Hi all,

I purchased 1/48 resin tarmac section for a display. Gave it a shot painting, but it doesn’t look “concrete-ey” enough to my eyes. What can I do to make this look more realistic?

Would appreciate any and all advice.

Thank you!

Mark

Hi all,

I purchased 1/48 resin tarmac section for a display. Gave it a shot painting, but it doesn’t look “concrete-ey” enough to my eyes. What can I do to make this look more realistic?

Would appreciate any and all advice.

Thank you!

Mark

A friend who was a professional architectural model builder gave me a neat tip:

After painting the concrete a warm gray, take a spray can of flat black and tan, then holding them about 18" from the base, lightly spray them simultaneously. You want to get a light, spattery drift. It sounds crazy, but it really works! But do a trial run on some cardboard to get a feel for the process.

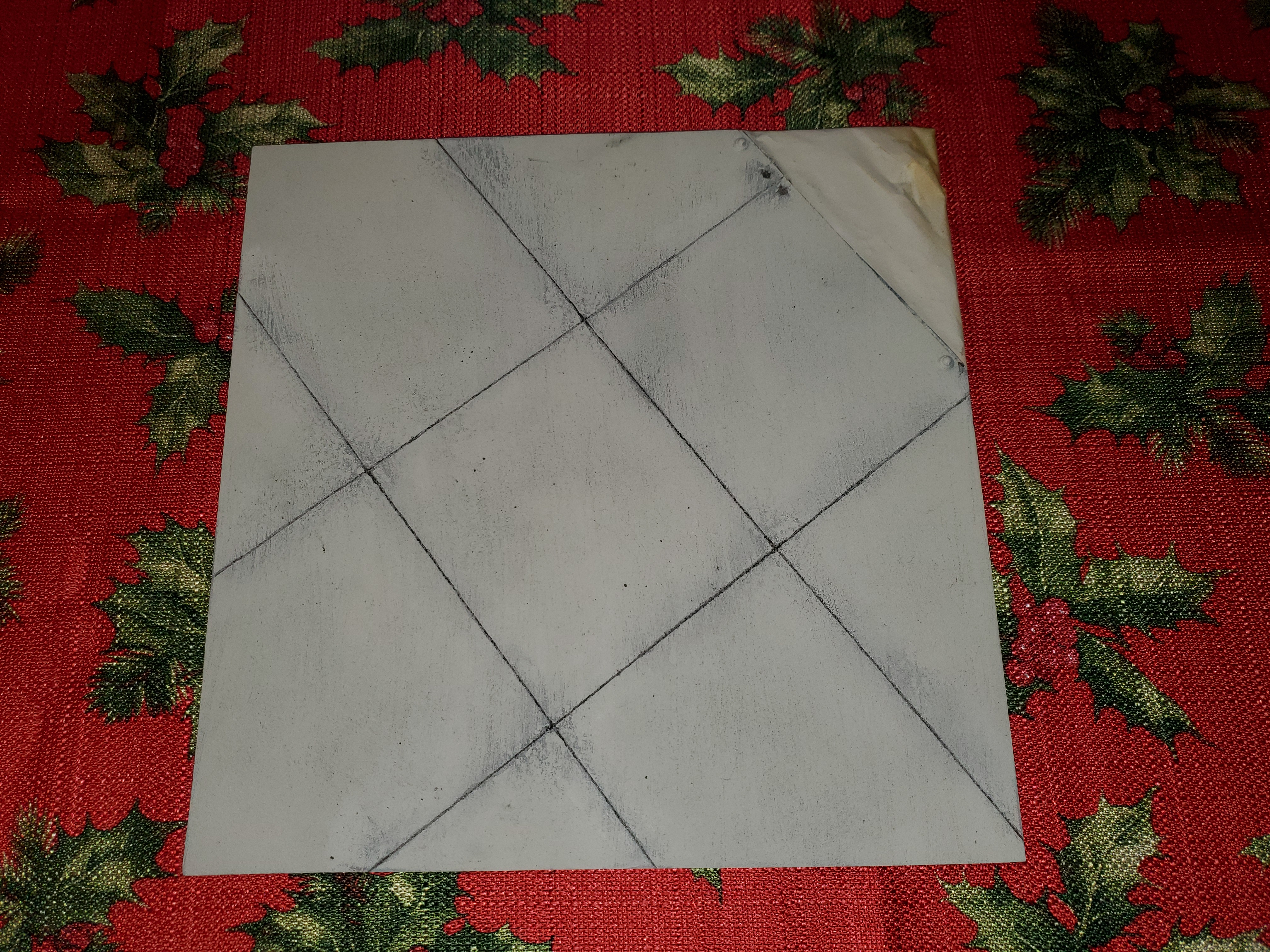

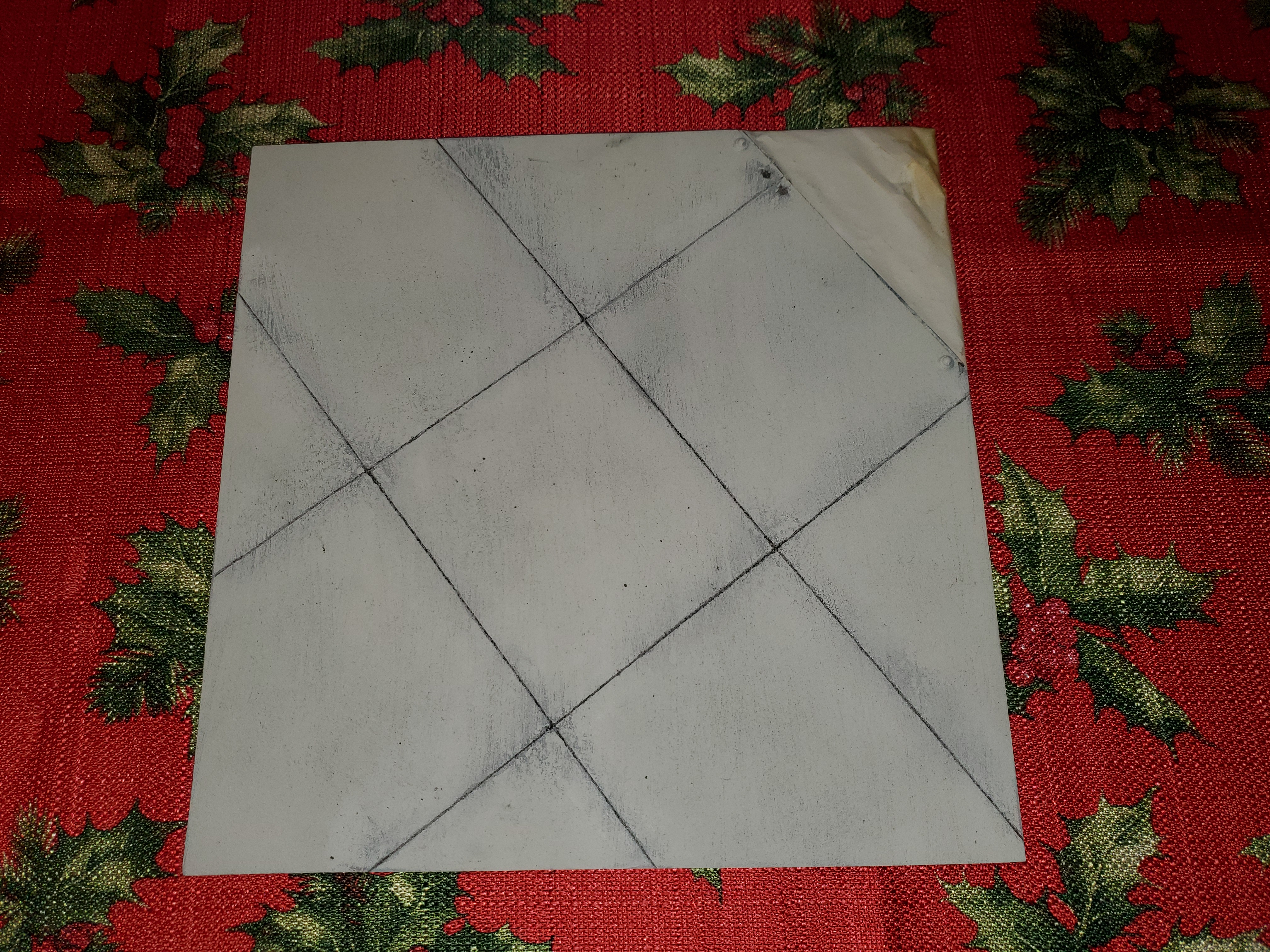

In the photo below, I painted sheet plastic with testors Camouflage Gray, then did the spatter thing as described above. The texturing you see is entirely the paint effect.

HTH

G,

That technique worked perfectly! Results were very nice.

Thanks for the tip!

Mark

Title was a tad misleading.

Tarmac is a contraction of tar-macadam.

Which is a specific form of pavement created by starting with a compacted gravel base, laying a liquid “tar” (bituminous amalgam) over that, and finishing with a wear surface of gravel over that. That mixture is rolled together to fully cement the wear surface to the subgrade.

The color is based on the color of the wear surface gravel (whcih can be used for creative effect for driveways and the like). As the material weathers, the black tar may fade to a pale brown, to mid gray matrix about the surface gravel.

Tar-macadam is very similar to asphalt paving, except that, with asphalt the tar is melted and the the gravel (a finer grade) imersed in that tar base, and the resultant material laid in complete layers in a single pass.

It’s color is nearly always a black or blue black to a deep, deep brown or black brown color. This can fade to a speckled gray as the tar is worn off the aggregate within.

Both of those pavements are poured in continous strips, and the edged melded together, leaving few, if any, seams. Such seams as exist, and all cracks are sealed with a flat black polymerized tar sealant.

Concrete takes its color from the Portland Cement used in it’s mix. Portland cement–a kiln-heated lime product–is mixed with sand and gravel aggreate. The addition of water “activates” the adhesive nature of the Portland, which glues the stone and sand together.

As a constructed stone product, concrete is very strong in compression, but weaker in tension, whcih necessitates the used of steel reinforcement. It also recommends placing the concrete in explicit panels to maximize those stengths.

Those joints have sealant applied, to keep water out of the all-important subgrade. Those sealants can be white, cream, tan, or black in color. Concrete of certain eras and uses will have expansion joints of rot-resistant wood like cedar, teak, or redwood–thos invariably have a black sealant applied, and are very straight and true.

Concrete can be a very pure white, almost every shade of pale gray, both war mand cold gray.

To keep things interesting, for very heavy loads, it is not uncommon to use concrete as a sub-grade surface with either asphault or tar-macadam over that. Joints, especially expansion joints in the concrete below must needs be replicated i nthe asphaut or tarmac above.

Hello!

Capn - it’s so cool how I can always count on you for those technicalities I always wanted to check out bud didn’t have the time to research!

Now for dios - I have two cool methods for you.

concrete: finish the surface in flat white - acrylic flat white will work, but some wall-finishing-putty works better, you can apply thin layer of it and sand flat if you want to. You can also work in seams and cracks. Then apply black wash over that. The results look like this:

asphalt - use fine sandpaper, about 1000 grit or finer of the right colour. Tar seams can be painted in, as well as stains or white lines:

Hope it helps, have a nice day

Paweł

Though it may be technically inaccurate, “tarmac” is a commonly used term. [H]

For the technical and non-technical alike, you can substitute the term ‘apron’ in lieu of tarmac, as apron is non-specific as to its construction. In general usage, you have runways, taxiways, and aprons.

Concrete airfield runways, taxiways, ramps, and aprons have many different colors and textures. Passing through Sea-Tac on Monday, I noticed that it has a brushed (gravelly surface) finish for nearly most surfaces. After walking through Lowes, I noticed an idea for concrete diorama bases. Why not use concrete board for a ramp surface as some have very smooth surfaces and have the “proper” color. Some even have minute cracks in the surface.