I don’t have any problem with what material to use for the belts, it’s making those darn buckles and fastners please I need help or I’ll be headed for the funny farm, I don’t have far to go for one of those since there is one of those here in town…

Thanks,

CPO

ha…i was headed here to ask that same question[?]

Depending on what scale you’re working with and whether or not they are aricraft or auto could make a difference. Try using little bits from packaging aluminum, ie vaccuum seal tops off coffee cans or wine bottle foils- both have worked for me. It’s thicker than household alum. yet malleable. It can even be embossed. I’ve also used scrap bits of photo-etch aluminum and brass, too. Good luck.

Thanks RRV and another thing that I have a problem with is making the buckles, I work mostley in 1/48 scale air craft… ![]()

![]()

CPO

Hey Dude! I work 1/48 scale only. I ususally paint mine on the material I use for my seatbelts using a fine point toothpick or needle with chrome, silver, etc. paint. It works well and looks good too, especially when looking at it through a closed canopy. Otherwise, you’re only hope of making a convincing buckle is using photo-etched parts (which are available). I’ve seen tiny squares with the centers cut out and a thin piece of wire laid across it to simulate the buckle clasp. Again good luck amigo!

i take renolds wrap aluminum foil, fold it , acc it together. when dry, take a #11 blade and cut out your buckle. a little time consuming, but it looks good. check out my modified stock car at photobucket, under pibull63. its in the modified folder…steve

Thanks Steve, I haven;t tried the al. foil yet. Don’t laugh but the old man is a little bit slow but what did you mean, acc it together. We have a mental institution here where I live and they don’t know that I’m out. Also not sure that I can pull up photobucket, would like to see your pictures.

Thanks again,

Charles-- AKA Pat

hey bud, acc is an adhesive similar to crazy glue. when you fold the foil in half put a few drops of “acc” in the fold. press the fold together, so there are no wrinkles. the cut out the buckle and the adjuster here is the pic…hope it helps…steve

here is the pic…hope it helps…steve

Steve…thanks for the picture and the explanation of acc, I told you that I was a little slow.

Pat

I like making belts out of masking tape myself. Tear off a strip about 3-4" long, fold it onto itself and then use a metal straight edge and a #11 to cut small strips out. I used spare PE parts for buckles and hardware. This technique works well for me in all scales.

i use ribbon material from michaels. you dont have to apologize for being slow…were all here to help…steve

Thanks Scott I will try this method, this has been one thing that has really bugged me for some reason.

Thanks again,

CPO (Pat)

by the way pat, the seat is upholstered with an old pair of parachute pants that the kids outgrew…steve

Thats one of the sweetest things I’ve ever seen!!! Nice job! I didn’t even notice the texture until I went back to look again. Thats a nice touch. Thanks for sharing.

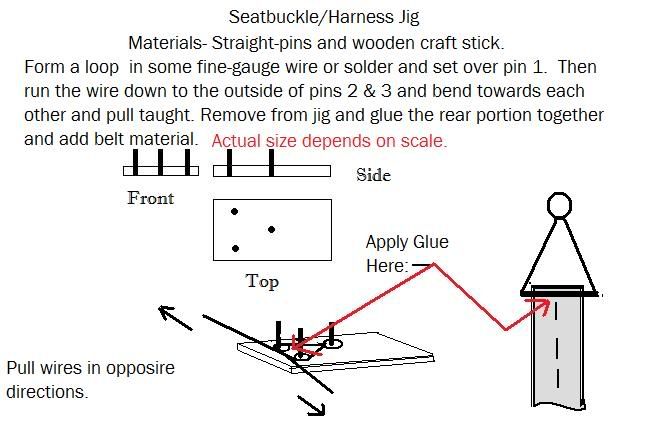

Here’s a drawing of one of the jigs I use for making harness hardware.

Get different shapes by arranging the pins in different patterns…

Thanks Hans… do you make a jig for the the buckles? I work in 1/48 scale, do not have any problem with the belts only the hardware. Will try this tonight…

Thanks,

CPO (AKA Pat)

Yeah, I just haven’t drawn a buckle jig yet… I’ll draw one up later…