Hi Guys, With the M4A3 105 out of the way I have started on my next project which will be an early initial production Tiger I. For the build I have dug out this old partially started Tiger I.

The tank hull is all constructed out of 1/4 inch thick plywood. and the turret is constructed out of layers of plywood and sheet metal. The tank’s hull and turret was started back in 2001, but never progressed passed the rough shape point that you see below and has been in storage ever since.

After about a week and a half of tweaking, altering, and refining the tank’s hull and turret is now ready for build up.

All of the tank’s wooden panels were thoroughly coated in Fiberglass resin and sanded to a smooth finish. As I mentioned in my past builds the fiberglass resin coating makes the model stronger, weatherproof, and transforms the wooden surface into plastic by removing wood grain.

On the original hull the upper and lower hull were designed to be two separate pieces, during the refinement the these two halves were mounted together creating one unit.

The lower hull tow shackle mounts were added. The final drive guard strip will be next.

On the tank’s turret The roof was added. More progress will be added to the turret as the build progresses.

I have built one of these hulls before in my last tiger I project so I have some of the detail parts on hand which will save time

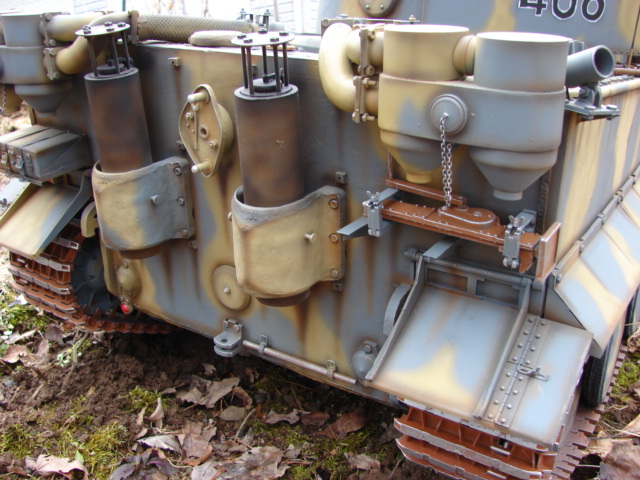

With the basic hull complete I will now be focusing on the tank’s lower hull detailing. These would include the final drive guards, final drives, angle brace, welds and ilder mounts. Once complete I will be working on the tank’s suspension.

I have a lot of special plans for this build as well as some very special detail parts in mind to produce. More progress and info to follow!