I’ve been through this from both sides. You have to take comments about cheap lathes and mills with a grain of salt and consider what you need / want from a lathe. I’m sure the comments about the quality are spot on.

I have seen people who have bought similar machines make positive comments about them because they had low expectations and those expectations were met by the machine they bought. Also lots of negative comments from people who had higher expectations that were not met.

You probably can do a lot of the things you describe by using a drill or dremel as a cobbled together lathe. I’ve made a few simple items that way.

Several years ago, I was becoming interested in getting a mini lathe. I initially looked at some like this one, maybe even a little better (my budget was $250-300). My needs were small and my expectations low. With more research I figured out these cheap ones probably weren’t going to make me happy for long.

Then I started looking at the “cheap” ($500-700) Chinese lathes. Once I made the jump from $200 to $500, my needs and expectations changed. Issues I was willing to accept at $200, I was less willing to accept when I was spending $500+.

At that point I was then looking at $800+, better quality chinese lathes, Taig and Sherline. With each jump in budget, my expectations grew. Each increase also led to more thoughtfulness on spending that much money (do I “need” it, will I actually use it, do I actually have he paience to learn to use it) and of course also more time setting aside the money to make the purchase. It seems like cars, pets and children all know when you have money burning a hole in your pocket. [:O]

Ultimately I did buy a Sherline, but it didn’t end there. I was initially going to get the smaller (and cheaper) lathe with the basic package. Then I started to look at the longer 17" lathe, because you never know… and if I’m spending $700, it would be dumb not to spend another $100 to get one I know is big enough.

Then it was the extras, out with the basic package and in with the ultra deluxe package because those package deals really are good deals, so the price climbed from $750 to $1300. Then there was the need for a grinder to sharpen the lathe tools, and of course I don’t want a crap grinder so another $200. The hand powered hack saw gets old quick, so another $150 for a chop saw…

Start to finish it took about 4 years to actually get the lathe. I’ve had it about a year, and it looks lonely so now I’m buying a mill to keep it company, with the various accessories I “need” I’m probably down another $1800.

So Grand total, I’ve probably spent $3500 and I’ve made some parts I probably could have bought for about $100…

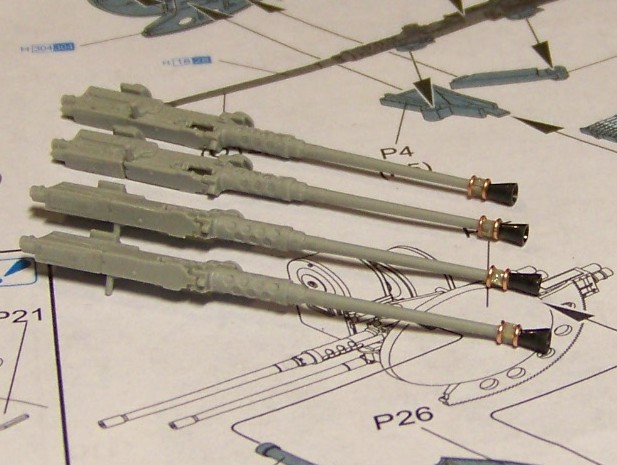

Still I’m pretty happy about it, I’ve acquirred a new hobby that fits in well with my existing hobby. Also at this rate in 35 years these tools might pay for themselves. I probably would have just bought more model kits for the stash anyway. [:P]