The Build - Undercarriage and Base Impressions

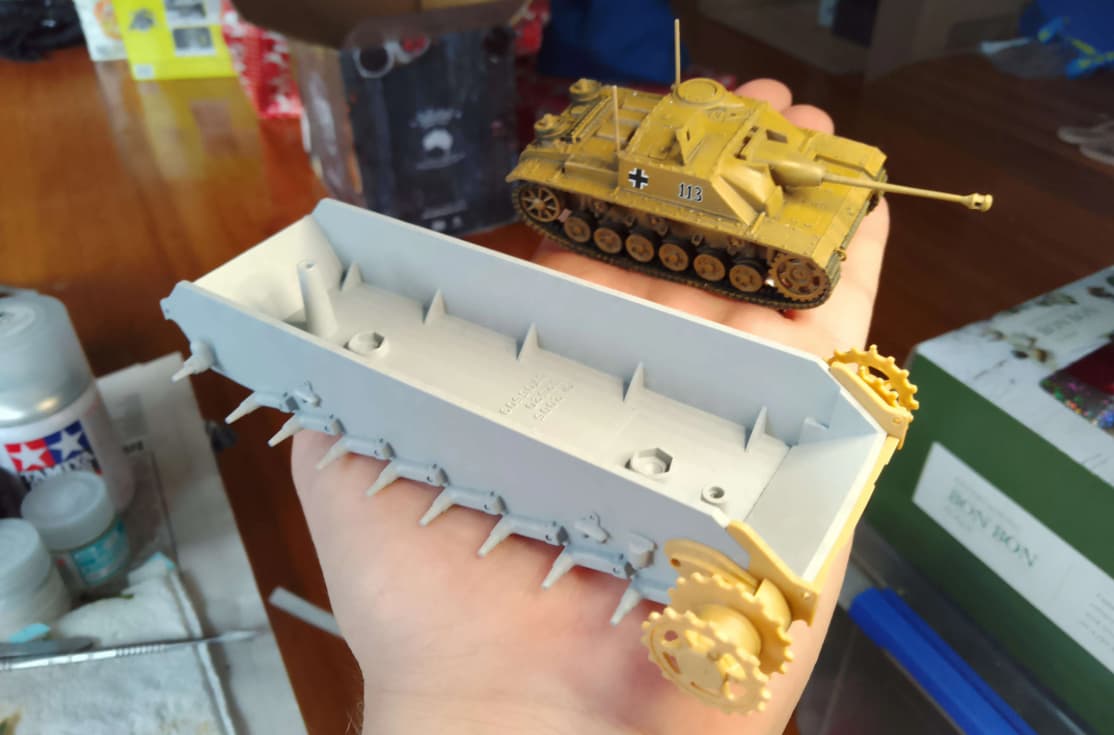

My first foray out of 1:72 scale modelling, I was inititally surprised at the sheer size difference between this 1:48 scale Panther and a 1:72 scale StuG III I’d built earlier. Granted Panther’s 45ton operating weight nearly doubled the 24t of StuG III, but it was still interesting to see. There is a 1:72 scale Panther in the stash, so we’ll get a side-by-side comparison eventually.

Unfortunately even though we’d only completed Step 1 of the instructions, we had already made a serious error…

The lower hull of this kit is made of die-cast metal, which really gives it some heft! I’m a little puzzled as to why they’d do this outside of a weight = implied quality equation, but my best guess is that it’s to improve the odds of everything fitting together

Road wheel assembly was measured in “Martinis per side” - Can it be said that alcoholics will use anything other than the metric system?

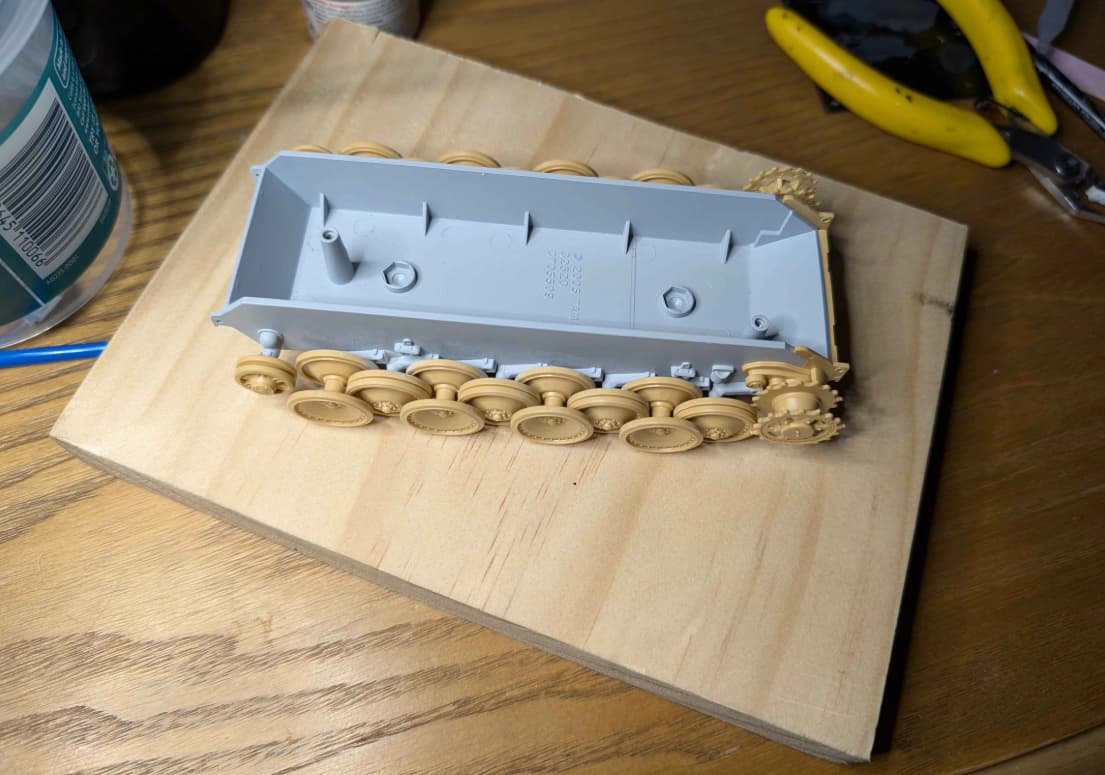

Many of you prefer to delay your undercarriage assembly until after a few steps into painting, and I guess I see why. But there’s no better way to get the spacing of track impressions on a display base right than using the actual model! Unfortunately making the impressions for my Cromwell IV’s display base after the model was finished gave me quite a nasty cleanup job that resulted in some loss of finish, athough thankfully not to any visible areas…

This time around, we’d resolved to build just enough model so that we could get the display base size and the track gauge correct, while still being able to use any means necessary to clean off the track parts afterwards

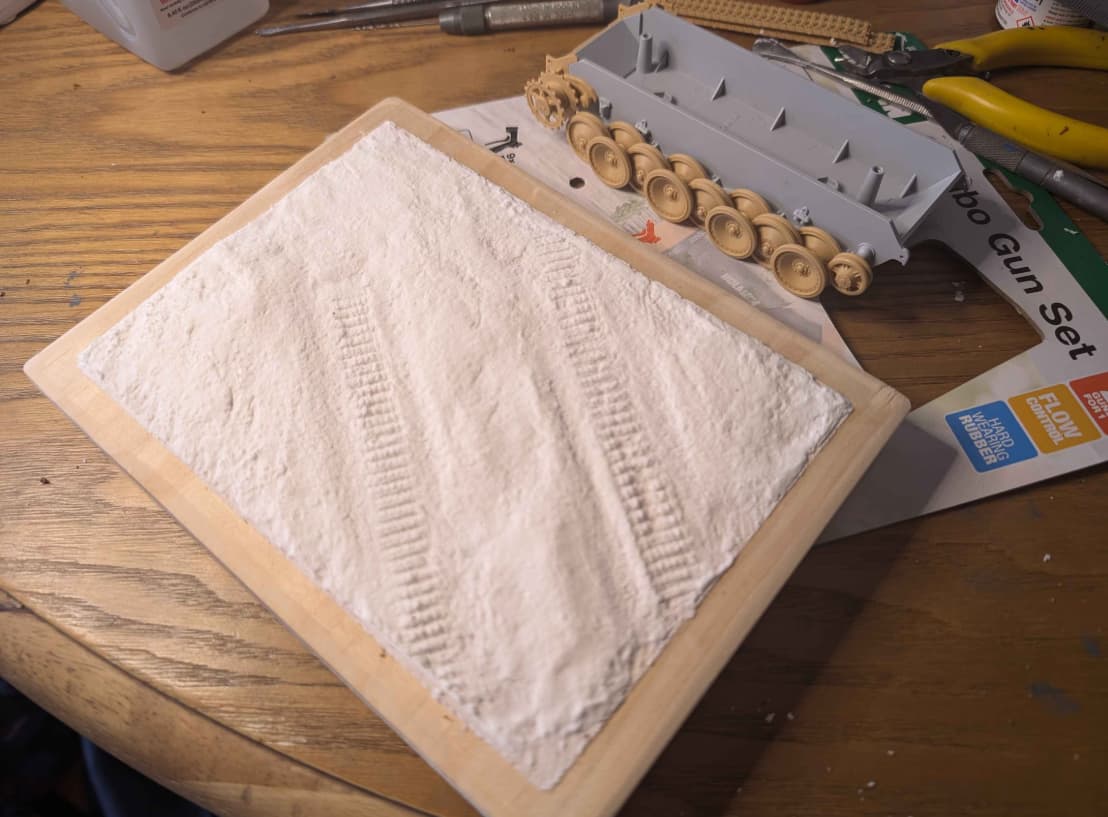

The board was sourced from Bunnings (like your Home Depot in the USA or HammerBarn in Bluey) and the shaping medium is SpakFilla. This is a quick-drying water-soluble plaster filler popular amongst landlords after their former-tenant Kyle decided their gyprock/drywall disagreed with their drug habit.

It’s not the easiest stuff to work with, and I can see why many pundits prefer an air-drying clay. Water needs to be added to get it to stick to anything other than Kyle’s hole in the wall, which in turn makes the product fluffy and mobile. Insufficient water means the product will clump and lift off the substrate while you’re trying to work it.

Dabbing with paper towel had the effect of draining and recompacting it into the shape we wanted, while leaving an earth-like surface. We could then make our impressions in the wet plaster using our model, leaving deep and geometrically correct impressions of the track.