I had that same problem years ago when I was preparing to airbrush my model. To help others deal with this problem, I put together this short “How-To.” I learned this method many moons ago, inspired by modelers from the pages of FSM. I’ll sow you how I make painting handles shaped from wire hangers to airbrush my aircraft hands free! Hey, maybe this should be a sticky in “Tips & Techniques” here. (Hint, hint- Jeff Herne)[;)] Anyway, her we go!

The first thing I do is find a regular wire-type garment hanger. Wire hangers are ideal becuase they bend easily with pliers and you can form custom shapes to accomodate various models for airbrushing.

Next, I use priers to shape the hanger into any shape I need. Also, for creating your handle, you may want to use wire cutters, but I simply bend the wire repeatedly to easily snap off a section where desired. Sometimes I just bend-off the hook portion of the hanger and use the spiraled stem as the holding prong to be inserted into a wood block to hold the model while it drys. In the this photo, I did just that. This one was made to accomadate twin-enigine jets, such as this 1/72nd scale F/A-18A. I wrapped masking tape around the bottom portion of the shaped hanger to form a stiff handle. The remaining long prongs can be inserted inside the rear of the model. Make sure these prongs are long enough so that while you twist and rotate your model during painting they don’t easily slip out!

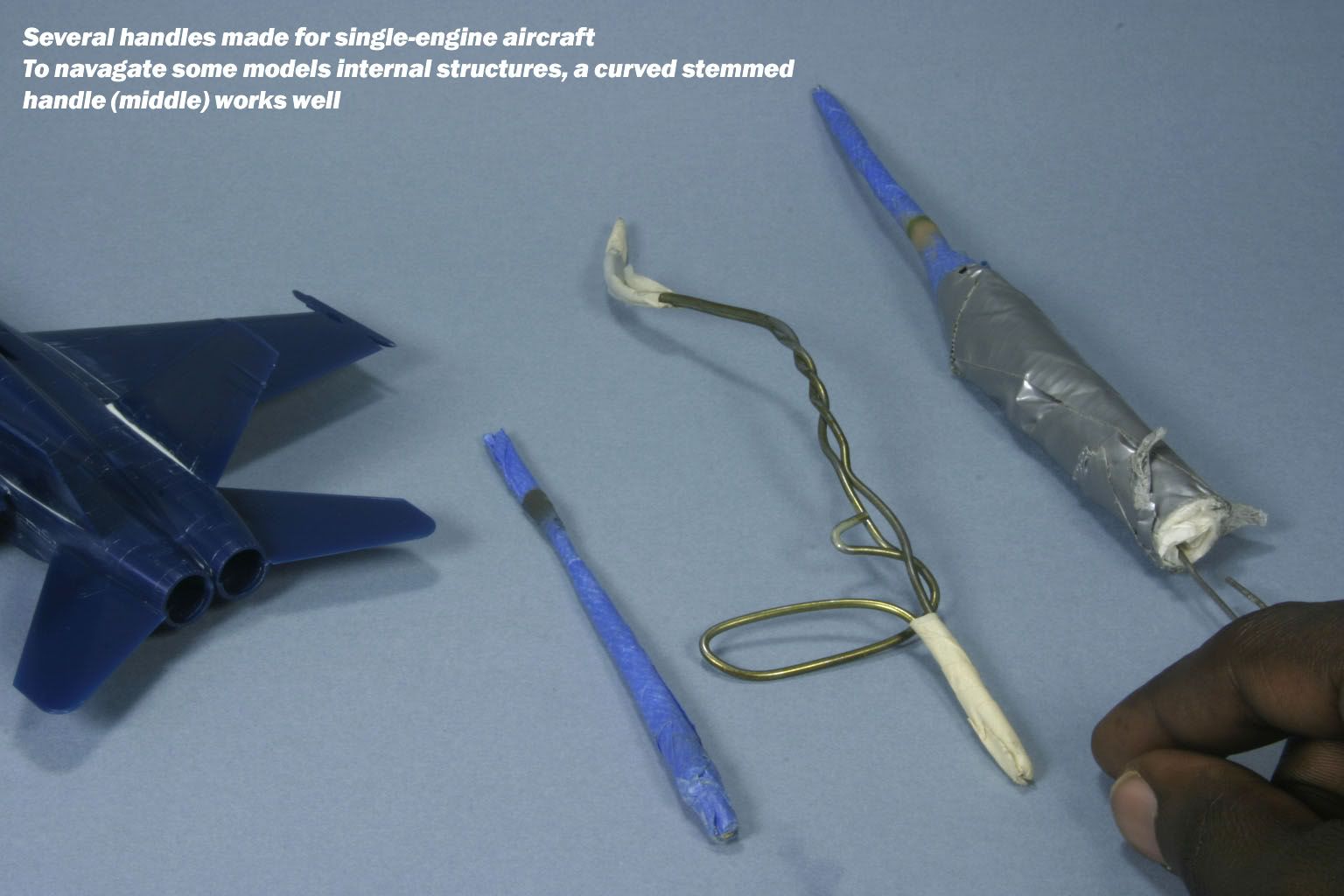

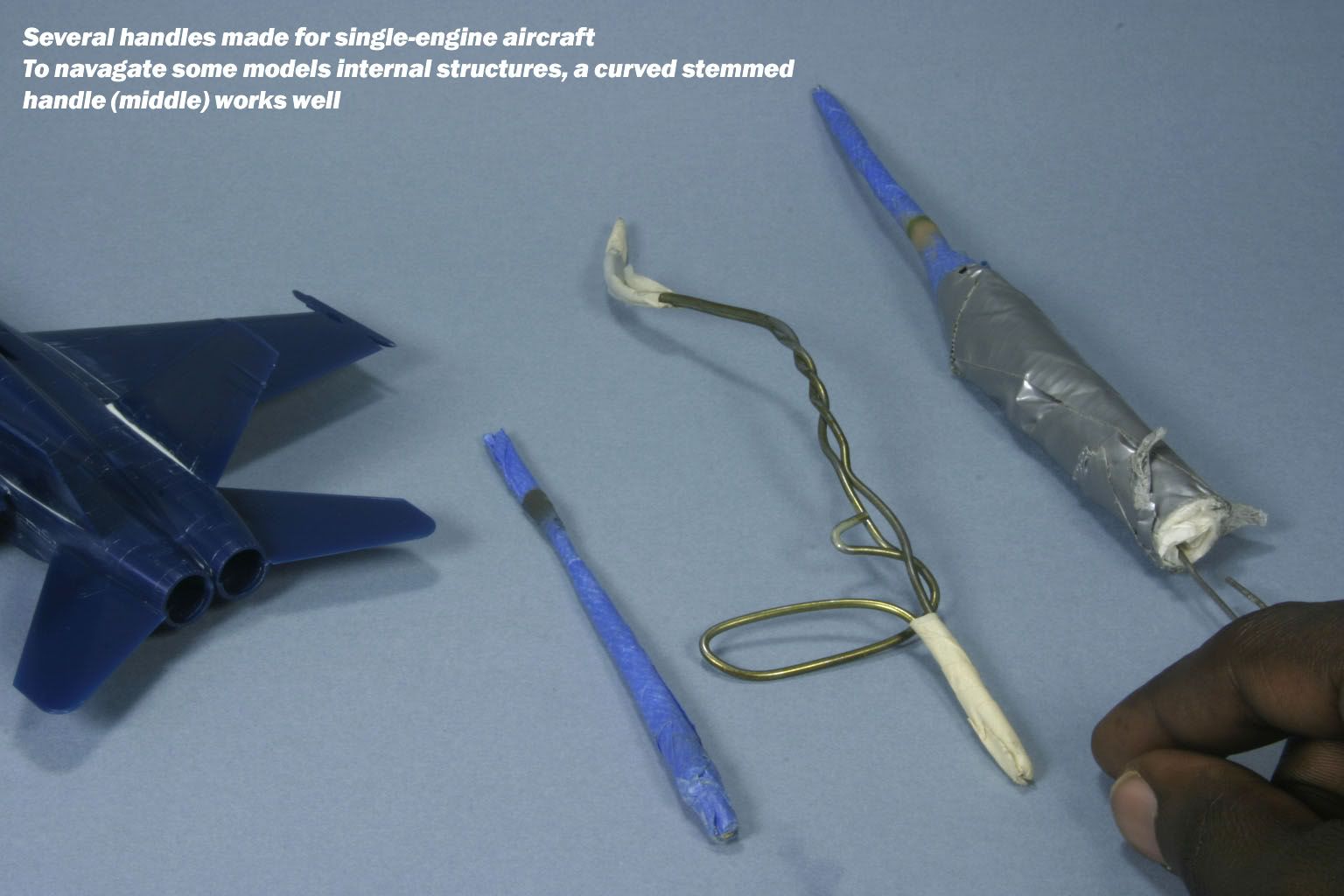

The same goes for single engine jets and WWII aircraft as well, just use your imagination, think about how you want to hold the model comfortably and bend the hanger to shape. These are some other handles I made for my single-engine jets. After bending the hanger and fashioning the handle, you need to test fit the stem into the model and make any adjustments. Realize that some models have very cramped interior spaces, you may need to modify the handle’s rod accordingly, so it can fit in and around intake trunking, bulkheads, etc. Also, I routinely have to wrap masking tape on the stem portion of the handle so it will fit the available openings snuggly. You don’t want the model flopping around as you airbrush!

When you’re satisfied with your custom shaped handle, insert it into the model. Also be proactive and take a look at your other kits in the stash. Does your handles need to have long prongs for 1/48 scale, or relatively short ones to fit the spinner holes for your WWII warbirds? This two-prong handle will accomadate the majority of my 1/72nd scale twin engine F-15’s, F-14s, etc.

“Hey Ma, look- no hands!” Here you can see how the handle holds the model for airbrushing. I can turn, rotate, and angle the model hands free for airbrushing.

What do you do after painting to let the model dry you ask? When I make my handles, I leave a 2in section of the spiral section of hanger to serve as a post. For this one, I shaped a loop with pliers on the rear of the handle so I can insert the handle into a drilled-out hole in a block of wood. The tiny holes you see in the wood block are to accomodate toothpick handles!

The block is mounted on a shelf just inside my spray booth. The handle serves double duty. It holds the model during painting and also to hold it securely as a paint stand until the paint dries.

Well, there you have it, handles! That should alleviate some stress as you airbrush that glossy paint scheme or intricate camo job, without fear of handling the model. Be creative, you can make better ones fashioned from wood dowels, aluminum & brass rods. Happy modeling!