I thought of posting this in the ‘Scratchbuilding’ forum, but on the suggestion of Modelcrazy (yet another Steve) I decided to put it here. The build is being done for the ‘Boeing Build’ group build, with crossovers to the ‘Floats & Boats’ and ‘OTS (1/72) Small Is Big’ GBs.

I joined the forums about a month ago looking for some help, and immediately wondered why I didn’t sign on years earlier. Mainly because most of my models are built for gaming, and not really meant for serious display That said, when I saw the Boeing Group Build I remembered I have an old Merlin kit of the Boeing Model 40. Then I looked around and found that there was a much better resin kit. Then I found kits for the Boeing 80 tri-motor and the Model 200 ‘Monomail’. All of these were running through my head when I re-read the thread from the beginning and realized that it was done in honor of the first flight of the first Boeing aircraft, the Boeing & Westervelt Seaplane, on June 1, 1916.

I did some looking around and found that nobody was tackling this subject, and decided I had to try. It has been a couple of weeks at least since I announced this, and wondered if people were starting to wonder if I was serious about it. The delay has mainly been due to finishing up another project and, since there was no kit available, what it would take to make it happen. Lots of thinking, lots of research, almost no action.

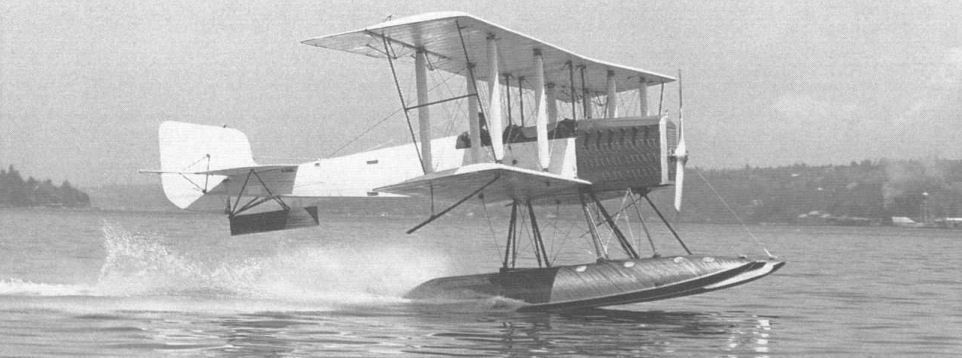

The plane itself should be easy enough, being of fairly straightforward rectangular cross-section. I found a lot of good photographs of the original two planes and the 1966 full-sized flying replica which now hangs in the Boeing Museum.

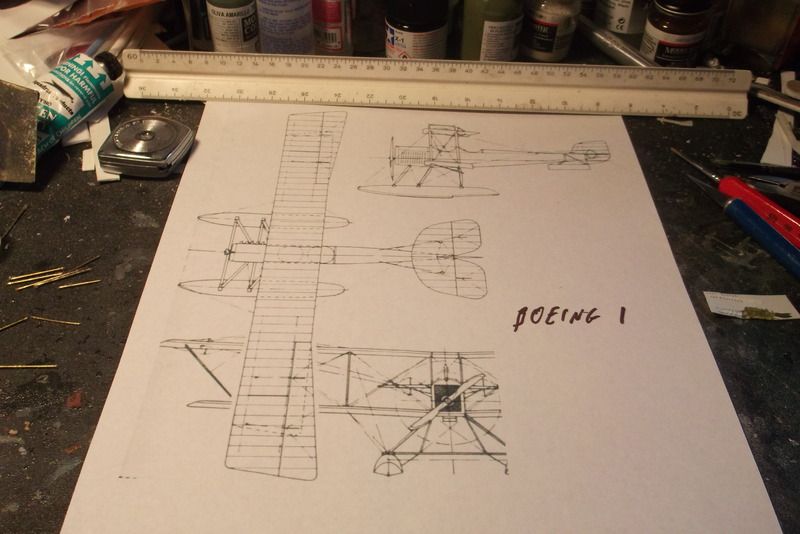

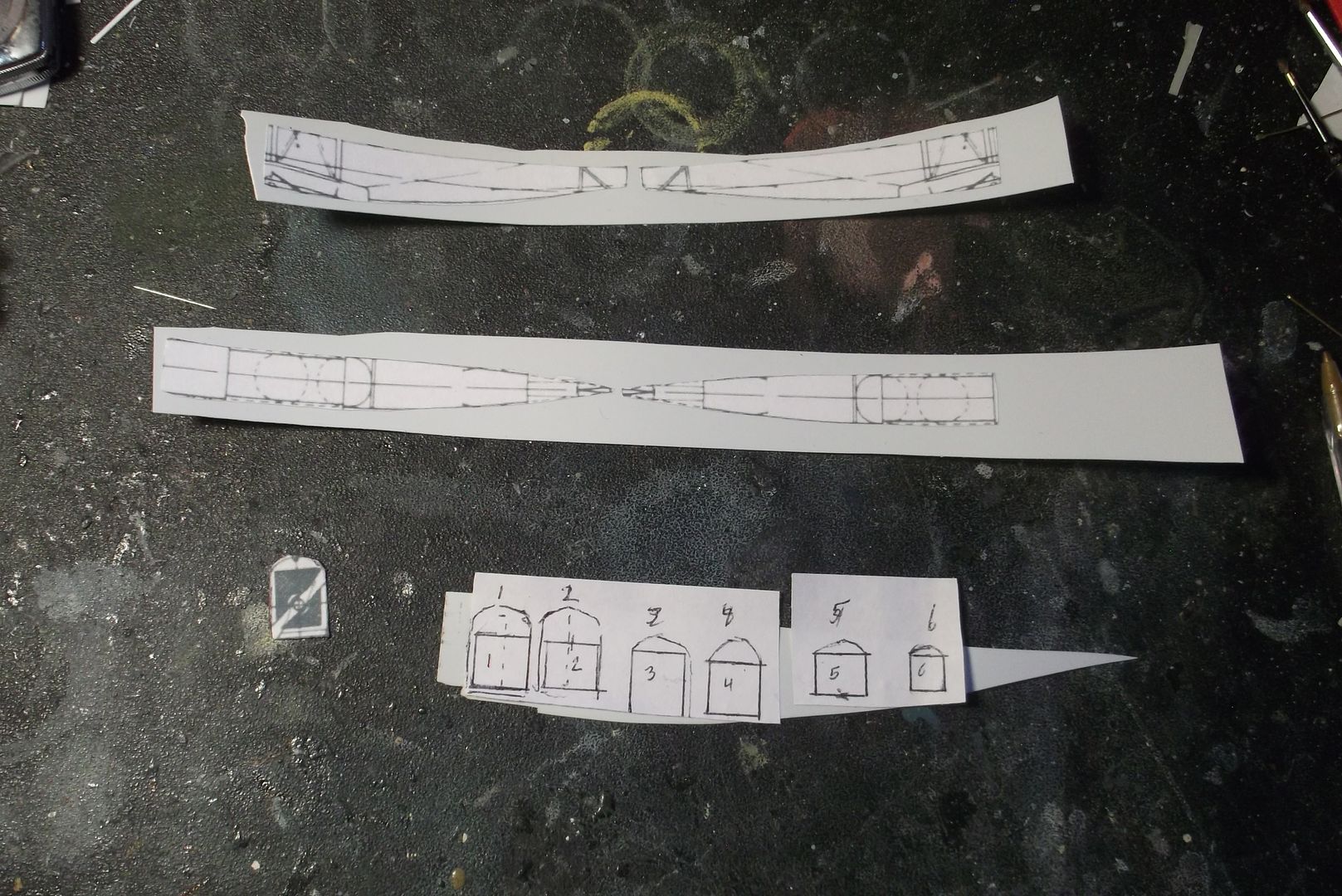

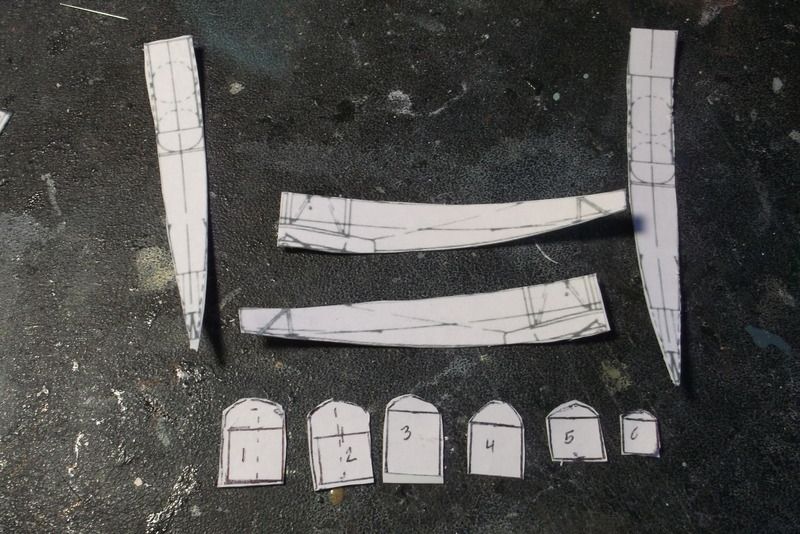

I also found a good set of 3-view plans. I don’t know how accurate they are, but they look pretty good. I used my favorite desktop publishing program, PageStream, to resize them to proper 1/72 scale dimensions given by Peter Bowers in his book Boeing Aircraft from 1916 to the Present. I printed out 4 copies - one for a master and three more for cutting out for sizing the plastic version.

In the background is an architectural ruler I picked up when I took a drafting class back in 1975. It has six scales, the smallest being 60 feet to the inch, or 1/720 scale. Since this translates easily to 1/72 it comes in handy for building in that scale, the only problem being that each scale foot is divided into 10 parts instead of 12 inches. I just ordered a real 1/72 ruler that divides into 12 inches and also does metric. It should be here soon.

That little bit started, I have three major tasks ahead:

-

The cockpit. I have no pictures showing the whole cockpit, though I do have a couple of partials. I emailed the Boeing Museum asking for help with the layout and seat construction. I’m still waiting on a reply.

-

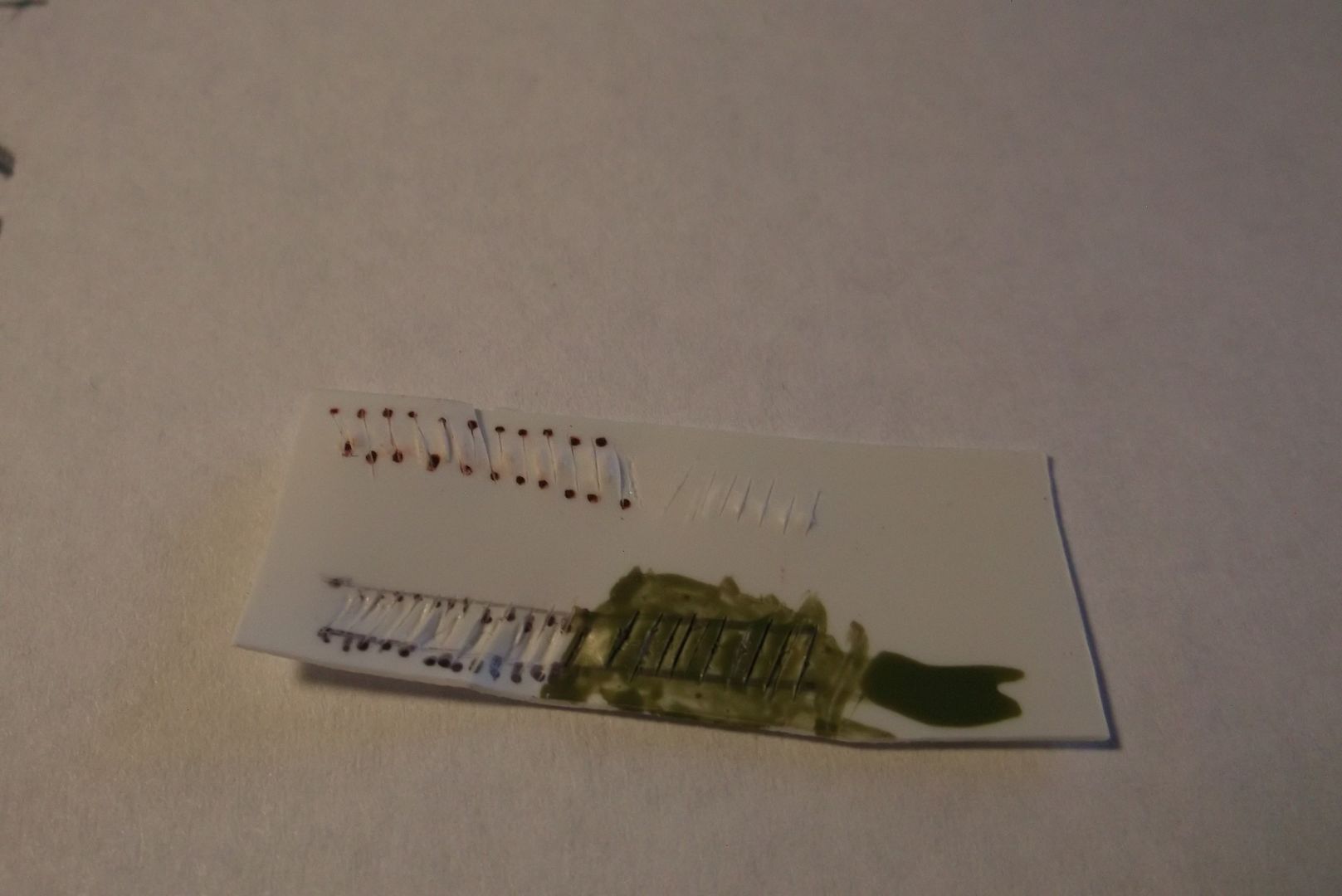

Louvres. The plane had three rows of thirteen louvres on each side of the cowling. I purchased some HO scale railroad louvres, but before they arrived i realized they were already wrong. The originals were slanted to the rear, and the ones I ordered were almost certainly going to be straight. I’ve bee practicing cutting my own with varied results.

I’ve tried thin plastic. paper and even aluminum foil. Tomorrow is a trip to the local hobby shop to look at Evergreen quarter-round plastic rod.

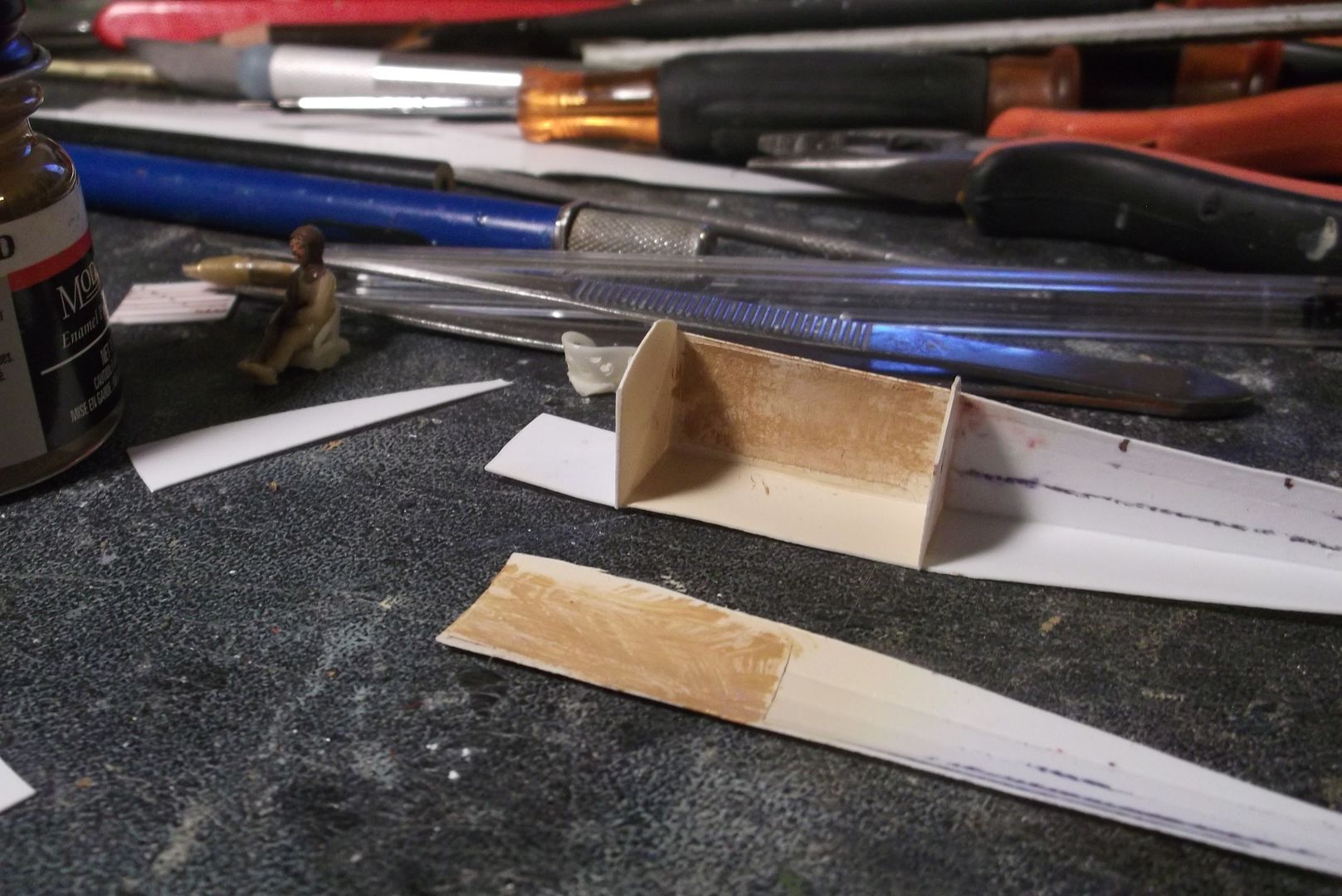

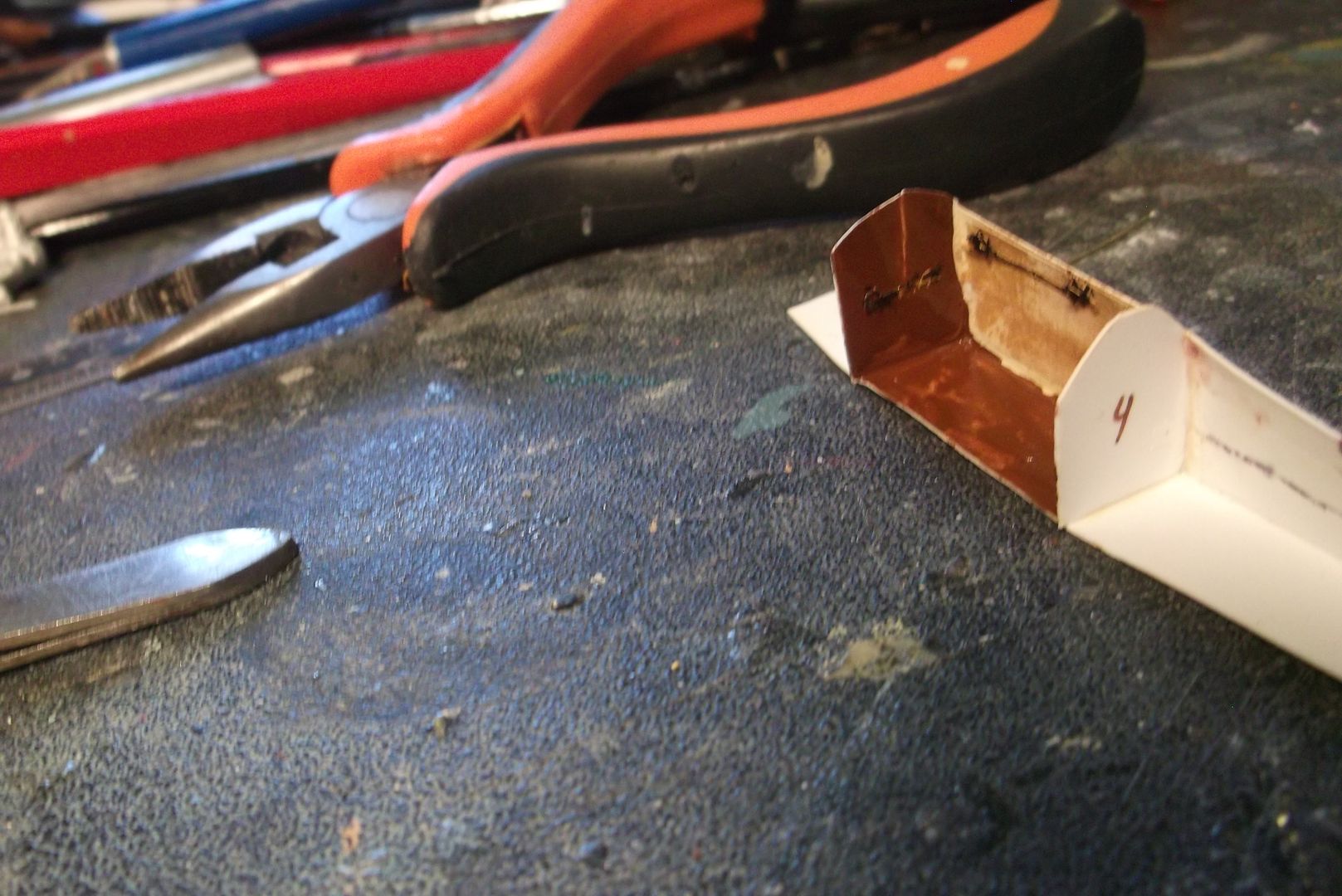

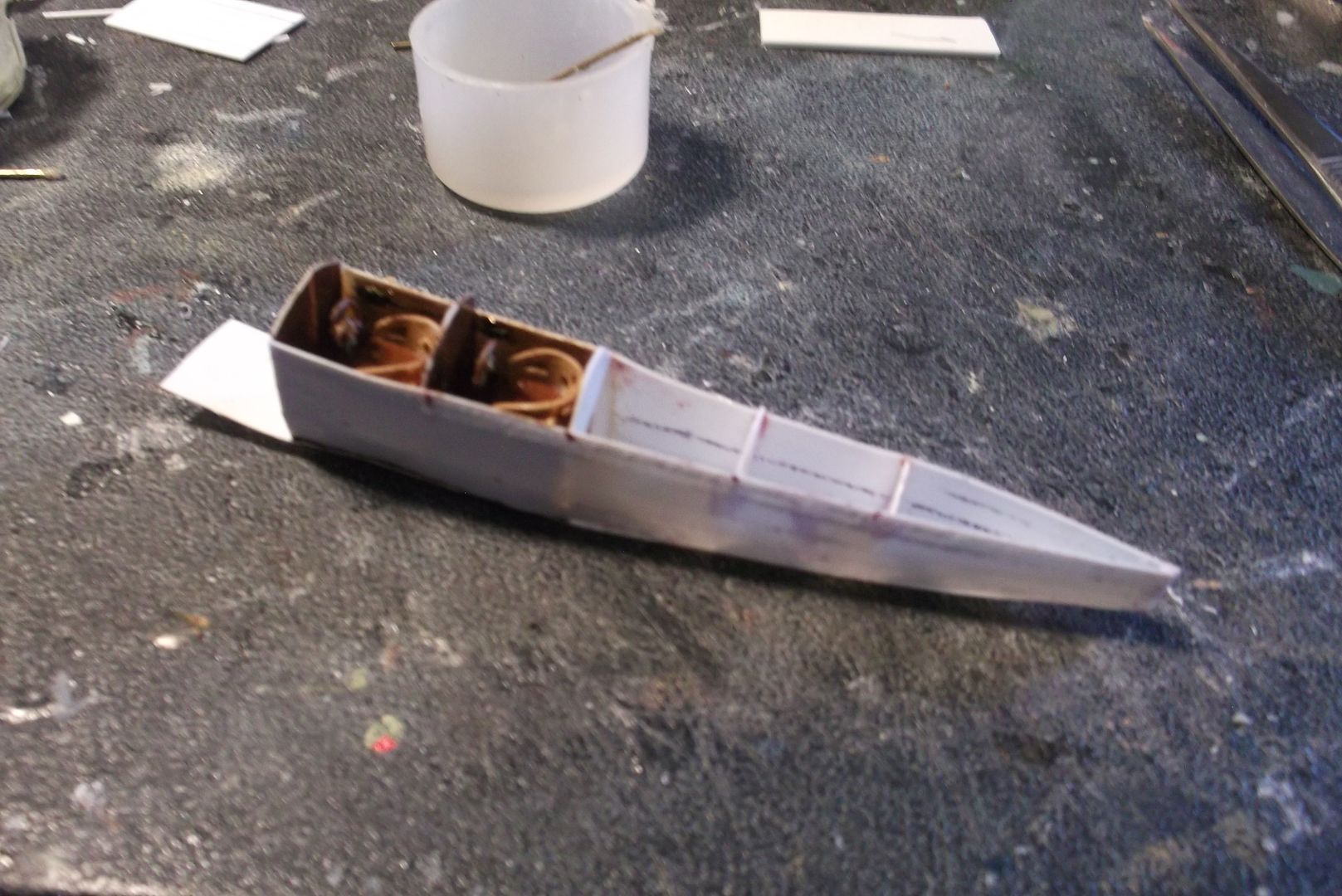

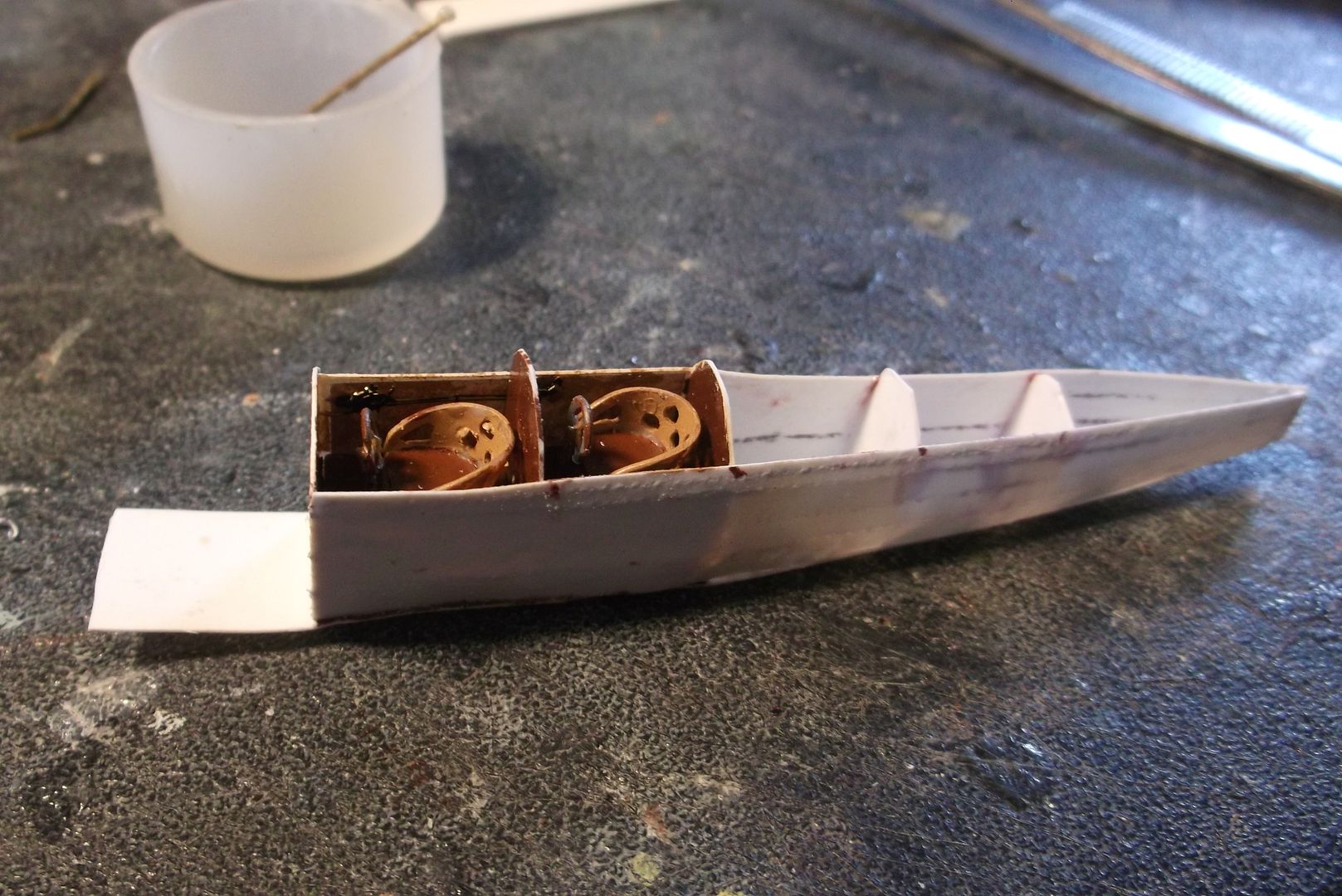

- The Floats. Finding some that are a close enough match to work from might get expensive, so I’m going to have to learn to make my own.

Anyway, though I only have the plans so far, much progress is being made inside my head.