This whole project is my first ever kitbash (using 2 c-17 kits), and also the very first replica prop my new company is making. This one will be a one-off and will probably stay with me (unless someone makes a really nice offer), but I plan on building another 3 or 4 that will be ‘in-flight’ like the one on the desk in the show.

After countless hours researching and pouring over the screen caps, I got started…

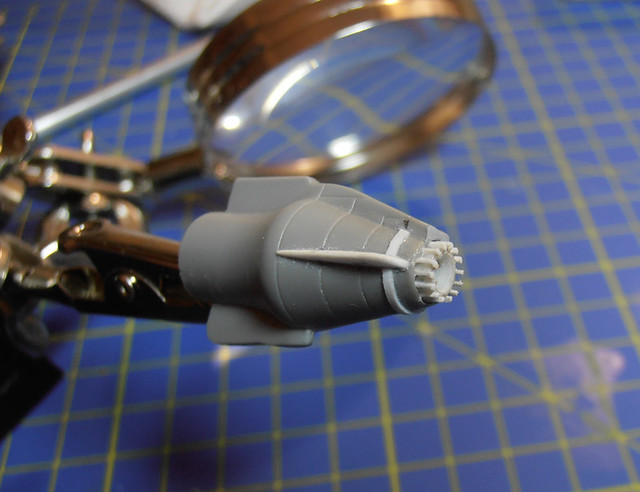

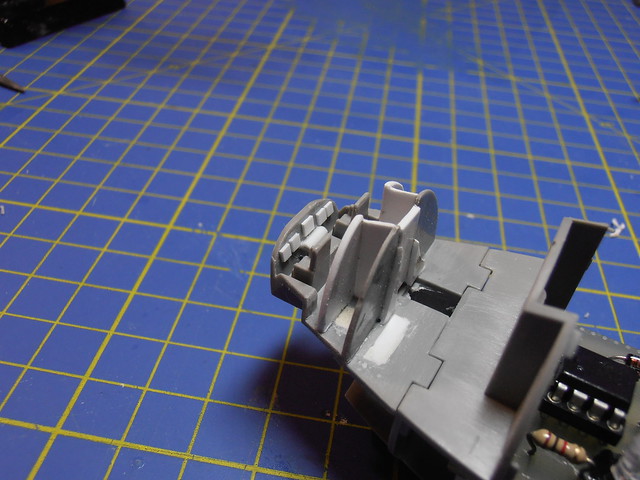

First, I started with the engines. The kit supplied were just all wrong. 18 additional pieces of styrene per engine were added to make it look right.

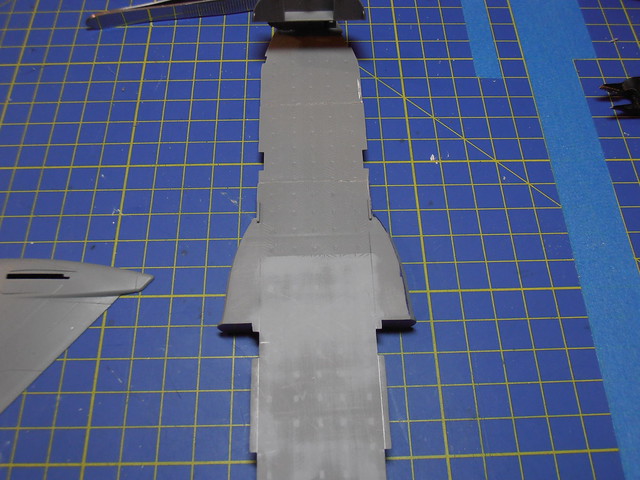

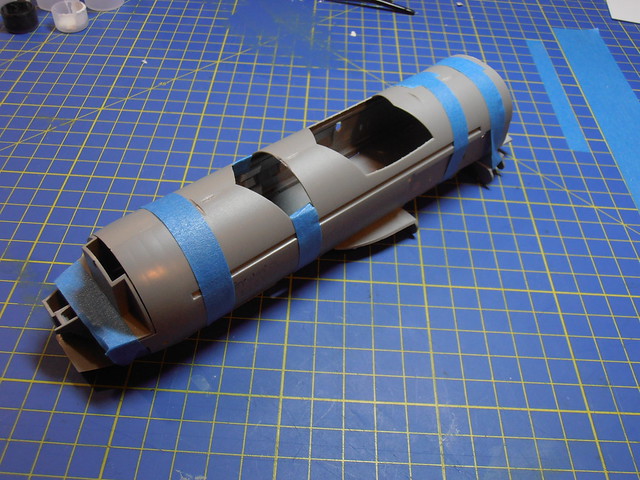

I had to cut and stretch not only the airframe but also the cargo area… Also had to modify the sponson on right side to match the opposite side. The screen aircraft has equal length sponsons.

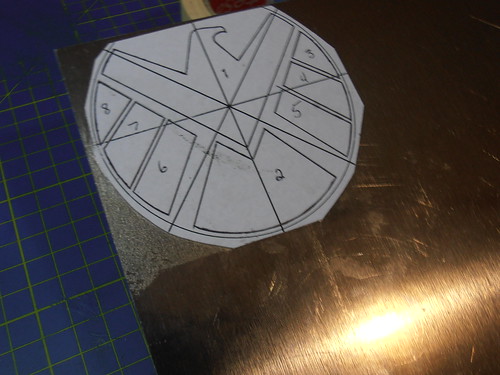

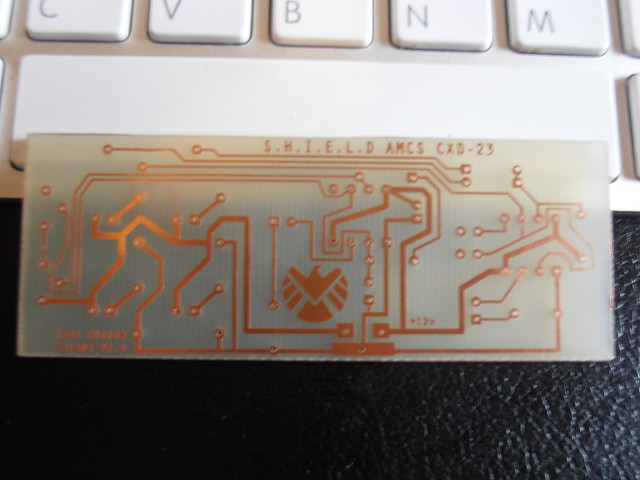

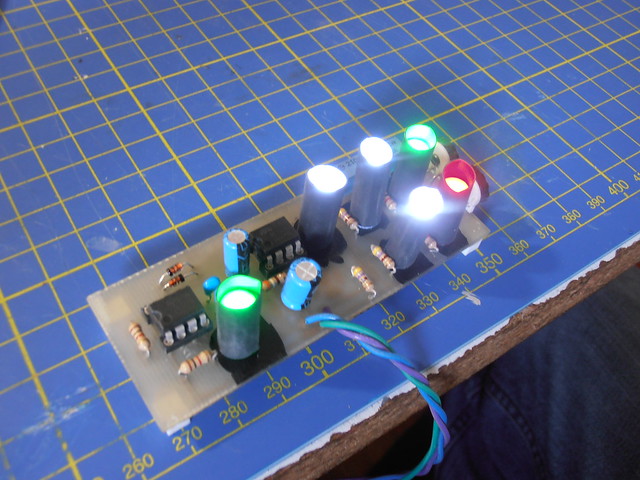

She’s getting fiber optic lights, so I needed to fabricate a PCB for the LED’s… the board has 1 green LED with a dimmer, 1 strobe, 2 bright white leds and the 2 for the nav lights. It’s all activated by a touch-sensitive on switch with a timer that’s going to be in the shape of the SHIELD logo on the base. Never did anything like this before.

managed to get a pic with the strobe lit up.

12v power comes via the landing gear. Once set “on the ground” the power wires can’t be seen.

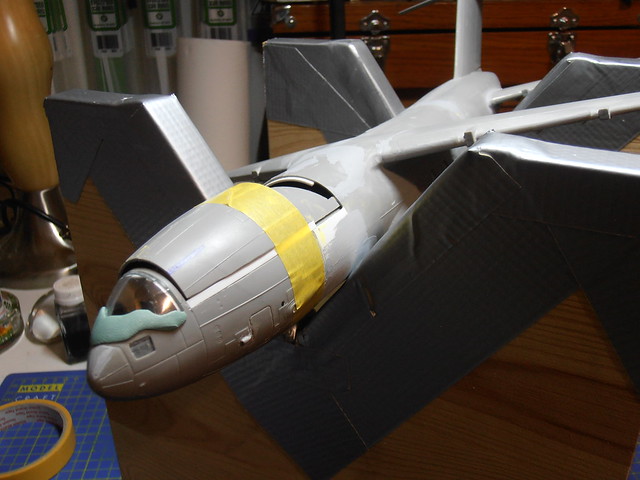

The rear wings on the screen aircraft aren’t as far back as they’re shown on the blueprint that I had found. In fact, the ‘blueprint’ is all wrong when compared to the screen aircraft. After some cutting and lots of sanding, they hug the lines of the fuselage nicely. Almost no filler was used in the joint after gluing them on.

cockpit details… some ‘screens’ added and the throttle hump in the center. Seats were removed and closets put up. The cockpit door was closed up and now hold the fiber optics.

Just before closing up the cargo area

Modification of the right side sponson to match the other side… Used the recessed panel lines as guides.

Quick dry-fit to see how it is on the 40cm2 x 1cm thick Black Granite tile that will be part of the base. The base will have a 25mm thick plywood backing and be surrounded by either mahogany, walnut or red oak moldings.

One of the last modifications was the addition of the hump. I’ve cut the section away at the panel line and kept the arch for the cockpit glass in place so things get put back where they’re supposed to be.

First attempt at getting the height, I glued 2mm styrene strip but it was too much and made it look strange.

The angle was all wrong, so I removed the 2mm and put in 1.4 mm strip. Cut a couple of reliefs into the top and heated them until I got it where I wanted. Looks much nicer. Ugly, but nicer.

Next on the hump, was the skylight for Coulson’s office. This little thing took me all day, literally 8-fun-filled-exiplative-laden hours to complete. I had only one shot to get it right and kept checking and rechecking against the screen caps I had because failure at this point would be very bad (no spare fuselage to cut up). I went very slow when cutting too. That square hole by the wing is an access point so I can drill into the LED and attach the Fiber Optics for the office.

all cut out… Those little diamond files are awesome for stuff like this.

Since it’s going to get ‘frosted glass’ it needs something to keep it in place. Single piece of styrene added to the underside and carefully filed away by hand until it was just right.

Made a box to hide the components inside and also to reflect the fiber optics better. 3 strands of fiber optics are in there and give a nice glow to it.

One of the 3 fiber optic strands in the office.

Now that the office is done and in place, top section attached, time to close it up.

Since I was using a single piece of styrene to close it up, the area of the hump just aft of the office is too flat. Millitput to the rescue!! Those relief cuts and and gaps were filled with styrene strip then smoothed over.

Still needs a bit of work, but it’s looking good.

And let’s not forget to plug it in as see it all lit up. In all, there are 22 individual points of light inside the aircraft. The cockpit also has Green light, but can’t be seen too well yet. Once the clear plastic is painted, it’ll show up better.

So that’s where she’s at now… still scribing & replacing sanded off detail before the first full coat of primer.

Thanks for looking ![]()