I just resuscribed to FSM and I was wondering if any one could be so kind enough to take time when they are bord or when they have time to explain to me exactly how to do this process. I would love to start experementing with this…

Brett

I just resuscribed to FSM and I was wondering if any one could be so kind enough to take time when they are bord or when they have time to explain to me exactly how to do this process. I would love to start experementing with this…

Brett

Brett,

Resin casting can be quite simple…as long as you know what you’re doing.

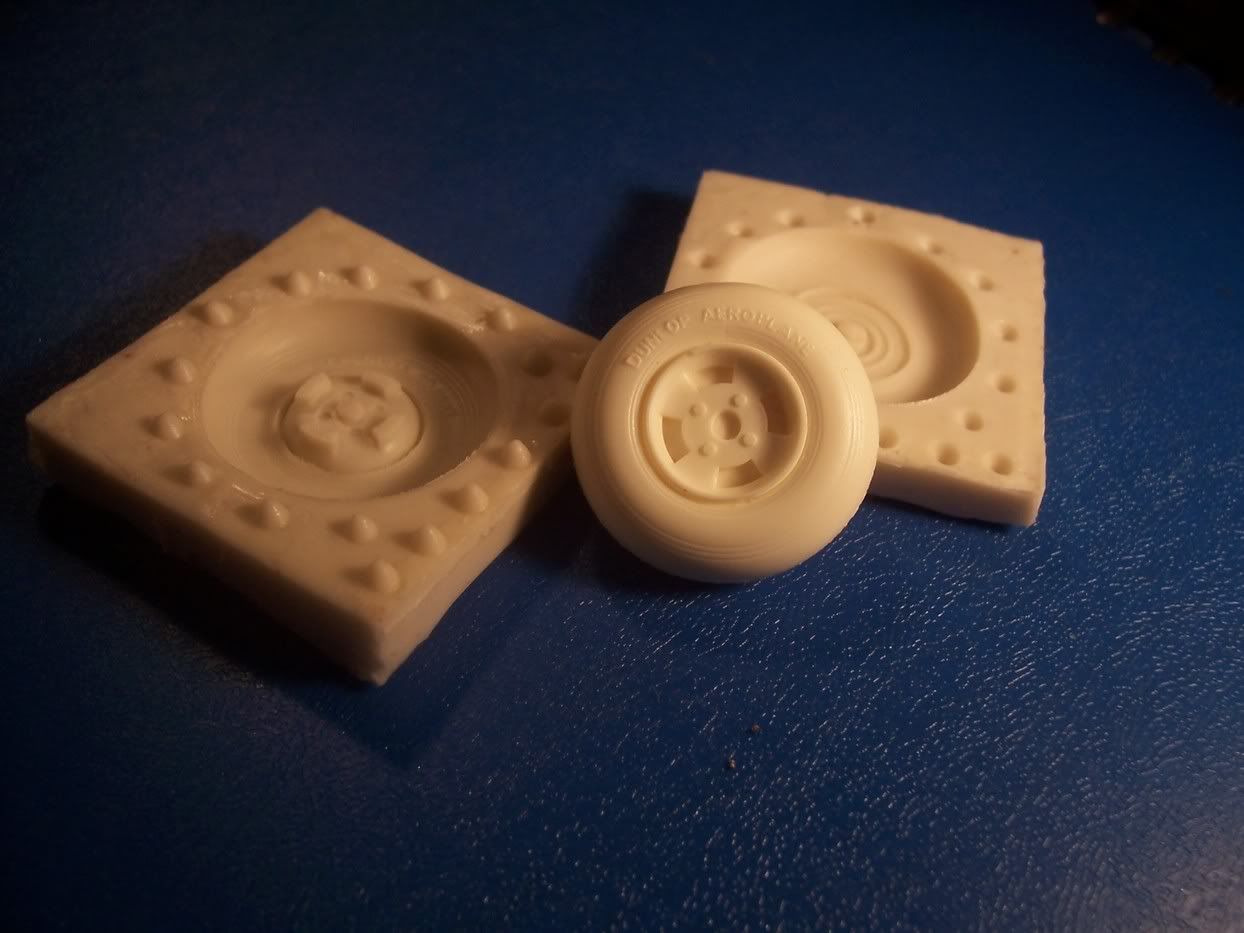

Your molds can be simple two piece molds like the 1/24 scale Hurricane wheels below…

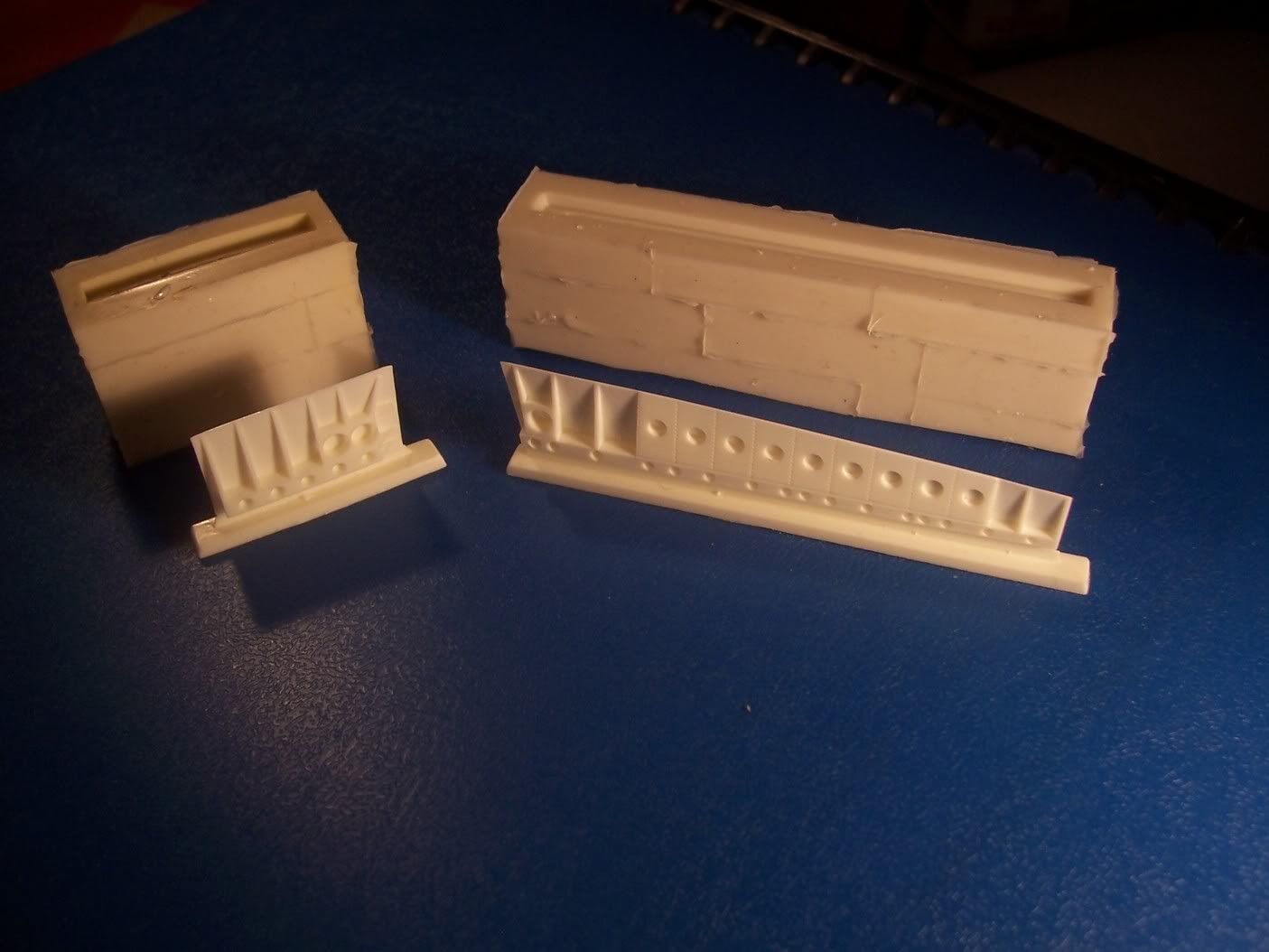

Or…it can be a very simple one piece mold for the Avenger dropped flaps below…

Or it can be terribly complicated and time consuming - like the Britten V-1000 below…it’s a resin copy of a 1/12th scale pewter kit…took me ages, and cost a packet…

Basically, you need a master - mounted on a plinth (for the one piece molds like the Avenger flaps) or buried to 1/2 depth in modelling clay for the two piece molds (for the Hurricane wheels).

Once the master is mounted or buried, build a little box (or dam) around the part, and in goes the RTV - Roon Temperature Vulcanising latex rubber - which comes in many hardness (Shore-A) ratings - very soft is best for delicate, detailed work.

When the rubber goes off, simply peel away the clay, lay down the wheel half (now half buried in the RTV), apply a mold release agent (a sprat that keeps the RTV from sticking to itself) and then pour more RTV over the other half of the wheel.

Once the rubber has gone off again, peel apart the two halves, remove the master, and your mold is ready to accept resin.

It really is that easy.

It’ll take time and a little experimentation to figure out the best method to use for each particular master you’ve got - sometimes it’s easier to mold things separately, sometimes in sub-assemblies.

The knowledge needed can readily be found on the net. There’s lots of places to look for info.

Try:

http://www.alumilite.com/ (lots of great stuff there)

http://www.resincasting.co.uk/

http://www.finescale.com/fsm/default.aspx?c=a&id=418

http://www.ninfinger.org/~sven/models/rms_tips/resin_cast.html

Mate, I’ve been doing this for years with fantastic results (the Britten speaks for itself, I think)- have a look at those sites - and if you have any questions about getting started on a project, just email me. I’ll help in any way I can. I’ve got a digital camera, so I can do a sort of online tutorial with some projects to help you out.

Anytime, mate - just shout and I’ll do whatever I can to help.

WOW Thanx soo much and that tutorial would be great. thanx alot for those links. I’ll take a look at them.

Cheers, Bret

Lee, that’s impressive! awe-inspiring!

Brett, here’s another site with good tutorials. They have good products, too, and are very helpful if you give them a phone call. Bare-metal

Thanx again guys. But another question!! If I have my master as a resin that I want to duplicate but want it to have more detail than the original one. what do I do? like for instance, what does True Details do, Verlinden and so on?? Thanx

Bret

What ever the detail is on the master part it will be duplicated too the Rubber and then to all of the parts made from the mold. If you need more detail on a part add it to the master before you pour the rubber.

ok thanx for the input