Making a punch and die set is really quite easy - and it’s really inexpensive - you just have to have access to a few tools to make one.

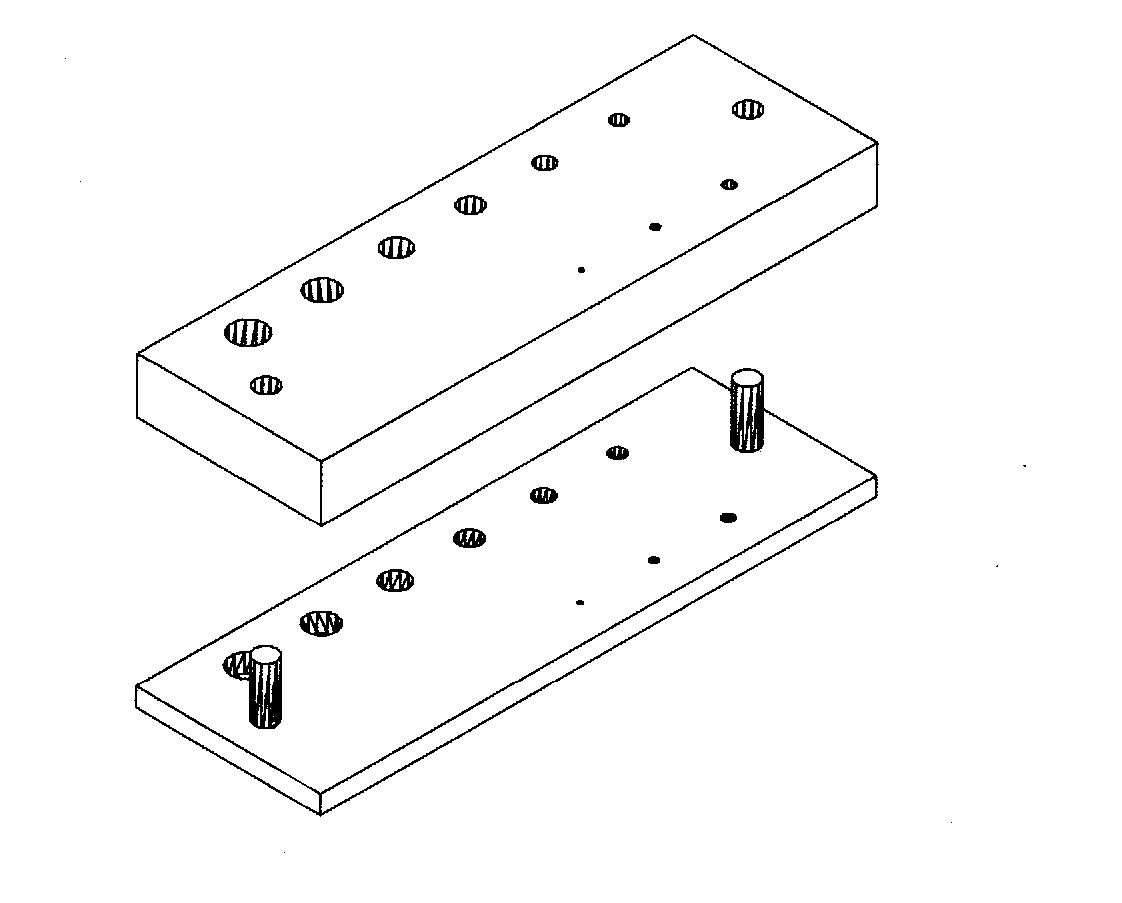

Below is a drawing of one I made a while ago…

Now - imagine the top piece is acrylic about an inch thick…the bottom piece is steel or aluminum about a quarter of an inch thick.

Cut both pieces so that they’re the same overall size, clamp them together, and using a drill press, drill two holes in either extreme end right through both pieces. These holes are for steel locating dowels that you should glue or solder into the metal base plate. Make sure the dowels you use are a snug fit in the holes that you drill - just match the drill size with the dowel size.

Once these dowels are stuck fast to the base (making sure the top acrylic block slides on and off easily), and using the drill press to keep all the holes perfectly square to the base, drill a number of holes along the side…from larger to smaller - whatever sizes you need.

Make sure that the drill is set on its slowest rpm setting and work slowly - use lots of 3-in-1 oil or a suitable coolant to help keep the drill tip and flutes cool so you don’t heat and melt the acrylic.

Once you have the holes drilled, hit the back end of the drills you just used (to make all those different sized holes) with a fine grinding wheel on a bench grinder to make the ends as perfectly flat as you can get them - with nice sharp edges. These edges, along with the sharp edges on the metal base plate you just drilled, are the effective “cutting edges” - cuz what you’re doing is “shearing” the plastic or paper or whatever…by placing the original between the metal and the acrylic, placing the back of the drill into the right hole, then hitting the drill point with a weight…I use either a plastic hammer or a brass hammer…neither one will damage the drill tip.

The extra thick acrylic top gives more support for the drill and acts as a “guide” to ensure that the drill doesn’t move offline or at a slight angle - the more carefully you make this tool, the longer it’ll last and the sharper the cuts you’ll get.

I’ve used a metric drill set to make my punch and die set - they come in 1/2 mm steps from 0.5mm to 13mm…lots of variety there and a size for any application I might find.

If you have any questions, just email me at the link below - I’d be happy to give you any help you might need.

Good info. I saw a buildup of something similar to this on Armorama a couple of weeks ago, but the author mentioned something about using rivets as the ‘punch’ components of the punch and die set. Not too clear on what he meant, and I think your set is a lot more sturdy.

Hey I remember you.

Thanks! LeeTree Ive been planing on making one of them but wasnt sure what to use for the punch.

Great idea. Thanks for passing it on. Do you hold the patent on it?[;)]

Hello.

Good idea and method, do you have any ideas on how to make the hexagonal ones, or go directly to the britts or Italian tools and buy t hem?

J3gm

J3gm,

You CAN make square or hex holes in this type of punch and die set - but it’s really expensive - to cut the square or hex holes you need a special tool called a broach, and you’d need a number of them to cut holes of differing sizes. Then you’d need solid hex or square stock to make the punch.

I think it would be cheaper to buy a set already made.

LeeTree

I’ve been around a few stores and companies, to see if they could build them, the rough answer is yes but it is very expensive, this shops vary from normal milling and turning to laser ones. So I think I´ll stick with the Historex ones. Comparing from the picture that you can see at the site of : http://www.steelmodels.com/prodotti/Armour.htm , it looks neater than Historex, but it is like comparing a pin up poster and the wife you have at home (I´ll stick to what already have), but the idea of making my own set, is still around.

Greetings

J3gm

Hi.Lee.

I’ve found a way to make various sized bolts using the smaller sized allen keys you can push them out with minimun force from thin plasticard or fastfood aluminum trays all you need is some dense rubber to use to knock them out onto I found that an old ice hockey puck works great.

Happy Modelling.

Regards panzermann.

[tup][tup][tup][tup]…

well presented and quite eloquent…as usual

[tup][tup][tup] thank you for sharing!!!

Yes - great idea to make a cheap facsimile of the over-priced Waldron sets. Where DO they get those prices from?

I’ve got an engineering friend working on it as we speak [:)]

I haven’t tried this, but had this thought the other day. You might be able to use telescoping rods like those ofered by K&N. The are made of brass aluminum and steel and come in various shapes. I have also used a leather punch for larger discs.