A new project has begun. I had been planning on building a Chinook since Model Expo 2017, I even had a couple of 1/48 kits in the stash that I was going mix and match the rotors to build a correct AAAvn version, and then just before Expo this year, and I decided that Army Choppers looked so much better in 1/35 and they would compliment the 1/35 Armour I have so much better, so I sold them all up at the Swap and Sell and bought a 1/35 Trumpeter Chinook. Today with the completion of the two Meteors and after clearing of the bench, I got to work.

I’ll be using the Big Ed PE set which comes with masks, interior and exterior details, instrument panels and PE seats for in the cargo area. As I missed out on getting a set of the 1/35 Ronin decals for the Chinook, I’ll be going with the Hawkeye models decals and Werner Wings stencils.

After reading through the instructions a few times, taking notes and marking up where photo etch enhancements will be required, I got to work. I started with trimming and assembling the front console. It was pretty straightforward. Test fitting as I go.

The internal bulkheads were next. They went together pretty well and look pretty good.

A dry fit to see how the components look together. This is going to be a big beast. Heaps will be seen through the big windscreen, so I have to get as many photos of I can of the cockpit so I can match it the best I can. The hunt is underway. Anyone who knows of any good walkarounds that can help me out, please do.

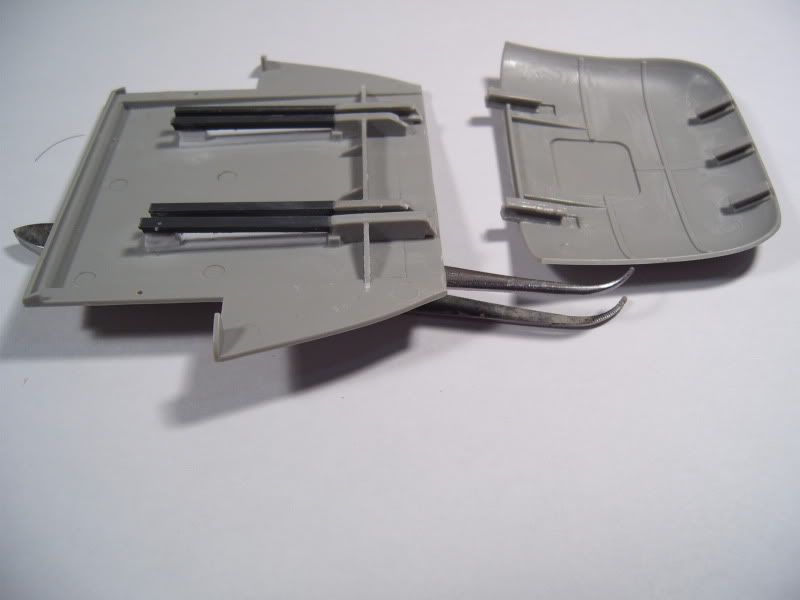

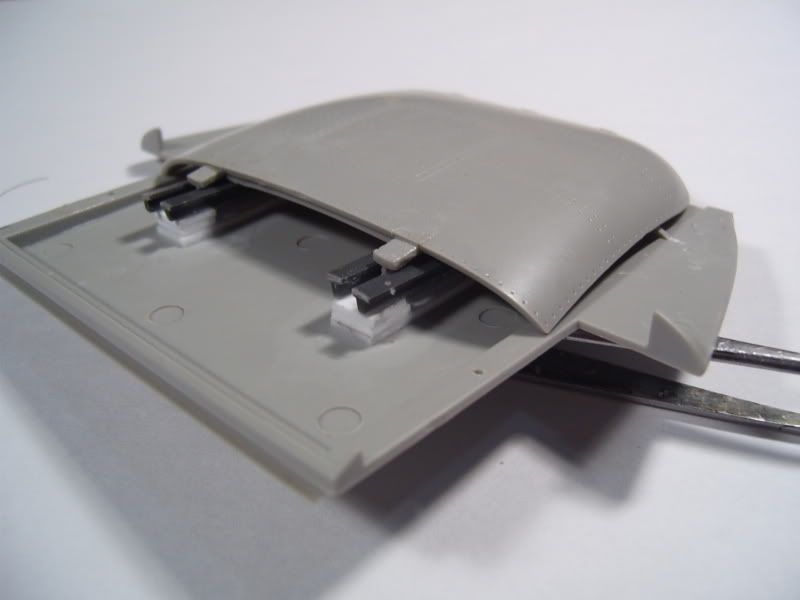

For the most part, injection marks have been minimal with them hiding in either easily cleaned up locations or hidden, but a few have me scratching my head on why. The first why is under the instrument panel combing. They’re deep too, so they will need to be filled. but the main issue to date has been on the shelves in the avionics bay. The sinkholes could easily have been hidden on the underside of the shelves, but no, they’re on the top and will need to be filled before the shelves can be painted, assembled and installed.

The colour call out and parts are pretty limited too, so again some photos of this area would be greatly appreciated.

That’s it for today. More tomorrow.