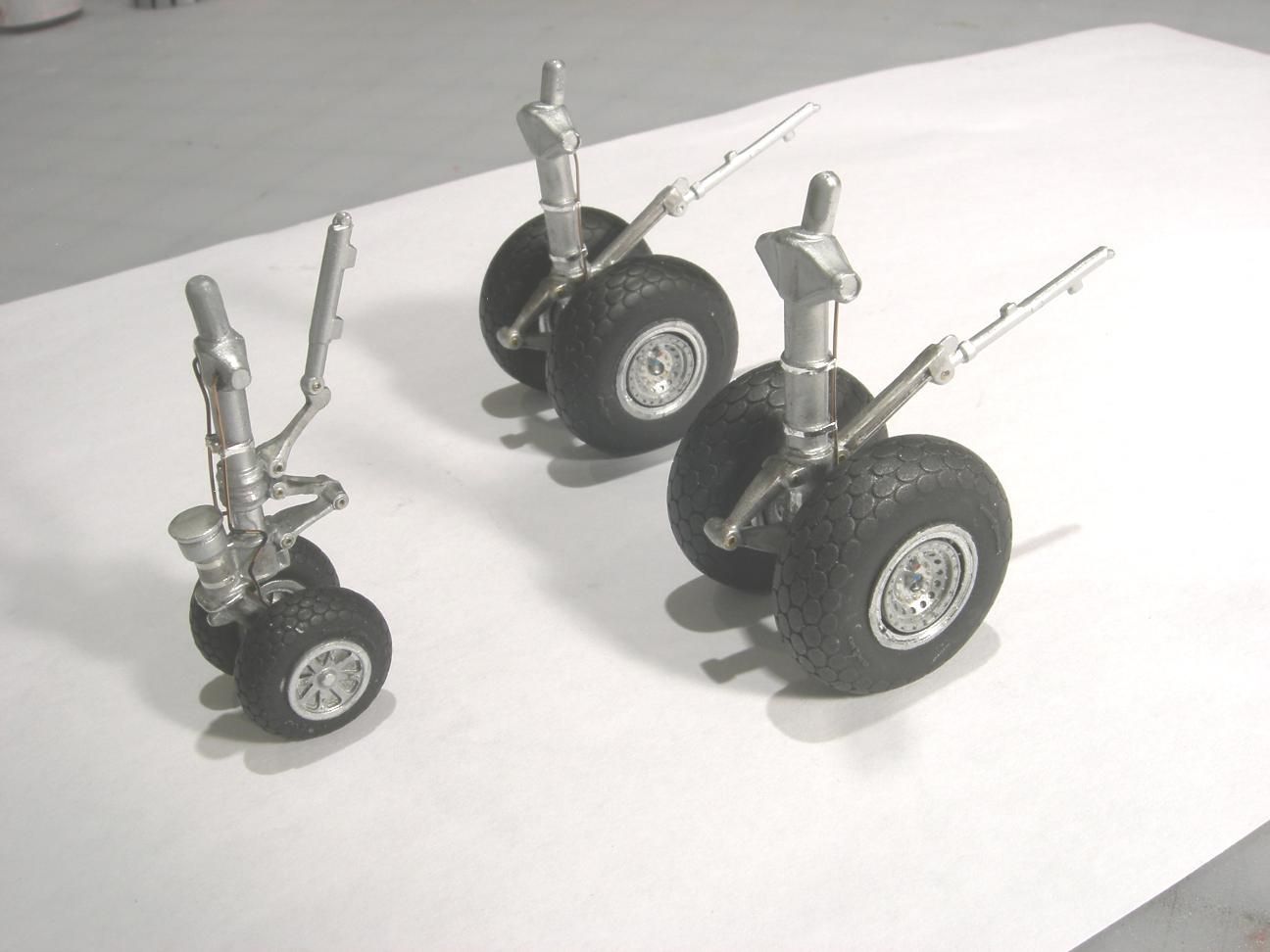

I painted the gear with Testors’ Aluminum. After that dried, Testors’ Flat Black was dry brushed. Next came dry brushing Testors Chrome Silver. The landing gear is pretty large so I added some ‘bling’. Brass paint was applied with a toothpick at the joint bearings. The brake piping is brass wire. According to photos, the piping extends into holes in the top casting and into the wheel bearing hub. The brake piping is held in place with a small piece of Bare Metal Foil. Per photos, two clamps held the damper’s (shock absorber) fluid container to the landing gear. I used two pieces of Bare metal foil to simulate the clamps. The resin tires and wheels are by Eduard.

UPDATE 5-3-017

I finally finished the main landing gear. AGain, the tires and wheels are by Eduard. The painting, highlighting and the installation of brake lines is similar to how I did the front gear. The additional detailing adds a lot to the appearance of the gear.