I’ll take the liberty of sticking an oar in here. I don’t disagree with any of the earlier posts, but I do have a few other observations on the general subject of mounting and displaying ship models.

First, if you want to put your model on a baseboard, there’s no need (unless money is a major problem) to be content with the sort of wood you’re going to find at a place like Home Depot. (That will almost certainly be pine. There’s nothing wrong with pine, but few people would call it the classiest-looking of woods.) The Lowe’s store in my neighborhood also sells very nice pieces of poplar and red oak. Stay away from poplar unless you’re going to paint it. (It turns green as it ages.) Lots of people like oak for baseboards. (It’s not my favorite, because of its coarse grain), but it probably would look very nice as a baseboard for a relatively large model.) Since you’re only going to be buying a small piece of it, the difference in price between oak and pine won’t amount to much.

My own personal favorites are cherry, maple, and walnut. There may be a lumber yard in your neighborhood that stocks them. If not, a good source is Woodcraft ( www.woodcraft.com ); I’m sure there are plenty of other good online sources. It’s hard to beat the look of a cherry, maple, or walnut baseboard.

The last model I mounted on a baseboard was the Revell Viking ship. I drove to the Woodcraft store in Raleigh (an hour-and-a-half drive), and rummaged around its lumber racks until I found a piece of spalted birdseye maple that just screamed “Viking ship” at me. It cost less than $10.00. I sawed it to length, routed an edge on it, and finished it with Watco Danish oil and Watco satin polyurethane varnish. I’m delighted with the results. So is my wife, who is, if anything, more sensitive to the aesthetic aspects of such things than I am.

If you have (or a friend has) a router, you should consider putting a decorative edge on the baseboard. My favorite tool for the purpose is a little Ryobi “trim router” that I bought at Home Depot for less than $100. My favorite bits for this purpose are a set of “miniature” ones sold by the good folks at Lee Valley: http://www.leevalley.com/US/Wood/page.aspx?p=30227&cat=1,46168,69435,46179&ap=1 . You don’t need much woodworking experience to get beautiful results with these little guys. (Warning: once you get a router in your hands you’re likely to get hooked on it. A router opens up all sorts of modeling opportunities - and even more beyond model building.)

You can also buy very nice ready-made baseboards. A couple of sources: http://www.bluejacketinc.com/baseboards.htm and http://www.modelexpo-online.com/search.asp?SKW=cat1_MX%20Board . Bluejacket’s are cherry; ModelExpo doesn’t identify its wood species. I’d want to find out about that before I ordered one of those boards.

Bluejacket also offers a nice range of brass mounting pedestals: http://www.bluejacketinc.com/pedestals.htm . The keel slots obviously will need removing for a modern warship model, but that’s no great trick.

No rule says all the pedestals have to be on the ship’s centerline. I’ve seen lots of fine warship models with pedestals under the bilges, as well as the keel. To my eye, that actually looks better under a big, broad hull than pedestals just under the keel.

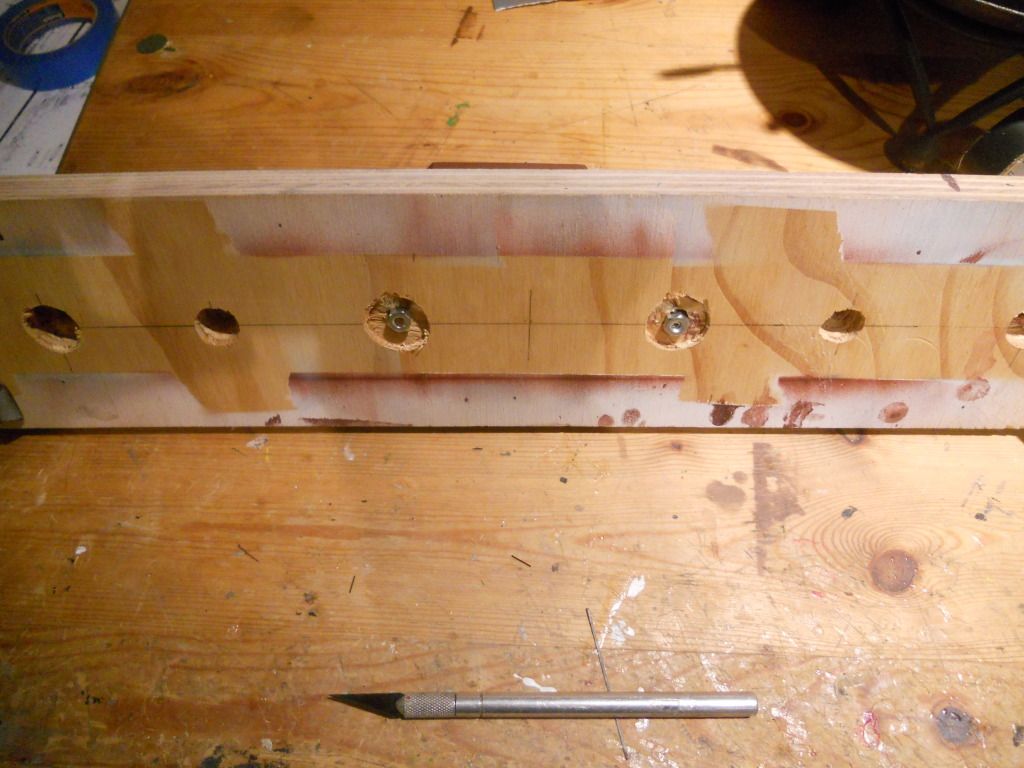

The best time to drill holes in the hull, obviously, is before the decks are installed. My favorite technique for a plastic hull is to glue (really glue) two or three steel nuts inside the hull, and use bolts for the fasteners. (Whether two or three depends on the size of the ship - and the builder’s personal taste.)

If I were working on a good-sized twentieth-century warship model, and hadn’t drilled the mounting holes in advance, I’d be strongly inclined to go the “keel blocks” route. As several pictures in this thread have demonstrated, that’s a nice, attractive way to do it. I’d be inclined to make the “keel blocks” out of a nice harwood that contrasts in color with the baseboard. (Maybe walnut keel blocks on an oak baseboard - or maple blocks on a walnut baseboard. Maple and walnut go beautifully together.) You can also paint the keel blocks black. (There’s a good application for poplar - which Lowe’s sells in square strips.)

Making holes in the bottom of a plastic hull doesn’t need to be a big deal (though it will be considerably bigger if the model is almost done). A drill bit will do the trick. So will an Xacto knife. Mark the location and diameter of the hole and spin the knife blade around for a minute or two. The hole may not be perfectly round, but (depending on the mounting method) that may not matter. I like the idea of the keyhole-shaped hole that was mentioned earlier.

The biggest, most important consideration in displaying a model: either get or make a case (glass or plexiglas) for it, or keep it inside some sort of cabinet. (My wife and I bought a curio cabinet at a local furniture store for about $200. It holds most of my models, and looks nice in the dining room.) If you decide you don’t like the mounting system on your model, you can change it. But if you leave your model exposed to dust, cats, and kids, you’ll regret it - pretty quickly.

Hope this helps a little - and maybe provides a basis for some thought. Good luck.