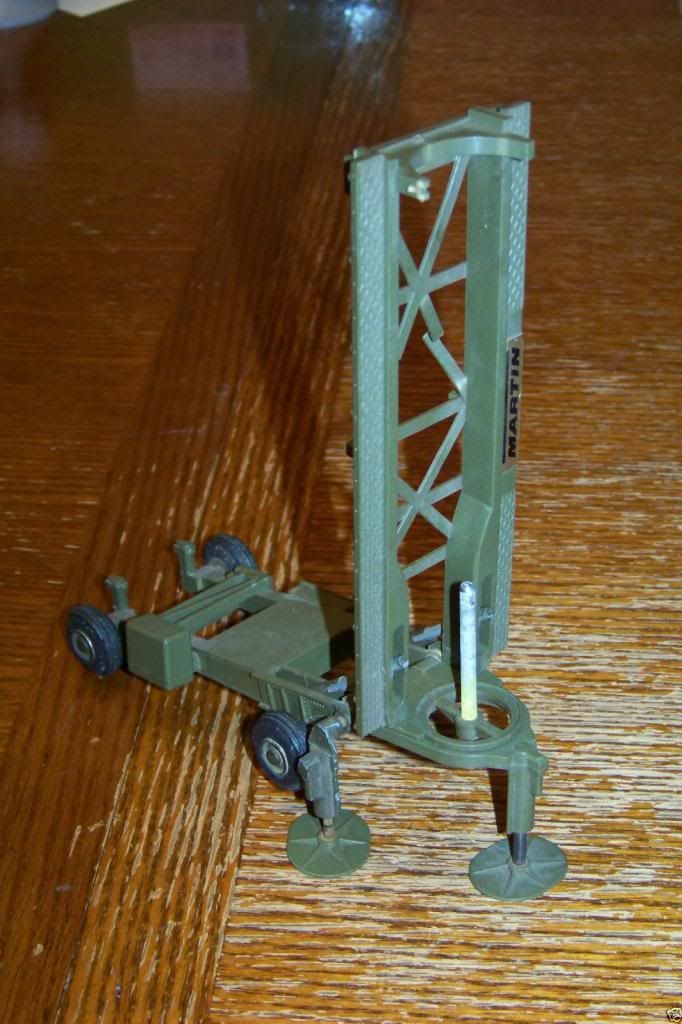

I recently acquired a Topping model of the Pershing 1 Missile and Erector - Launcher 1n 1/32 scale. I was a Pershing Missile Erector - Launcher Operator in A Battery, 3/84 Artillery In Neckarsum, Germany in 1967-68. I’ve always wanted to model my Army “gun” and this will give it to me. I have modeled an M474 vehicle which carried the missile and associated equipment.

First, some background on the Pershing 1 …

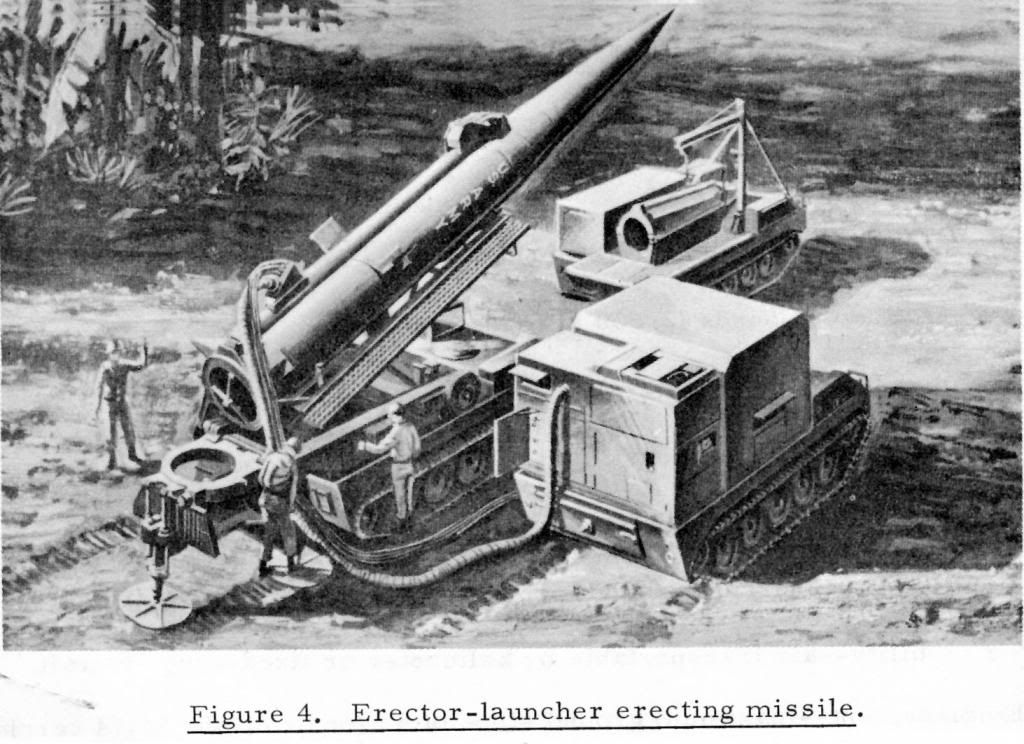

The Pershing is the U. S. Army’s longest range field artillery guided missile. In 1958, after the development of the first generation of missiles, which included the Redstone missile system, the Army determined that sufficient advances had been , made in missile technology to warrant the development of a completely new missile system to replace the Redstone. This new system, named in honor of General John J. Pershing and developed with the Martin Company as the prime contractor, utilizes many “state of the art” advances which provide greatly increased mobility and range and allow a significant reduction in size, weight and reaction time. Other outstanding improvements include ground support equipment designed for maximum tactical and strategic mobility, electronic computation of firing data, and automatic test and checkout equipment. The Pershing system also includes a specially designed communication set which is unique within the artillery and allows extremely reliable communications over great distances (99.9 percent reliability at 160 kilometers). The Pershing is normally deployed in general support of a field Army.

CHARACTERISTICS

a. The Pershing field artillery ballistic missile has the following technical characteristics:

(1) Length --34.8 feet (10.38 meters).

(2) Diameter–40 inches (1. 02 meters).

(3) Weight–IO, 275 pounds.

(4) Range–185-740 kilometers. .

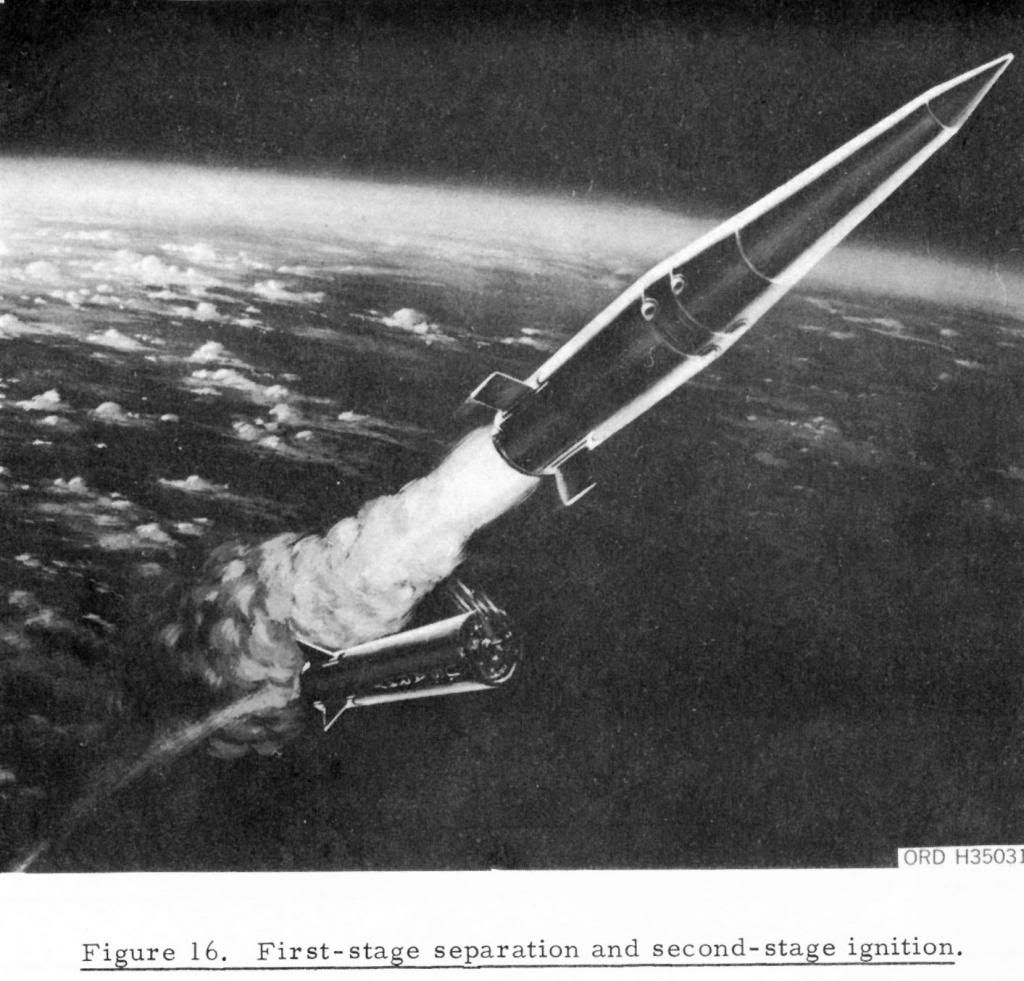

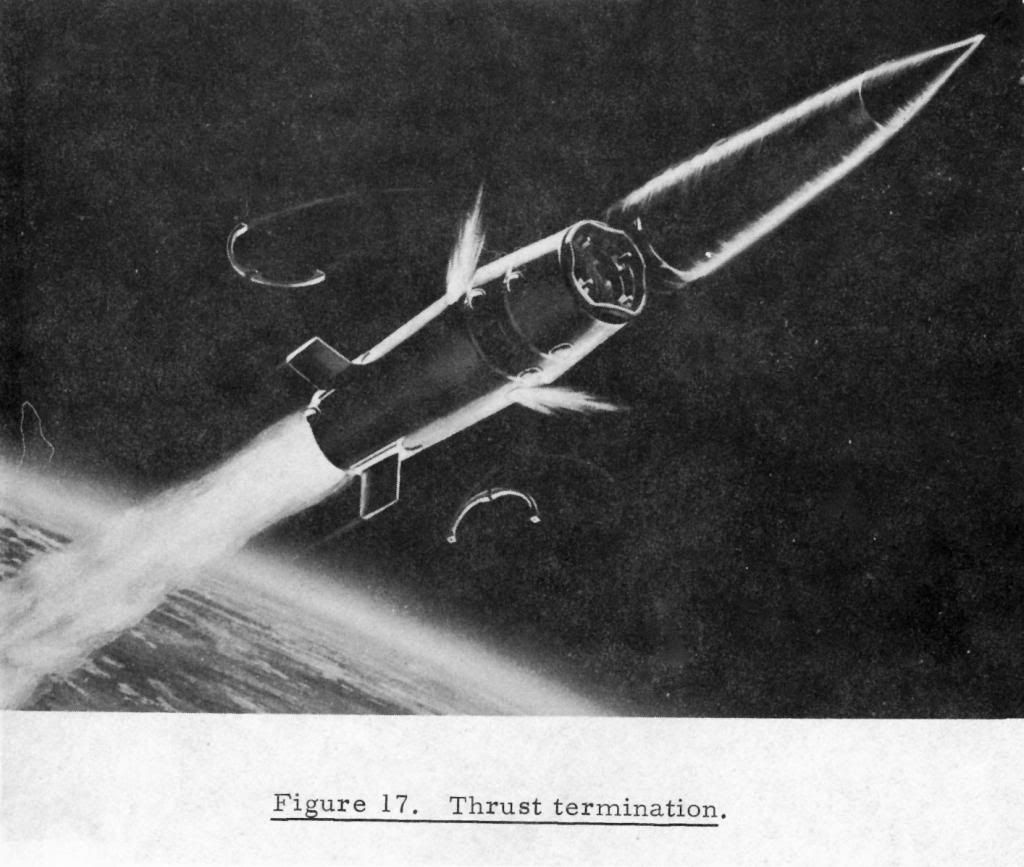

(5) Propulsion–solid propellant, two-stage.

( 6) Guidance - - inertial.

(7) Warhead- -nuclear.

b. Tactical characteristics of the Pershing are as follows:

(1) The system is mounted on tracked vehicles.

(2) All elements are transportable by phase II aircraft.

(3) All elements necessary for firing are transportable by helicopter.

(4) The guidance system and firing system are immune to electronic countermeasures.

(5) The communication system allows separation up to 160 kilometers between the battery and the battalion headquarters.

GROUND SUPPORT EQUIPMENT

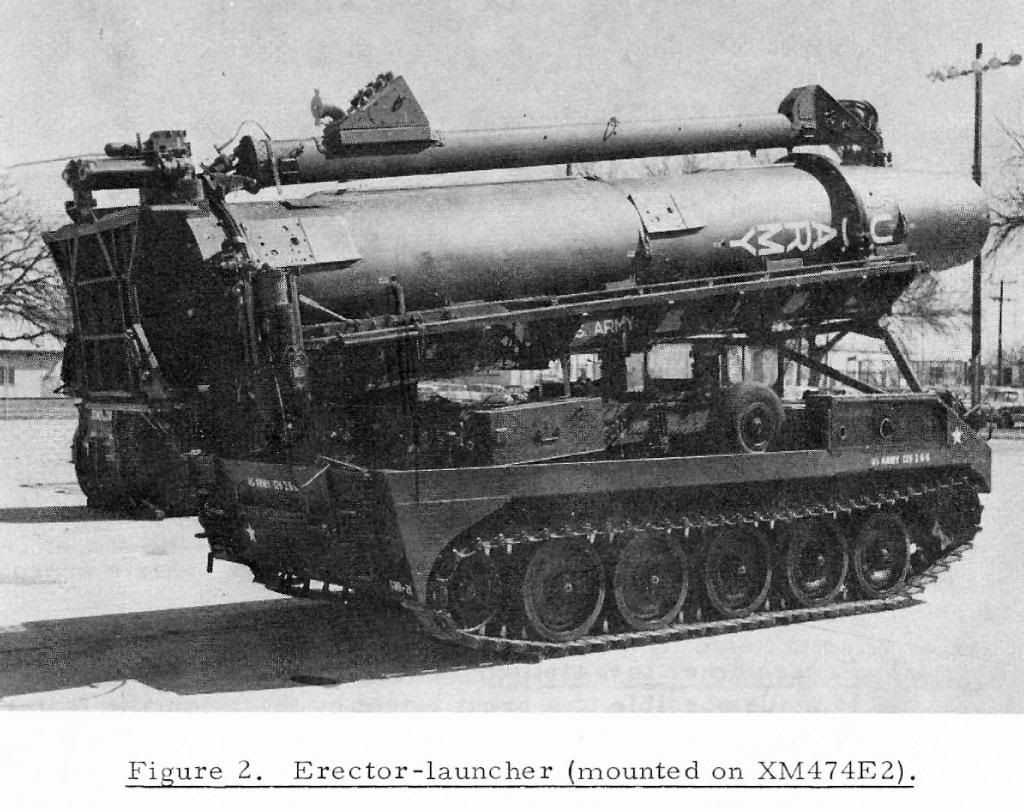

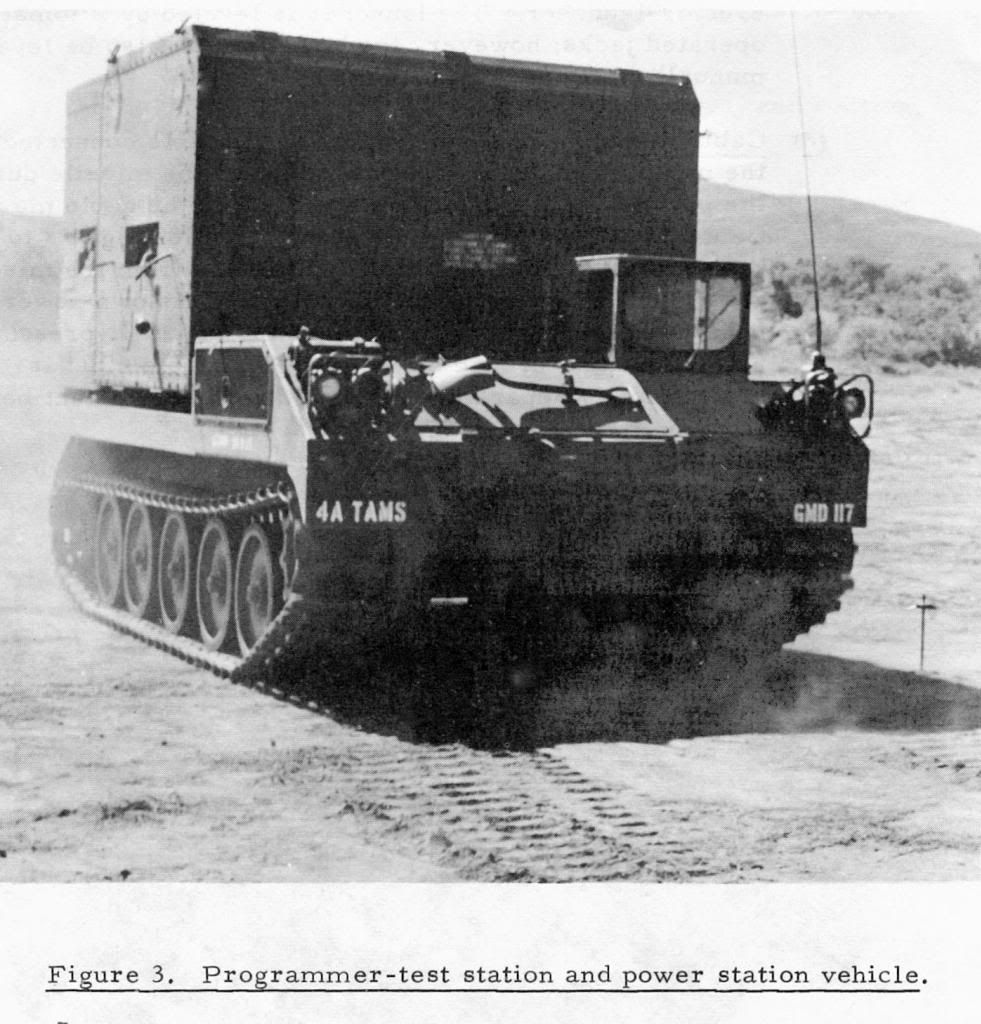

The Pershing system is designed to achieve minimum reaction time with maximum mobility and reliability. Mobility is provided the firing battery by mounting all Pershing-peculiar equipment, including Communication equipment, on tracked vehicles, designated the XM474E2 missile equipment carrier. The XM474E2 is a modification of the Mll3 armored personnel carrier and is specifically designed to transport the Pershing system. Mounting kits permit interchange of any of the four

Pershing loads from vehicle to vehicle without modification of the basic vehicle structure. The XM474E2 is lightweight and unarmored. It is capable of speeds up to 35 miles per hour and has a cruising range of 320 kilometers. It can travel in swamps and streams to a depth of 1. 3 meters and climb 60 percent inclines. It is powered by a 215-horsepower, V8 engine.

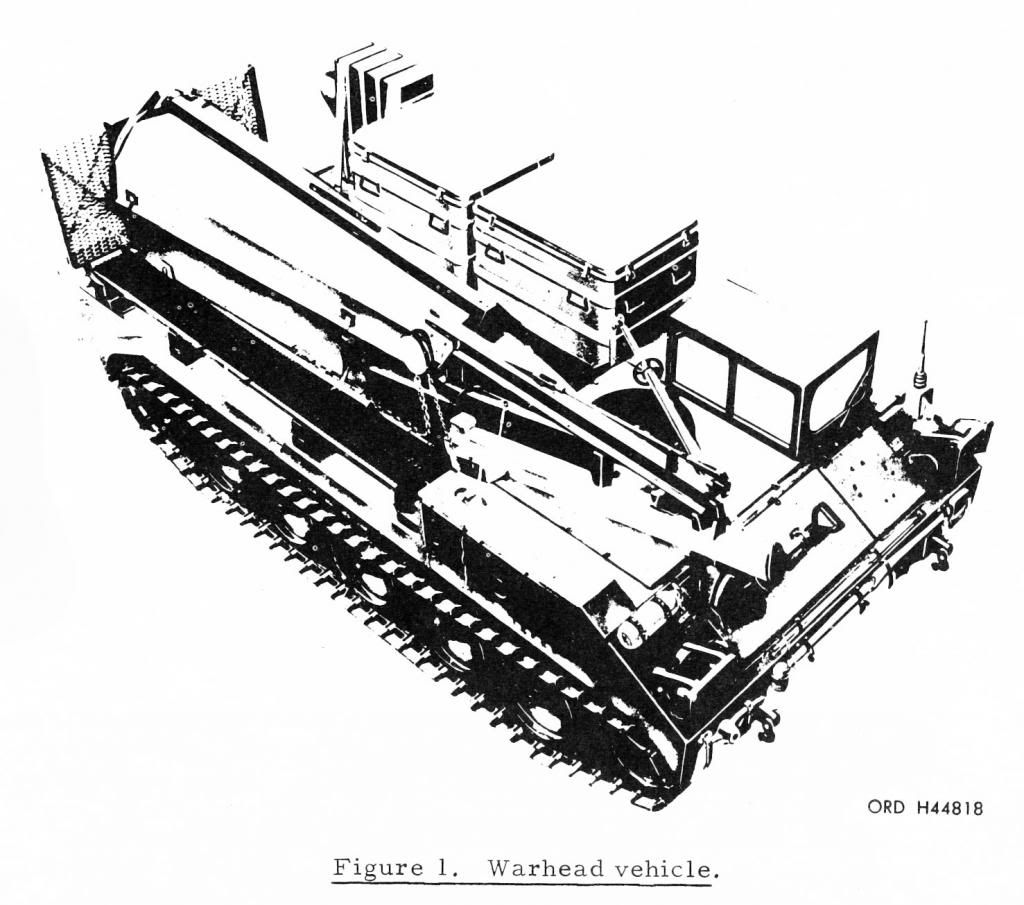

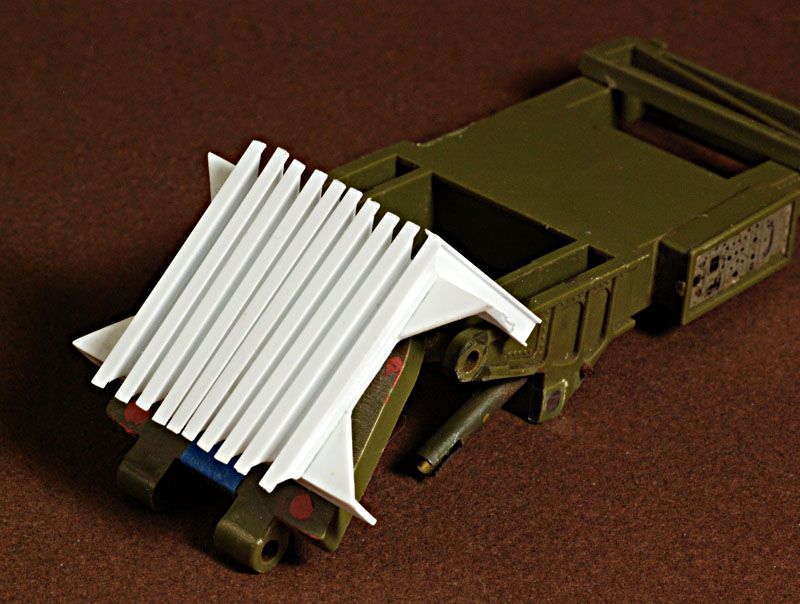

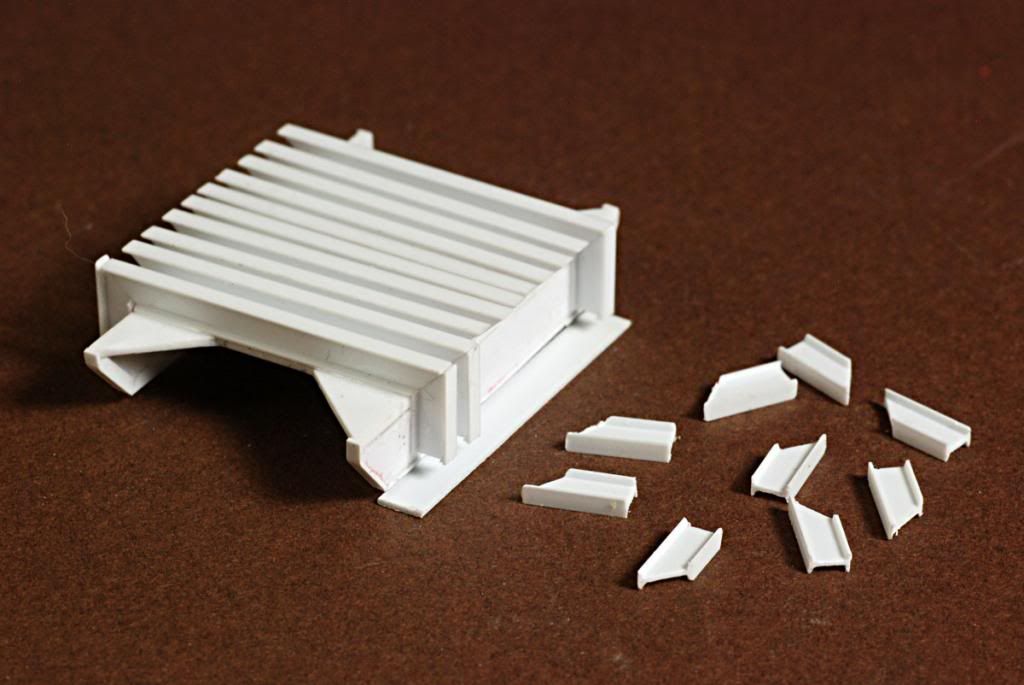

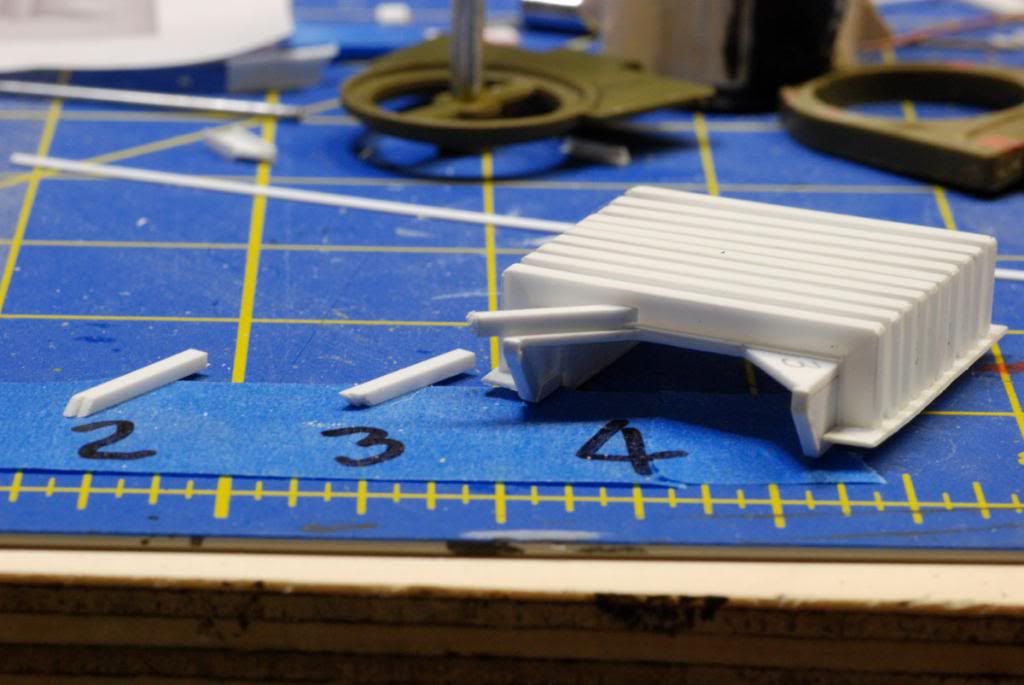

a. Warhead Vehicle. One XM474E2 carries the warhead section, two chests containing the azimuth laying equipment, and a container carrying the missile air fins. This vehicle also mounts a collapsible davit assembly which is used to mate the warhead section to the missile at the firing position.