I use a band saw quite a bit for scratchbuilding projects. I have a 105" Delta brand band saw out in my woodshop that I have been using for this purpose. Recently I thought it might be nice to have a smaller table top band saw just for my scratchbuilding. I decided on the 9" Delta Shopmaster and I was getting ready to order one from Micro-Mark who sells this saw for $170+ with S/H. I stopped into Lowe’s yesterday to see if they might carry it. Not only do they carry it but the price has been lowered to $87! They also had a brand called GMC for $77 that was the same size but has a laser aimer built into it. I stuck with the Delta which is a brand I trust.

Woody,

I’ve got the Delta 105" in my woodworking area too but always figured that it would be more problems than it was worth to use it with styrene. Apparently it isn’t but I do have some questions. What’s the best blade to use (width, TPI etc)? And do you have any problems with the styrene melting, not cutting and if so how to you overcome it?

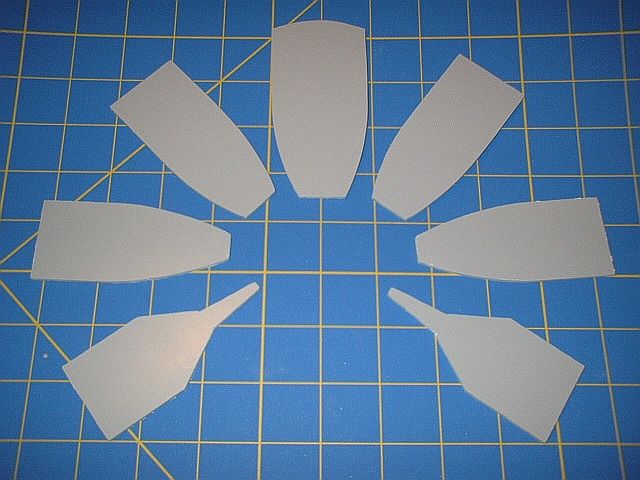

Hey Quincy, I’ve been using a 1/4 inch 6TPI Hook blade for my styrene sawing so far. I’m also planning on trying a 1/4 inch 6TPI Skip blade in the future. I was very suprised with the results I got when I first got the idea to use my band saw to save me some time. Below is a picture of pieces I’ve cut out using my big saw. They are raw in that they are as they came from the saw.

The cut is very clean without any melting. You can try to cut too fast and cause melting but if you let the saw do it’s work you won’t have that problem. My cuts look like they were cut with a laser.

If you have a big saw like that in your shop you must take woodworking seriously. What kind of wood projects do you do?

I don’t bother with any big band saw’s, as I am already really satisfied with my skil jigsaw with a 22tpi blade. people keep saying how a dremel is better for cutting metal, but with work like the one below, I doubt it (and I own a dremel too)

That looks great, I’m going to have to give it a try. As far as the wood working goes, really just getting started as we’ve moved 4 times in the past 20 years. No more moving, this house is ours (at least my Guard retirement checks makes the house payments) so I’ve started buying some decent equipment. Bought the bandsaw at an auction for 60 bucks (my wife has turned me into a cheap skate). Besides, with the proper blades, it works great for sheet metal work, which is set up for right now (been cutting some sheet metal for a friend who is building a homebuilt plane)

$60 bucks, wow! I gave almost $900 for my big Delta and it was on sale. Good find.[;)]

Wow, Woody. Neat find! I got the same bandsaw at Lowe’s and got the table saw with stand for the same price just before Christmas. I’ve been using both with small projects with wood around the house, and with styrene sheets for my modeling projects also. It’s a great find, and Lowe’s still had a few of each when I was there yesterday.

Hi, I’m new to this forum.

I have access to a bandsaw that has several speeds and need to cut some styrene models for a project. I gather that the saw blade should be a 1/4 inch 6TPI blade, what speed should the bandsaw be running at?

Thanks

Ed

Ed, As a rule of thumb with styrene, the quicker the blade the bigger the blade’s teeth need to be. A fast moving blade with small teeth doesn’t remove stock quick enough so you get lots of heat build up in the plastic.