UPDATE 20

Hi Everybody!

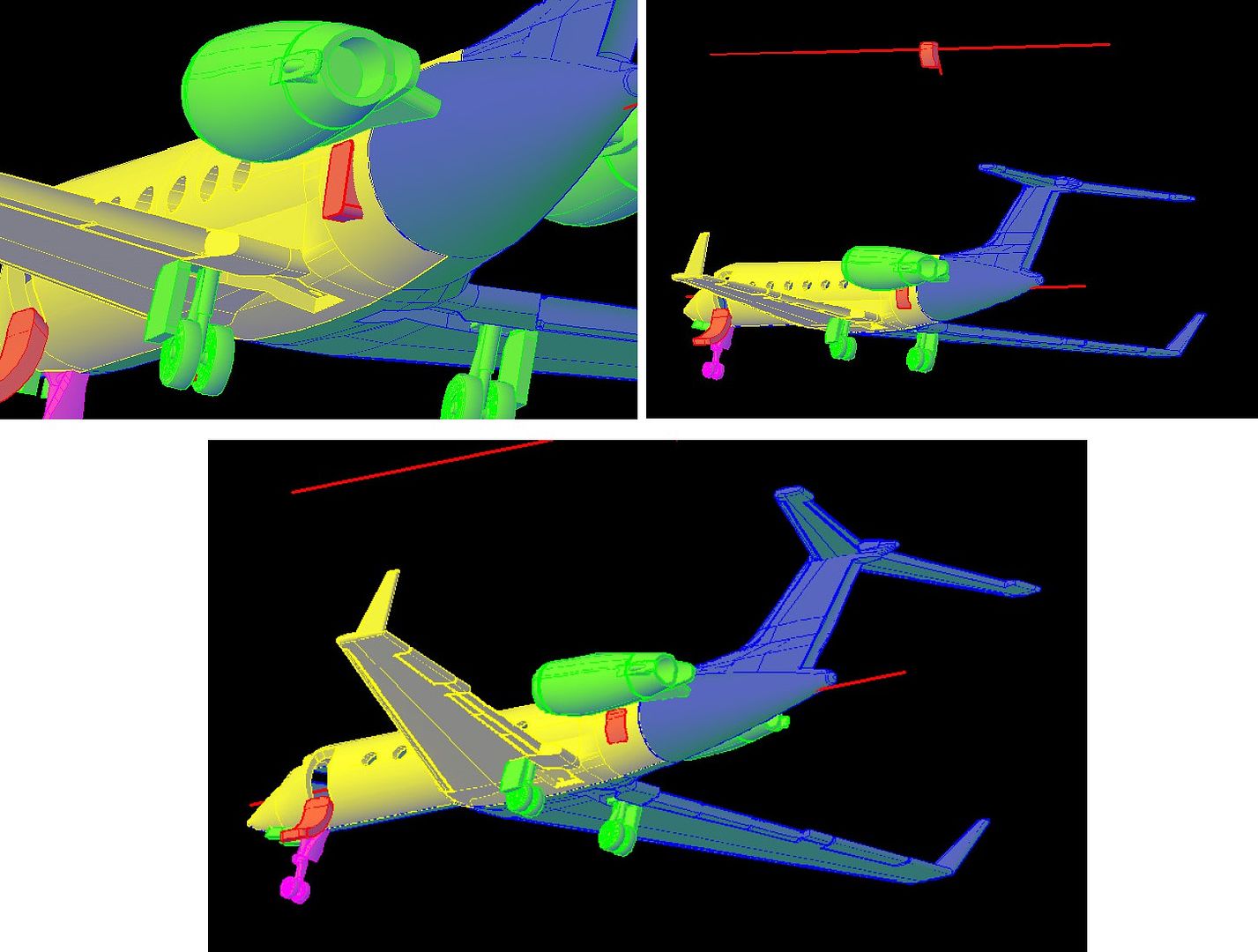

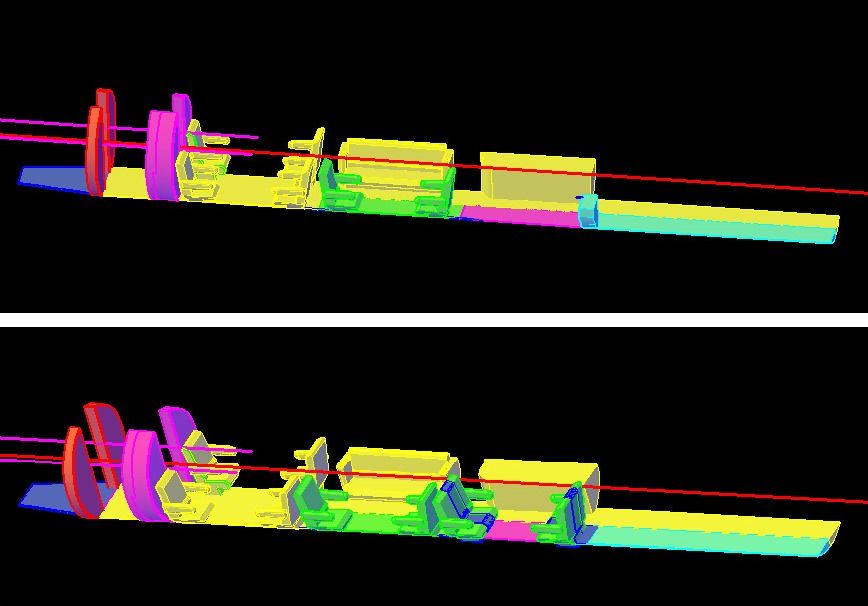

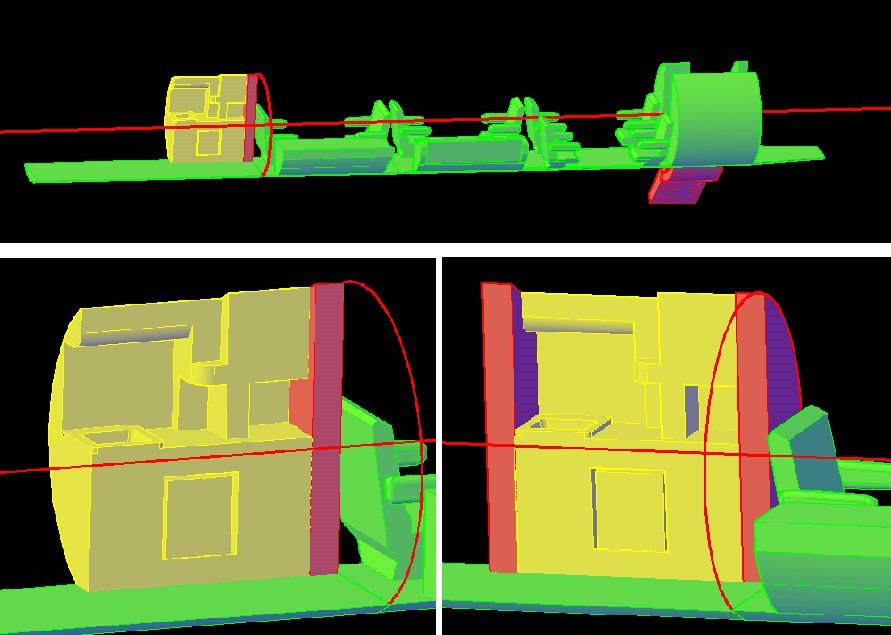

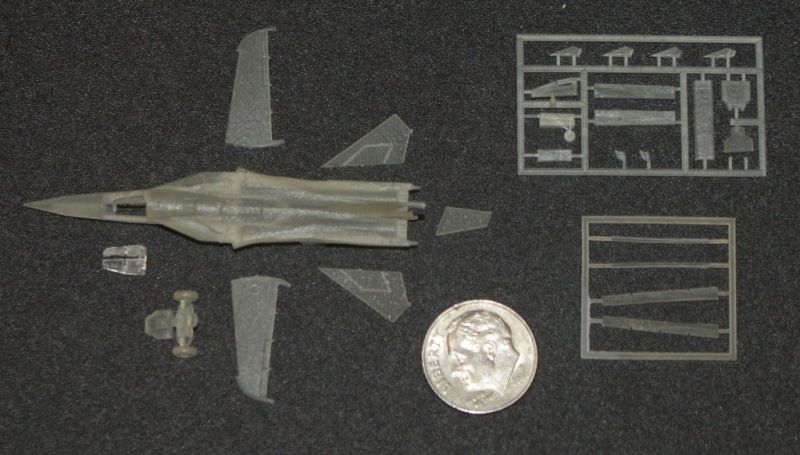

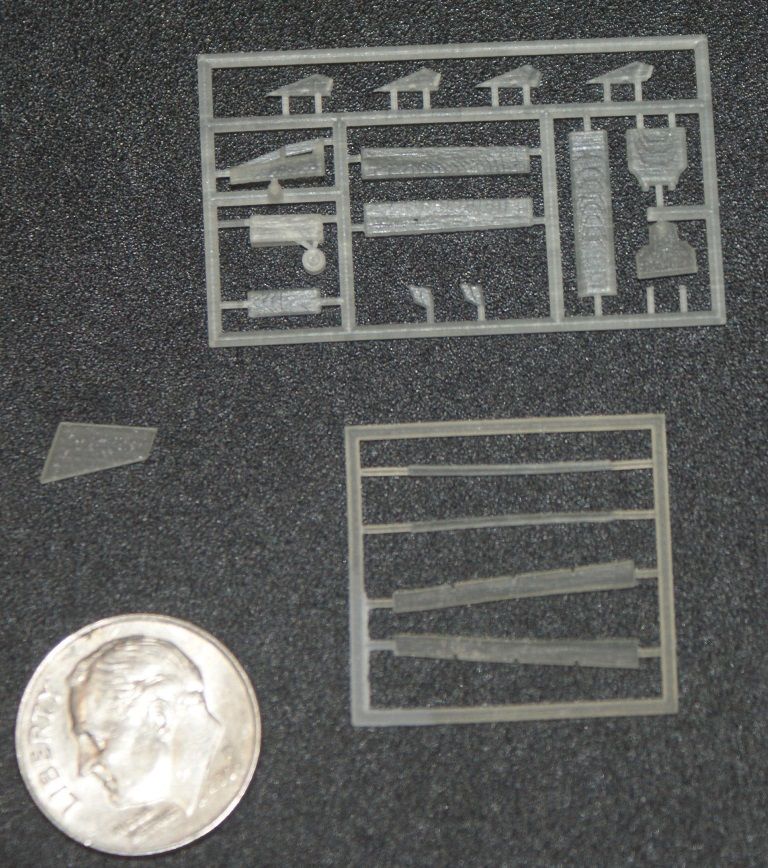

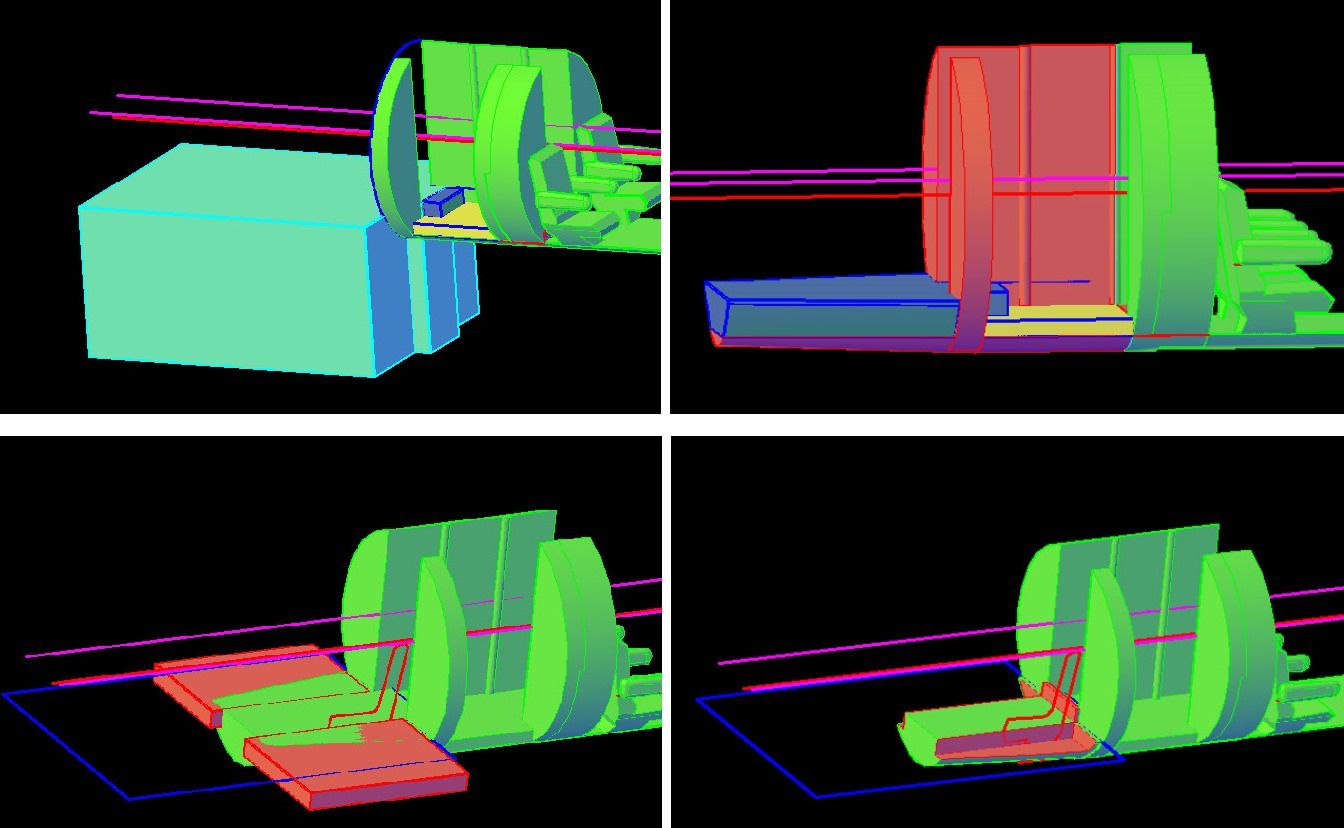

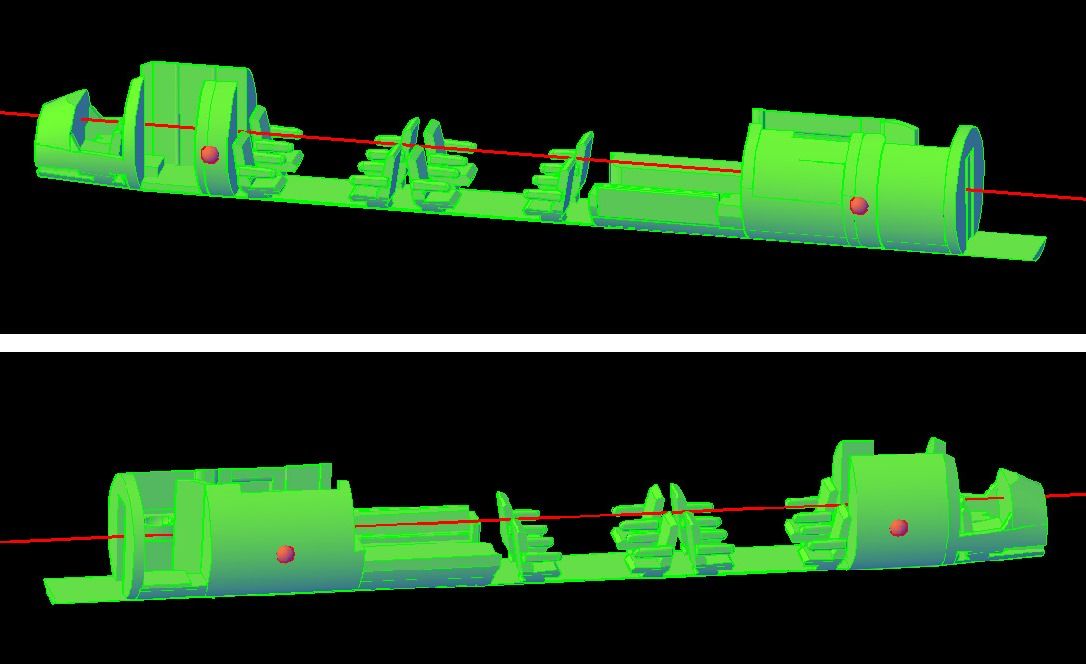

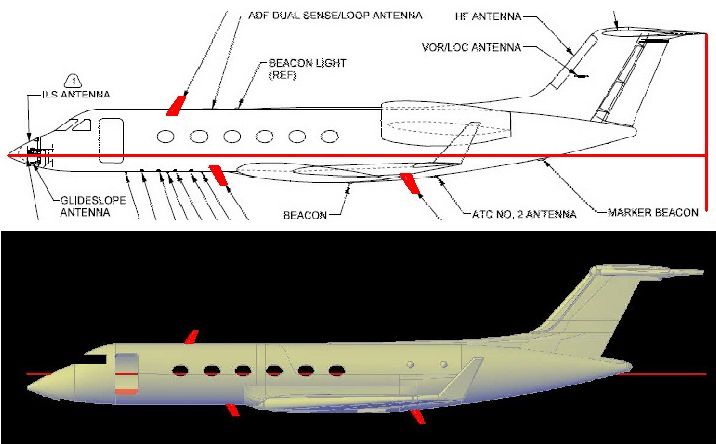

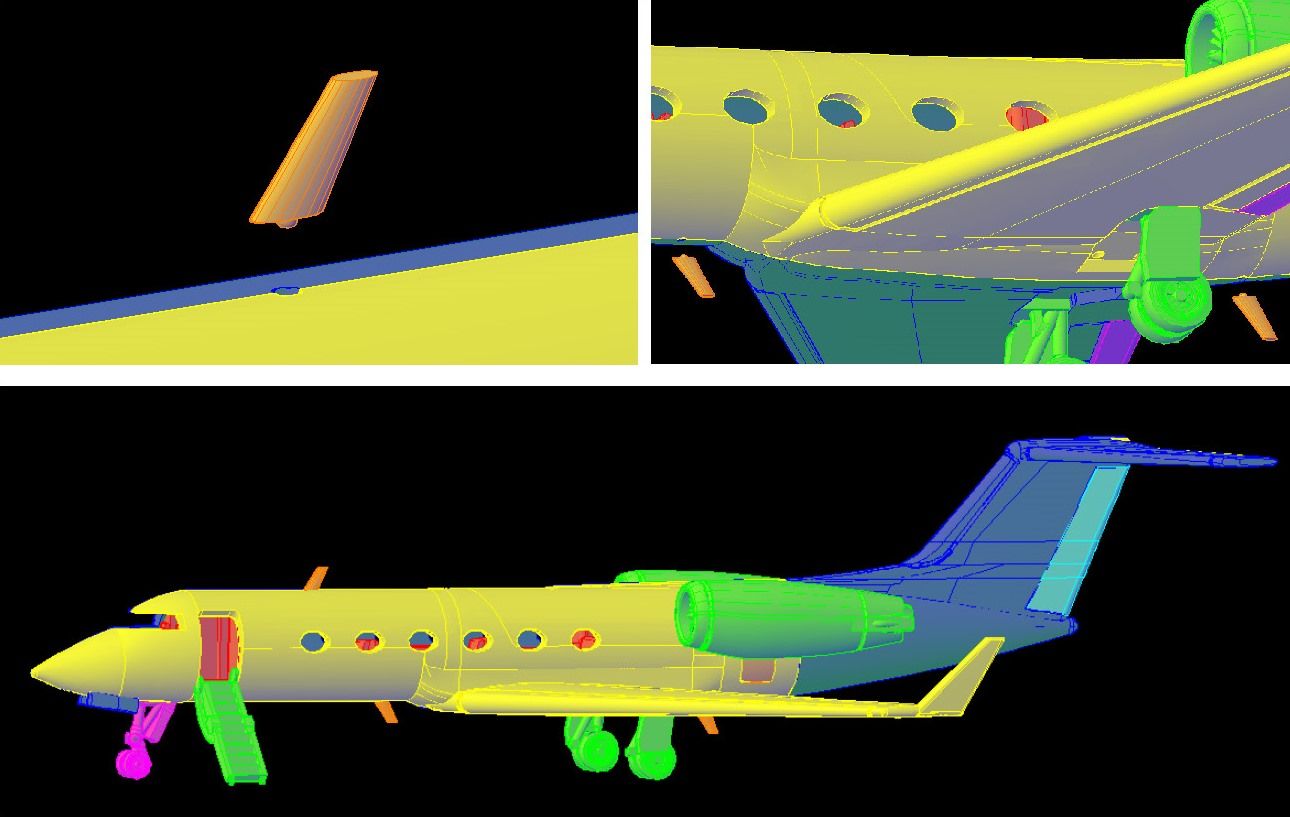

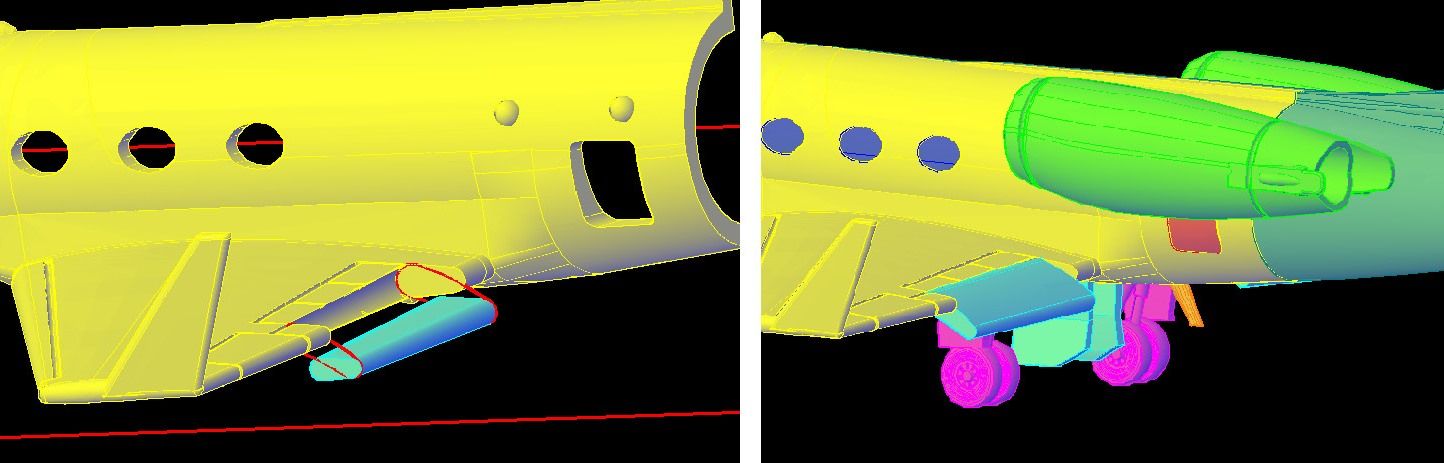

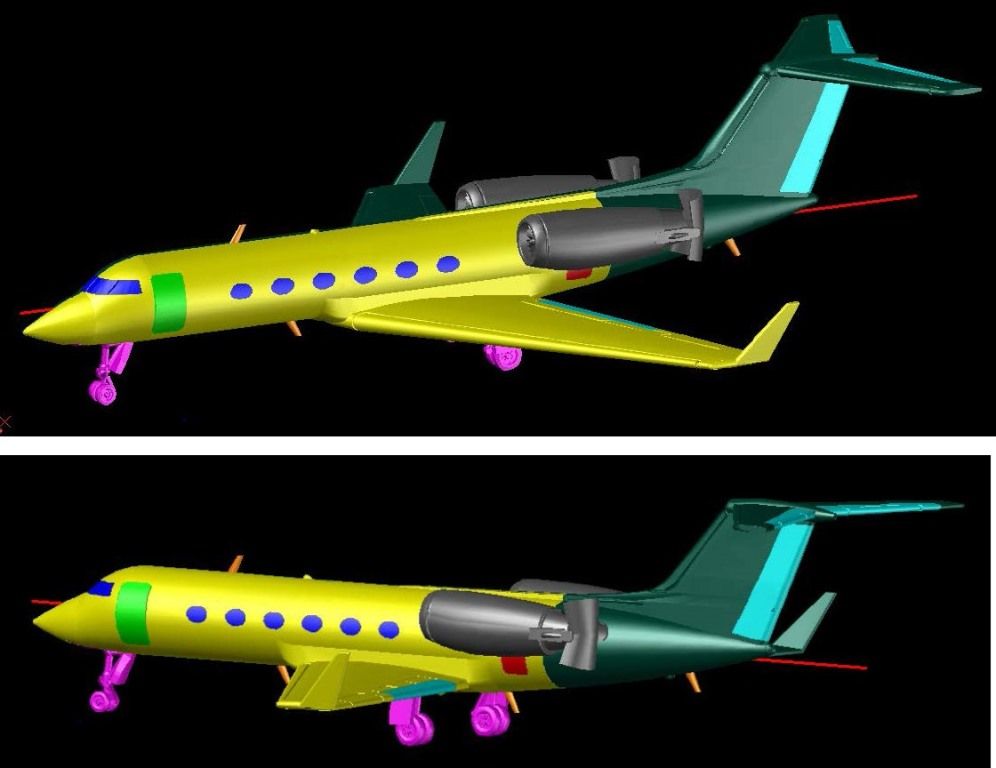

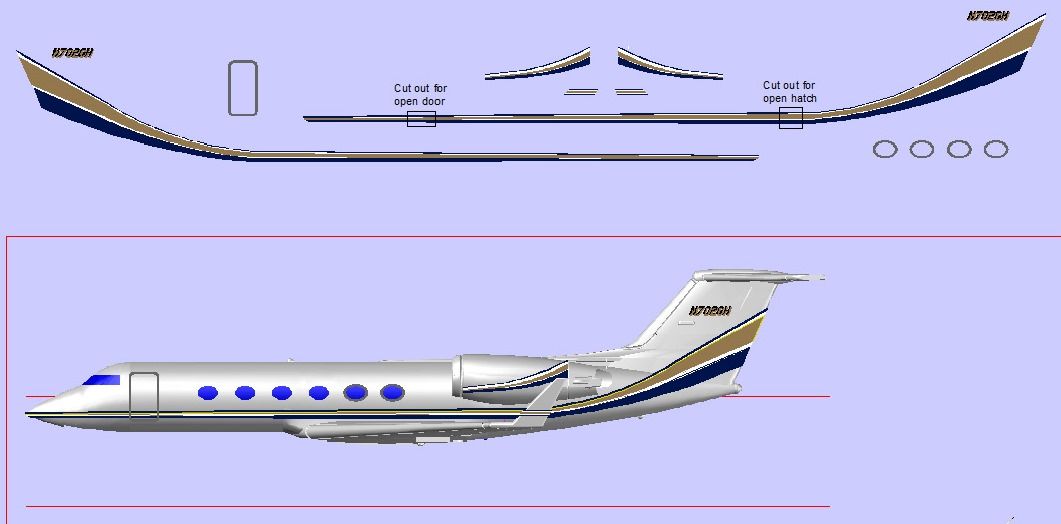

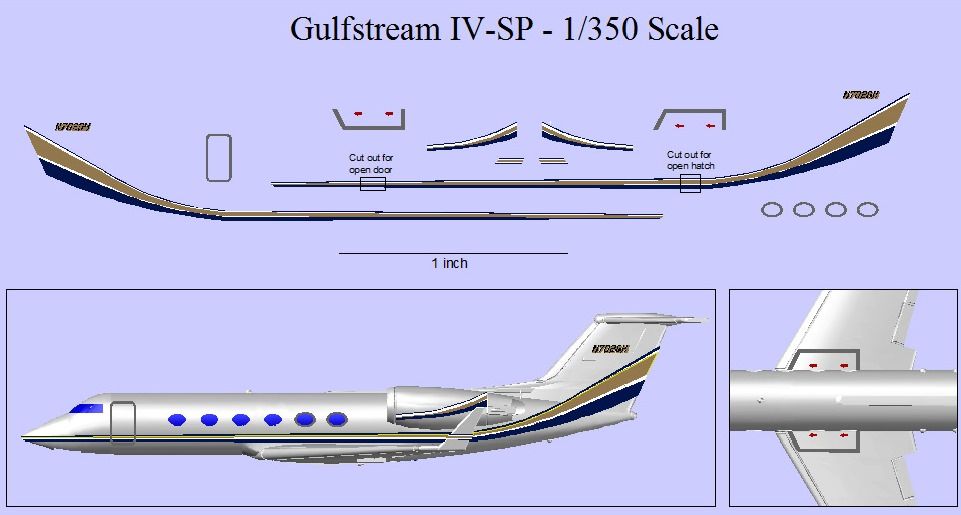

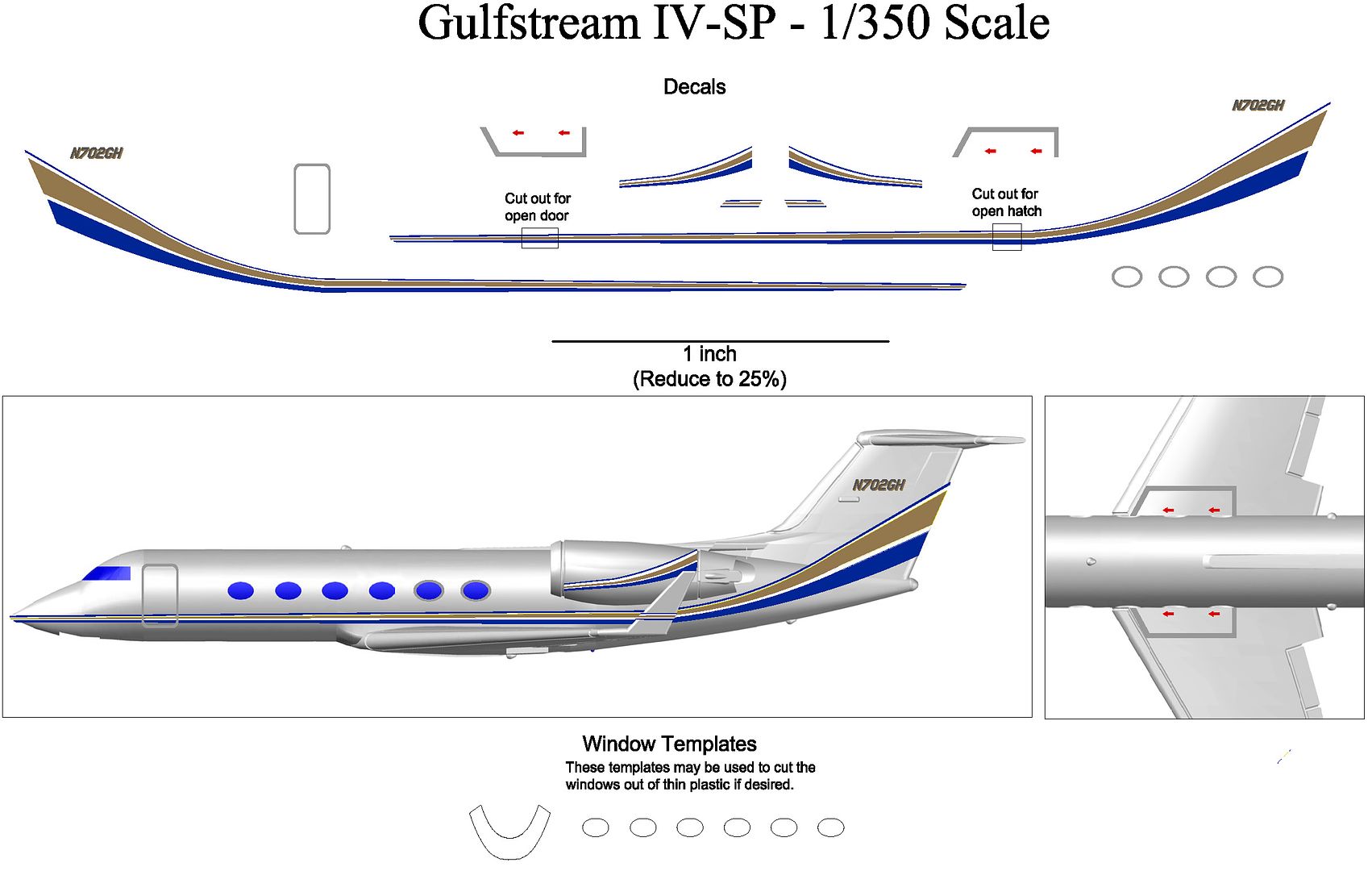

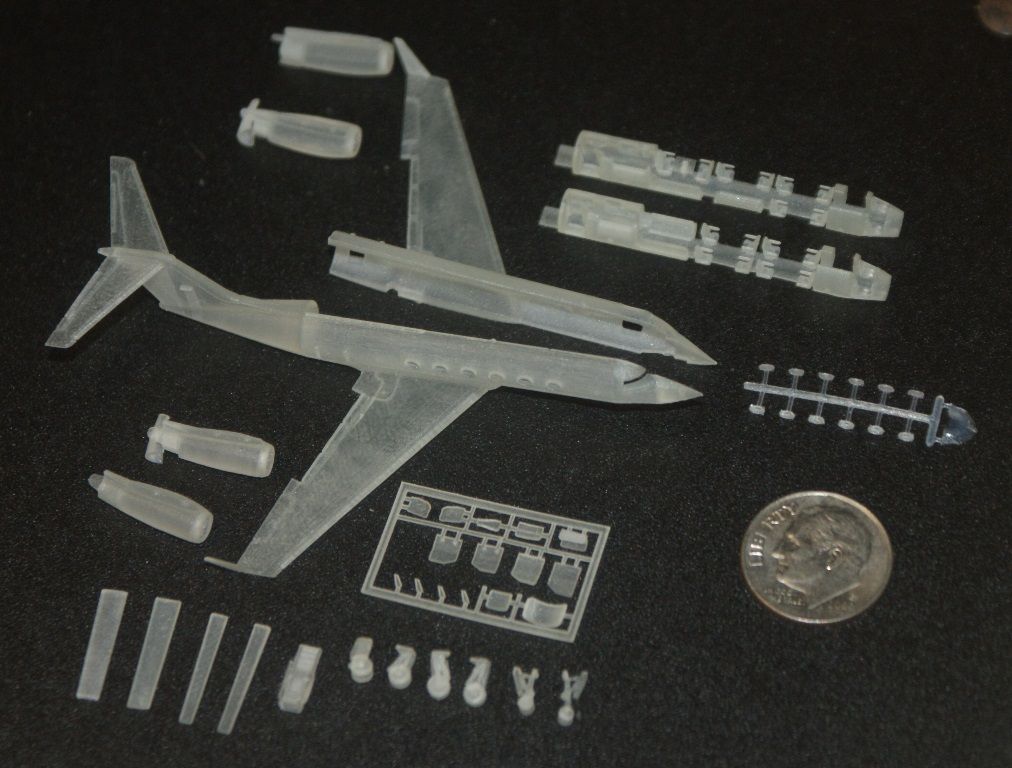

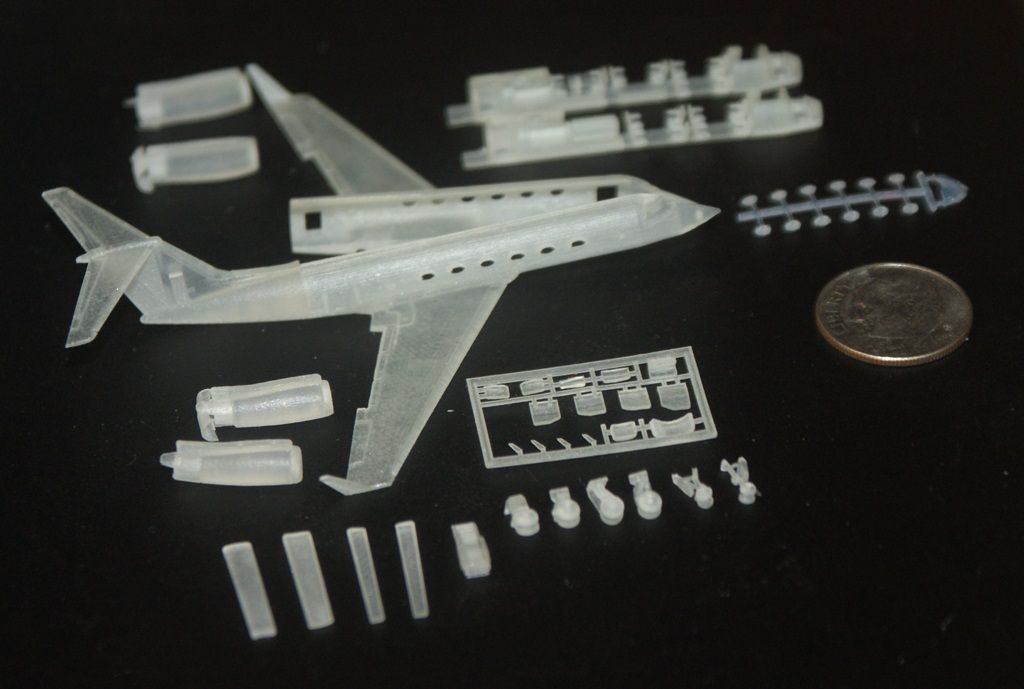

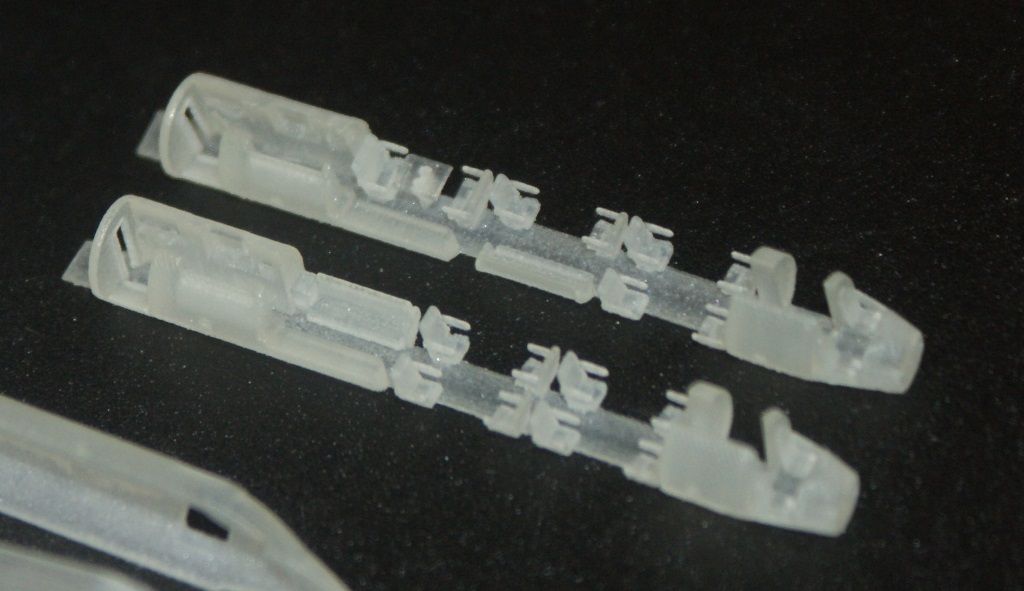

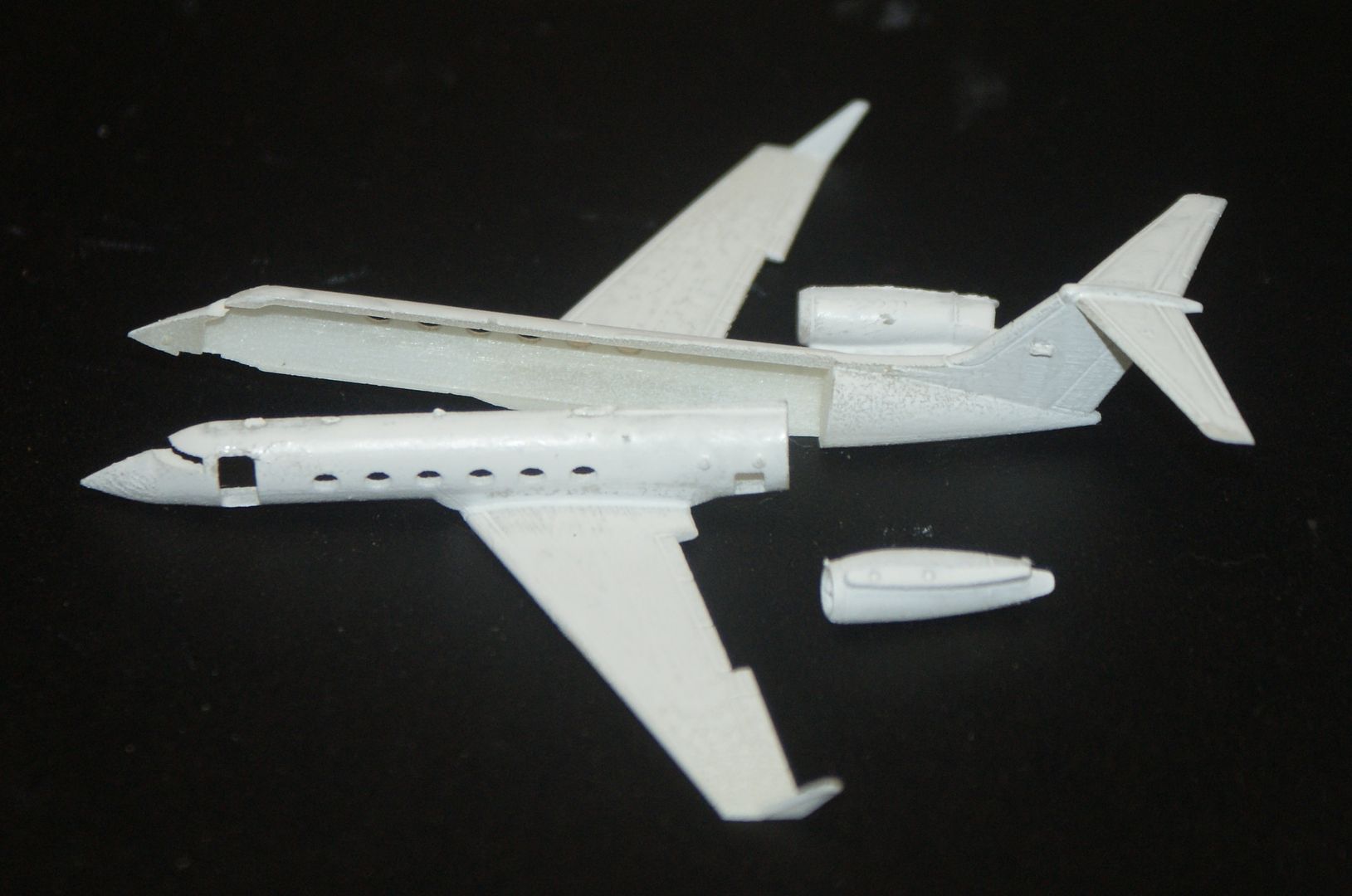

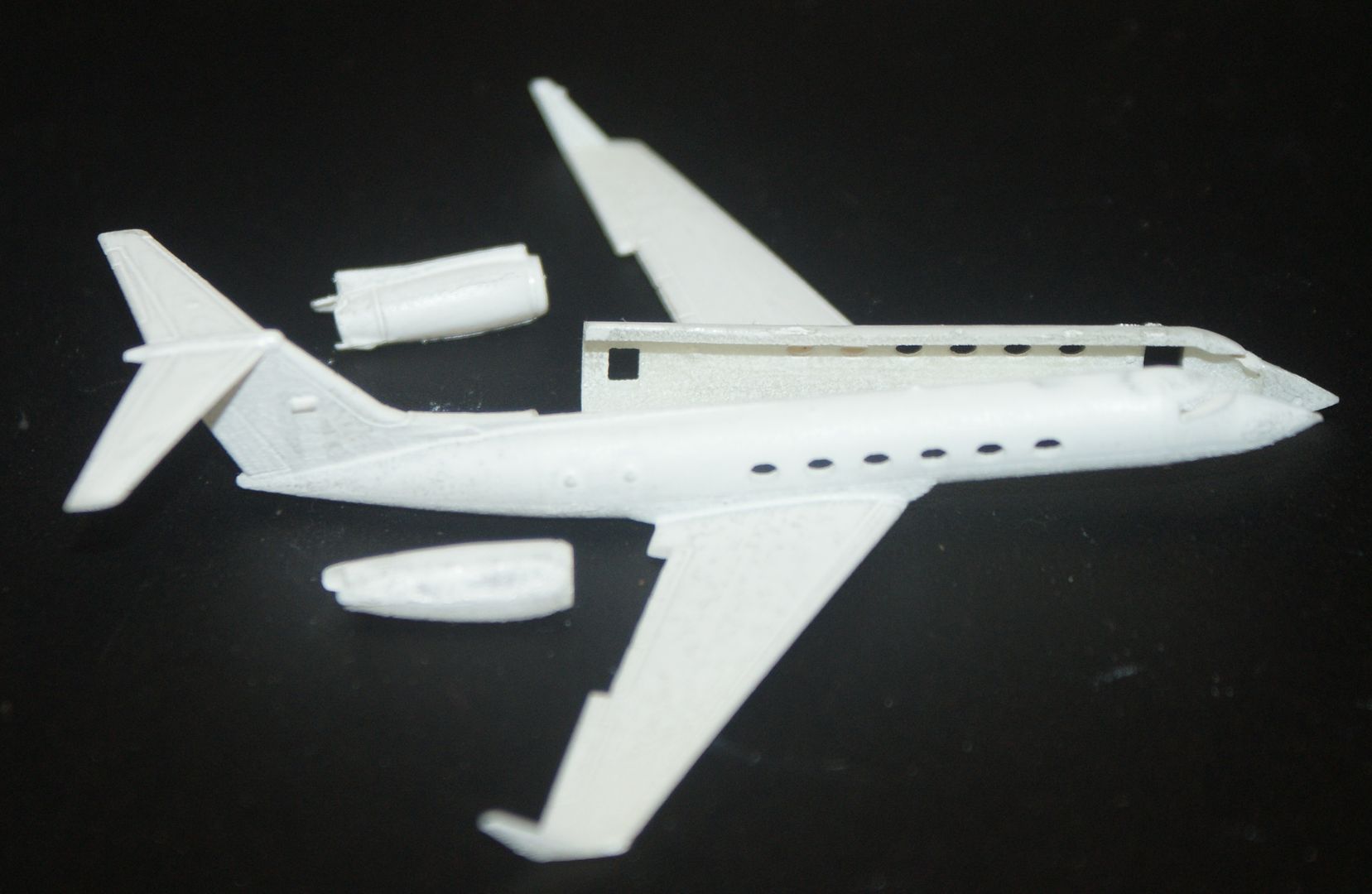

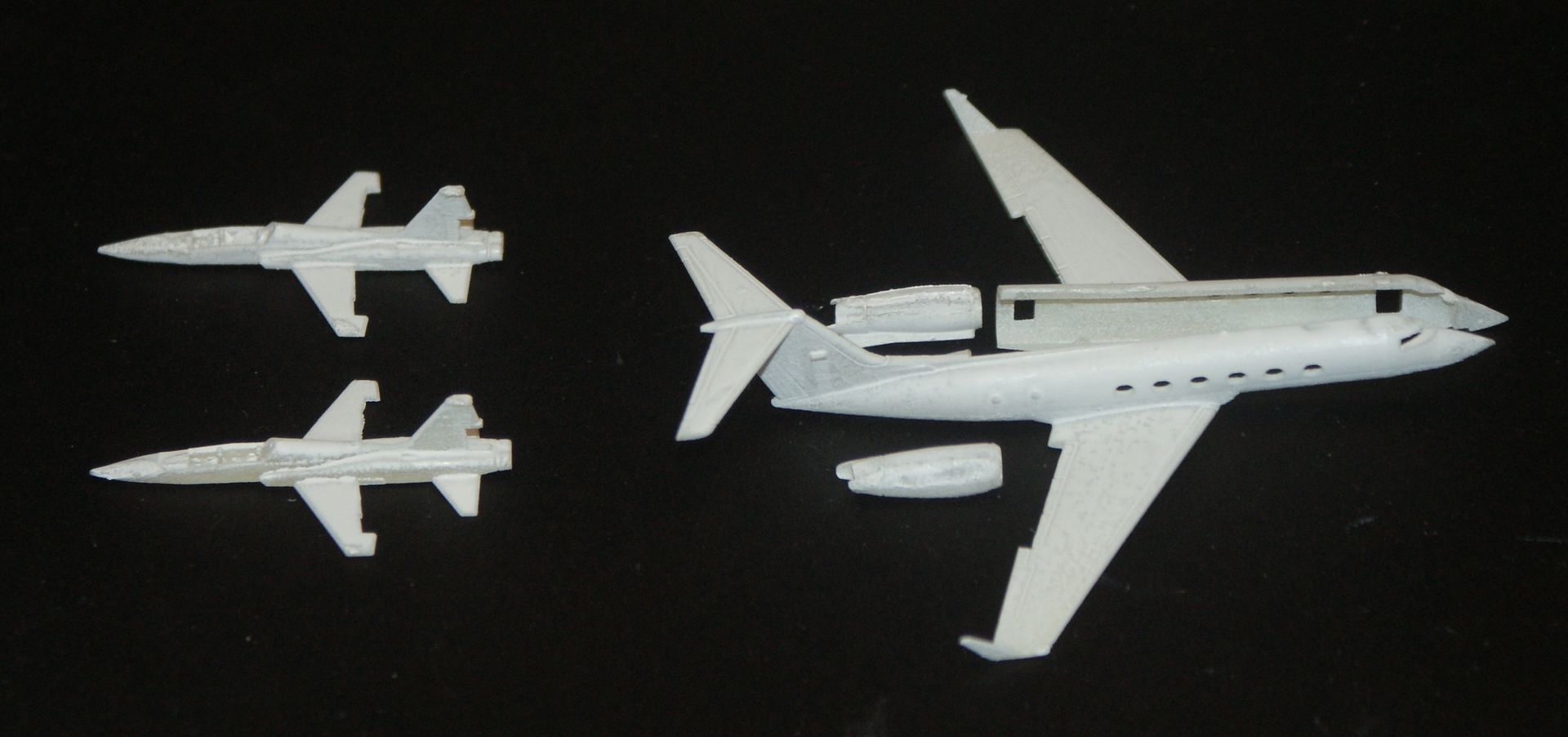

I woke up in the middle of the night, wide awake, so I got up and played on the GIV. Working on the interior, it occurred to me that the baggage room in the back had to have an outside access door. Sure enough, a look at the plans and poring through pix revealed that there is indeed a door below the left engine. The images below show the process which, by now, you probably know by heart. Trace, copy, extrude, copy, union, subtract, move.

In the few pictures of the GIV I have, showing the access door open, the door itself cannot be seen. Ron tells me it is on a track and opens in and up. At this point I am not going to do anything about that. If the modeler wants the door open, they can simply leave the door off, or attach it on the inside, as they see fit.

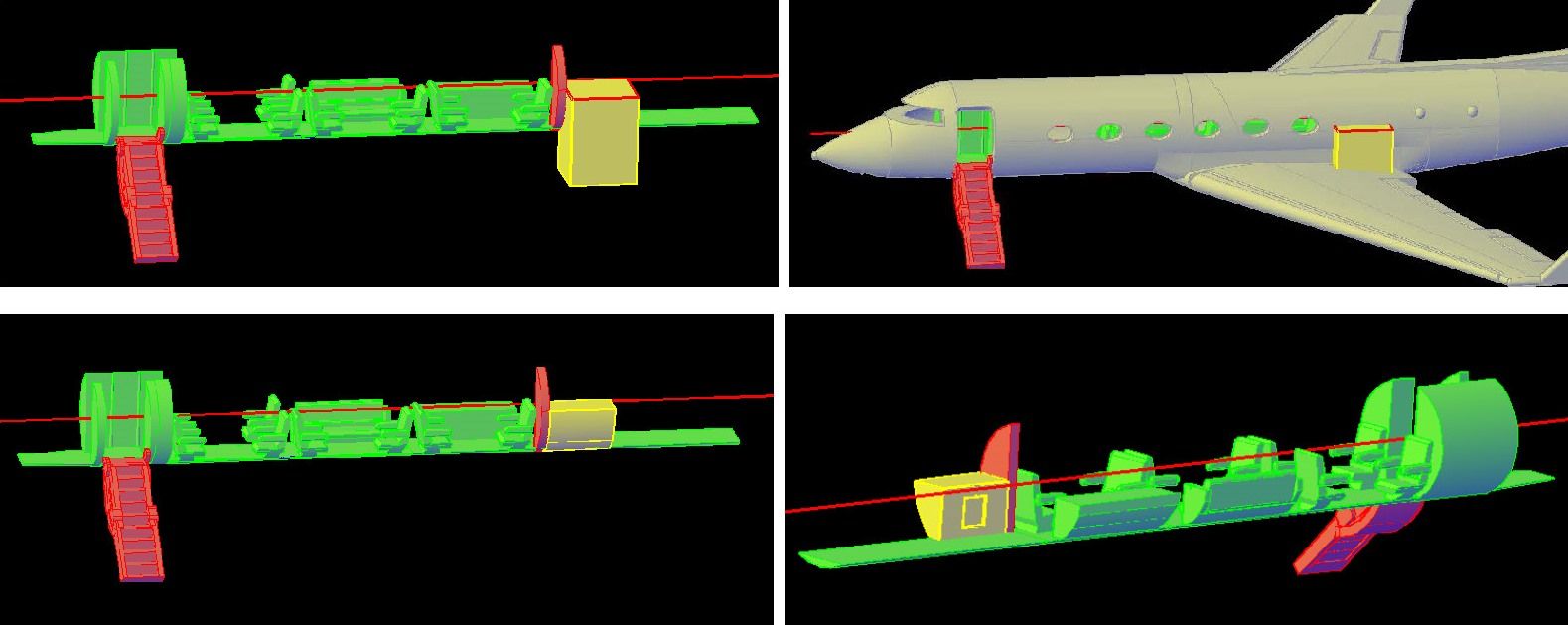

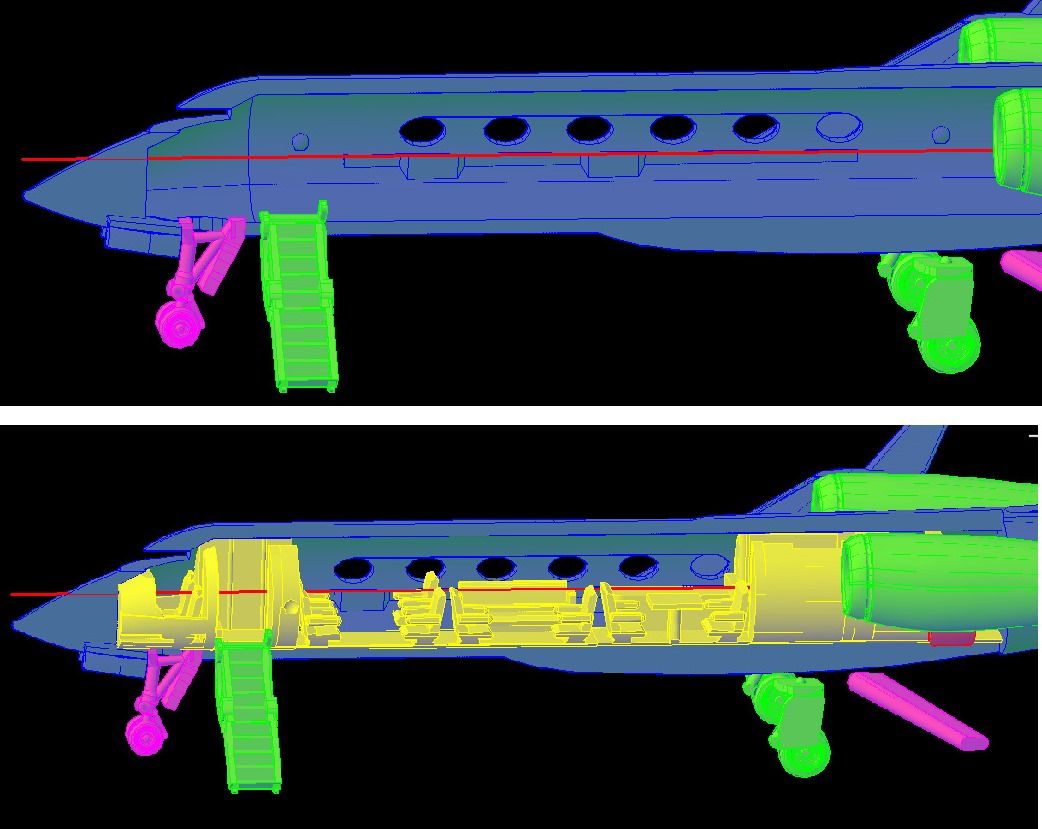

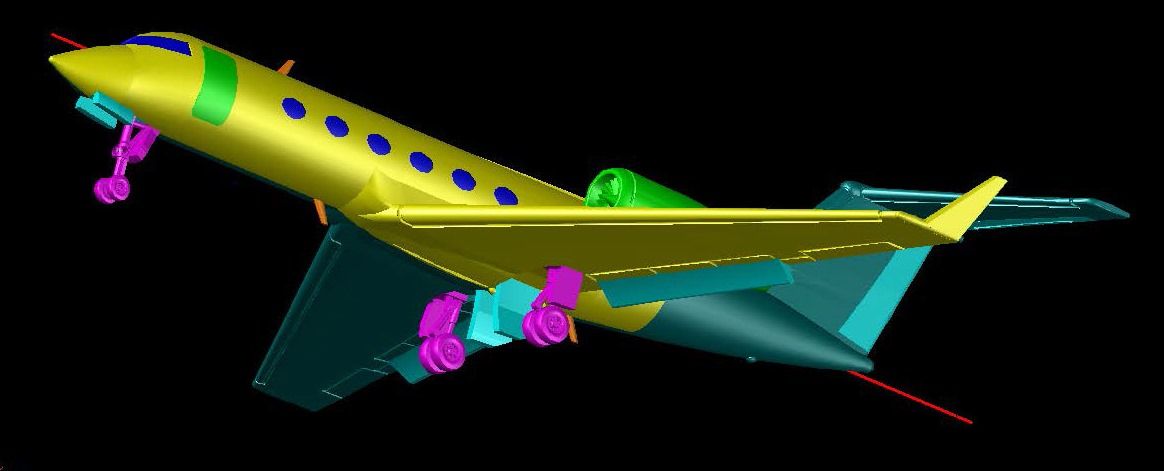

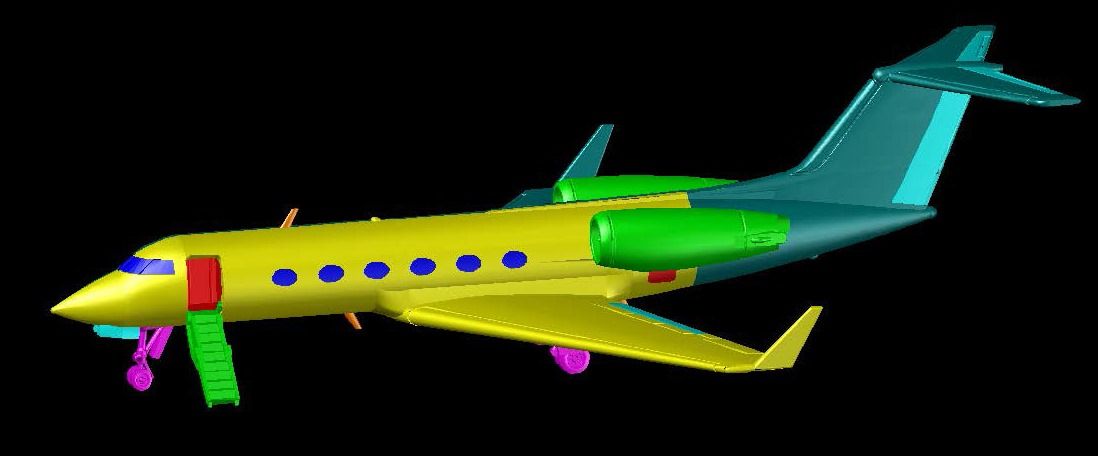

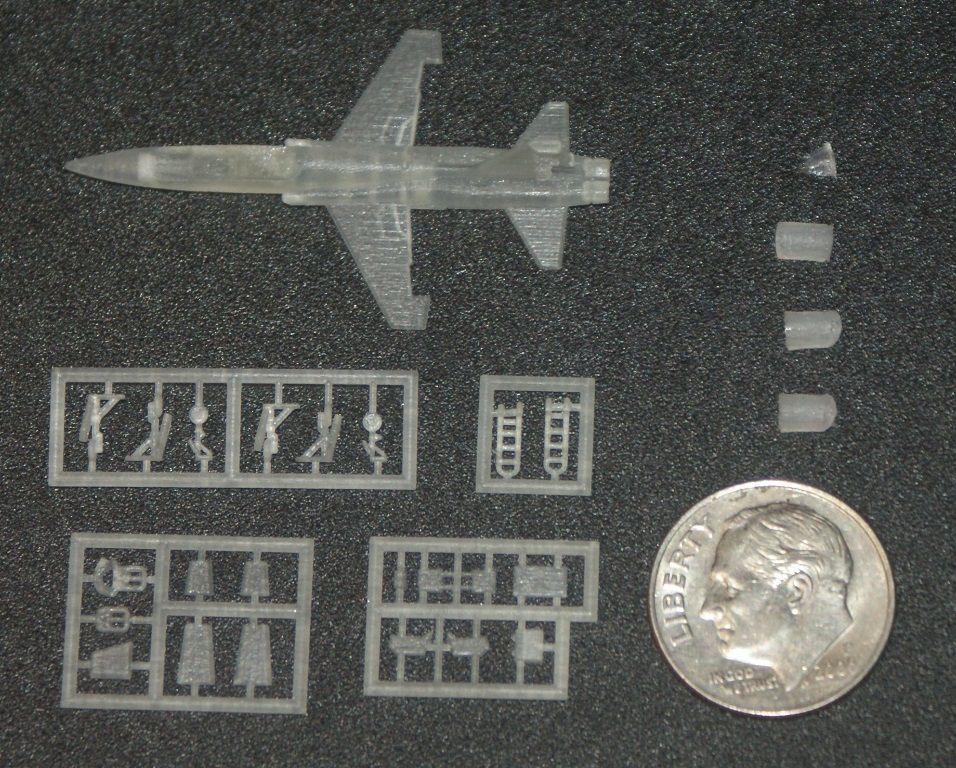

Instead, I decided to do the open cabin door and access ladder. Fortunately, I had several pictures to go on, including those shown below.

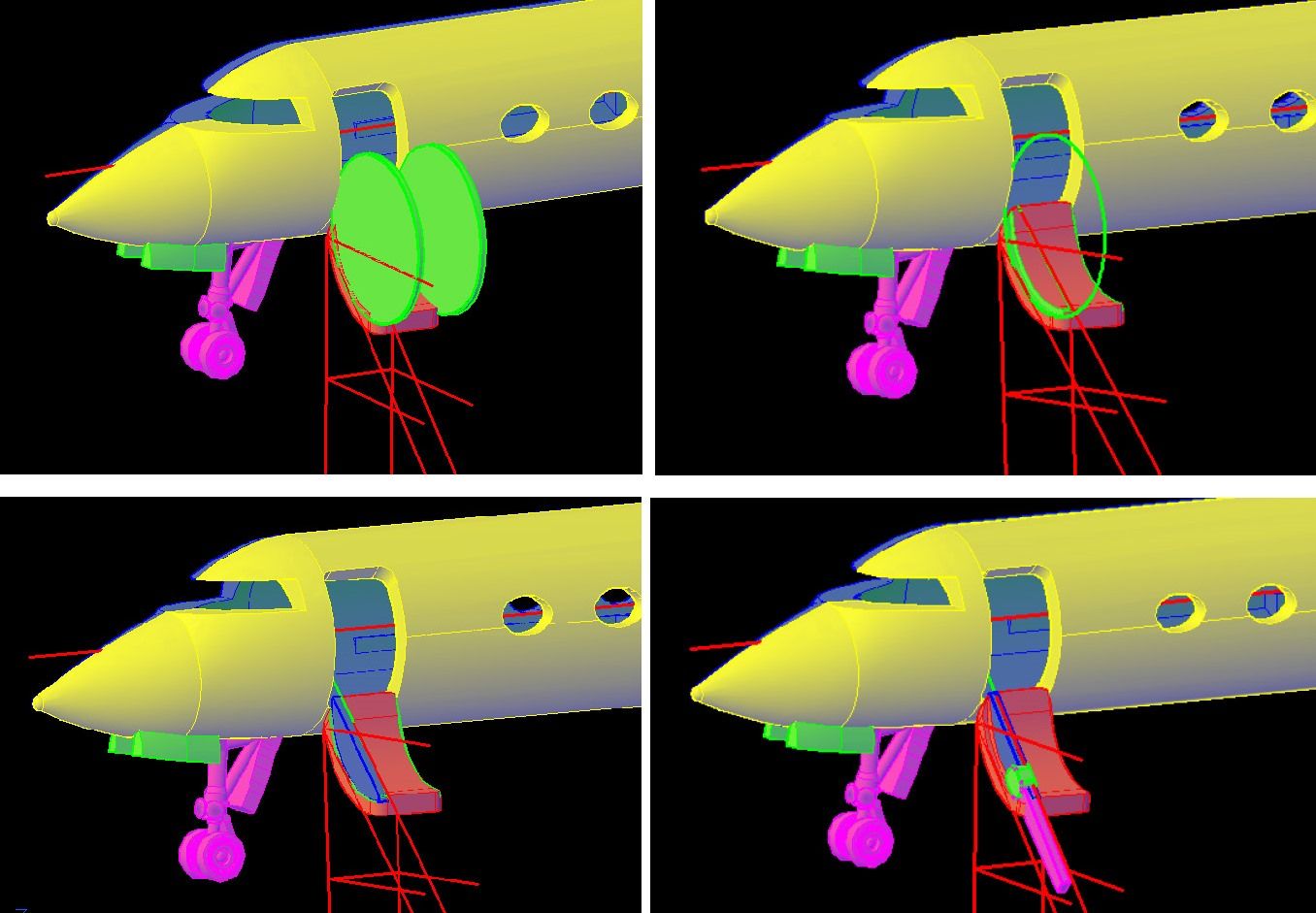

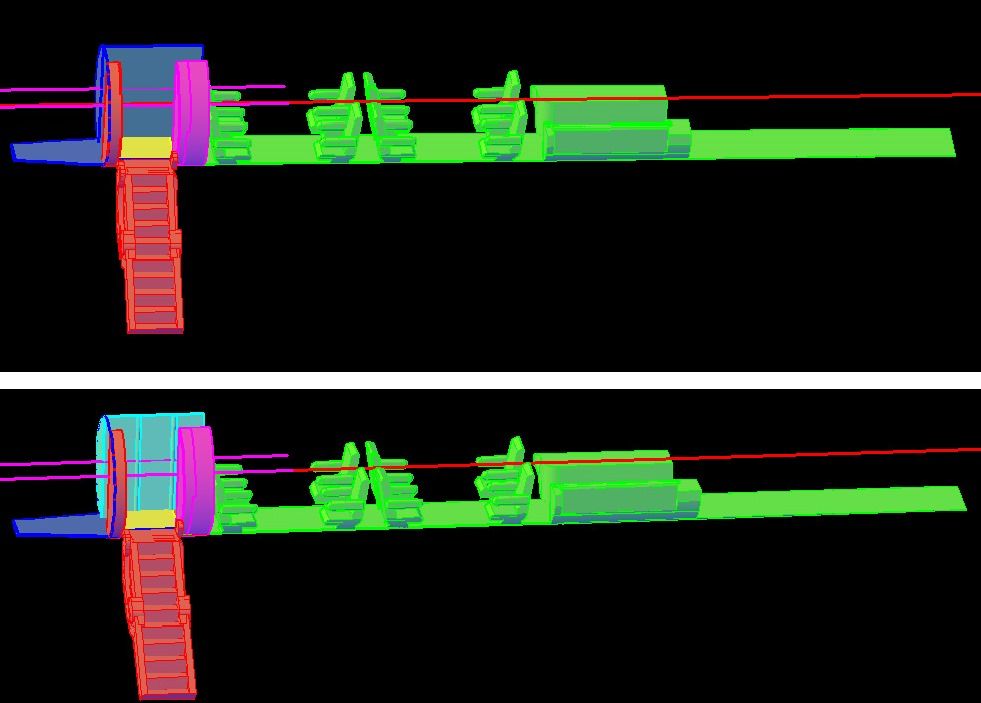

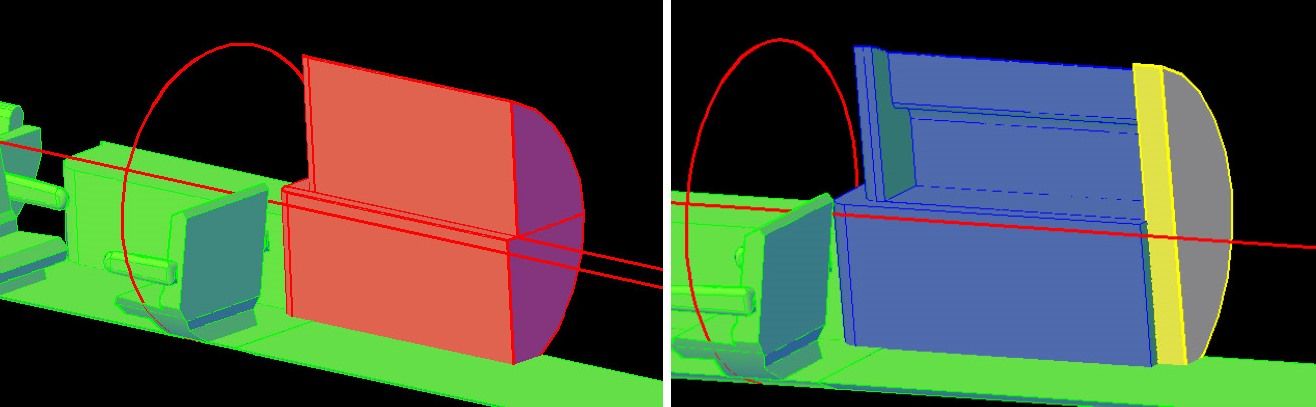

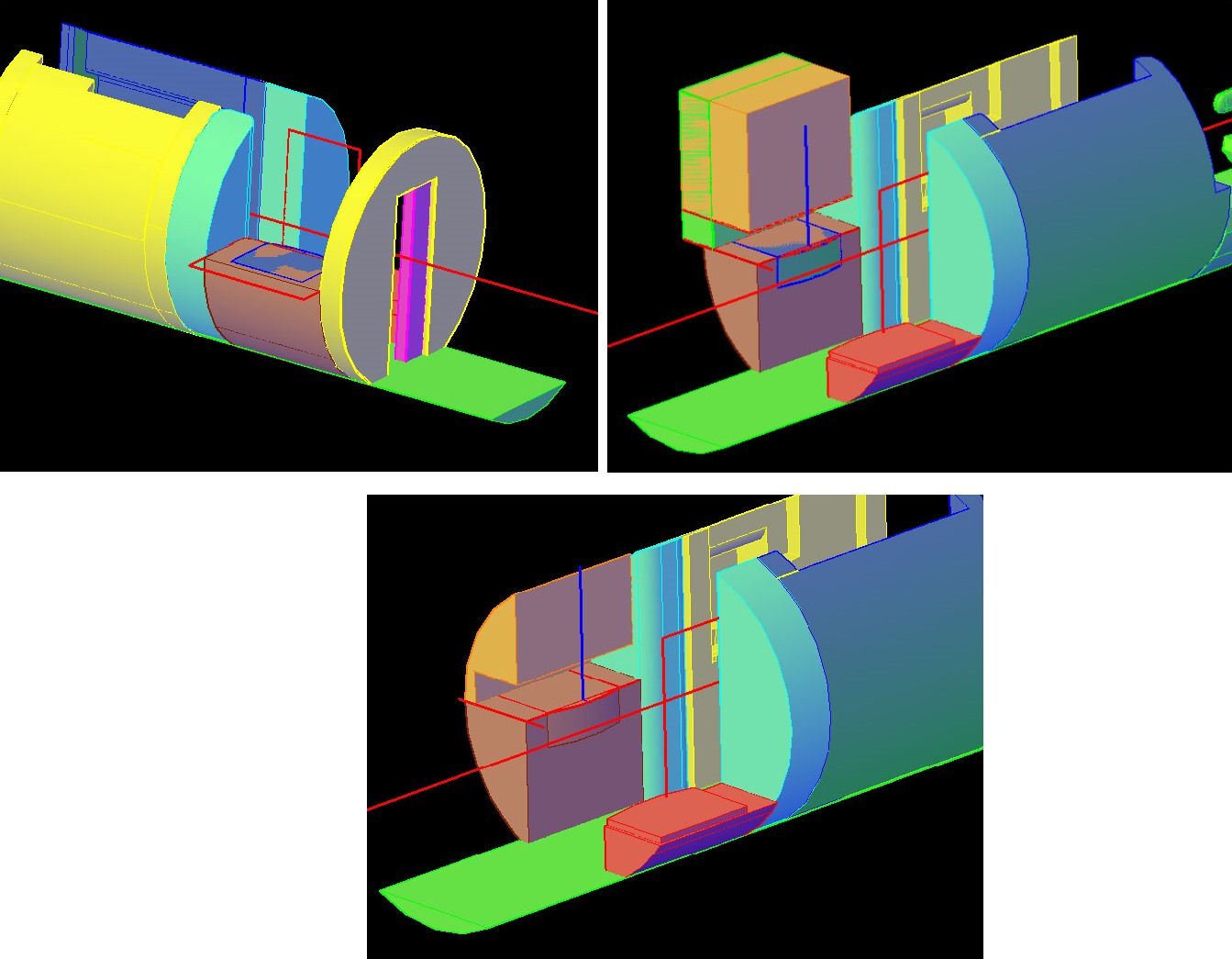

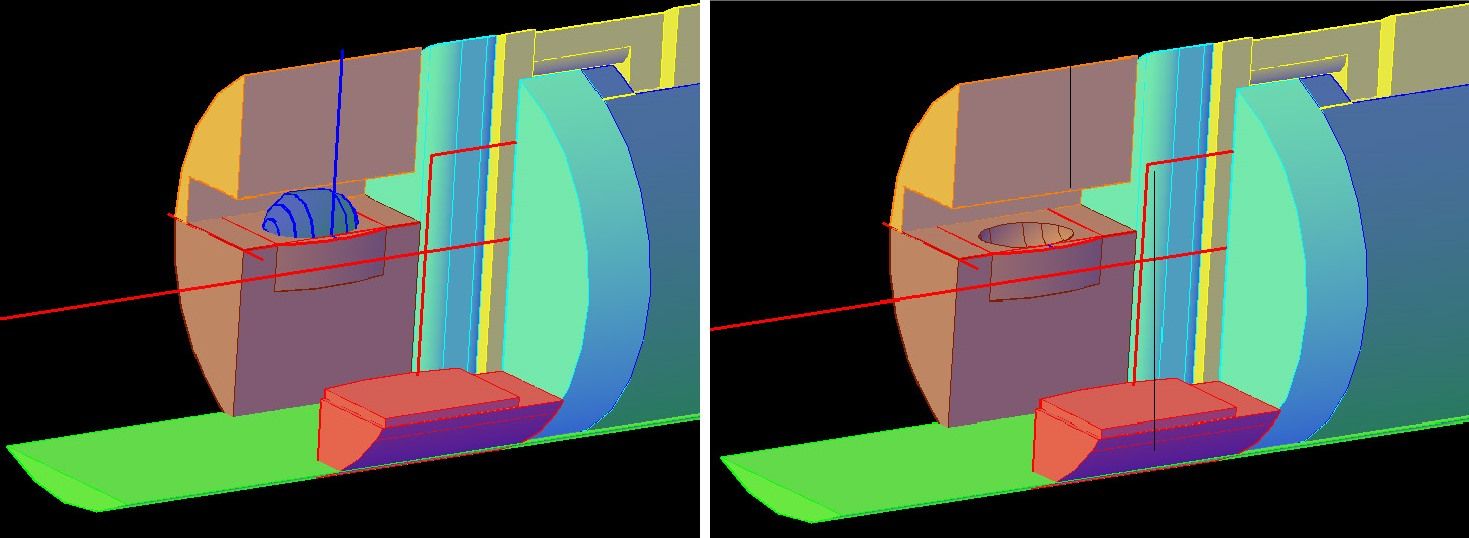

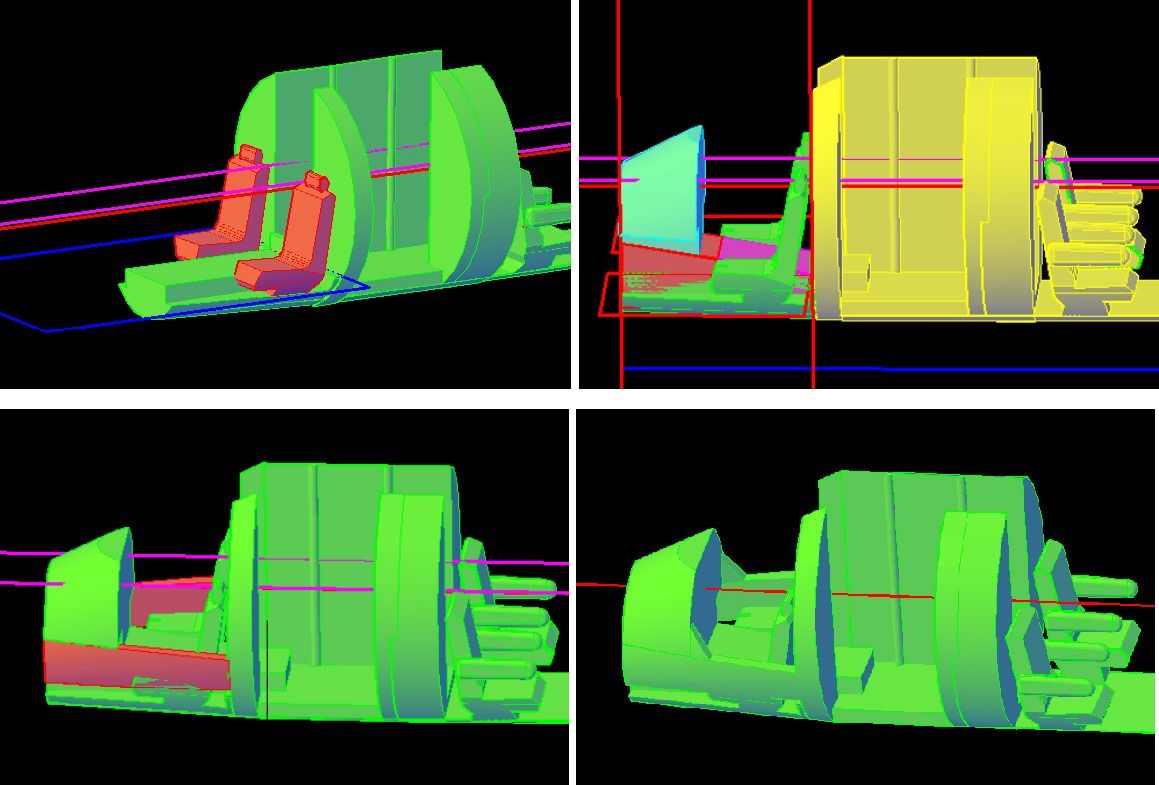

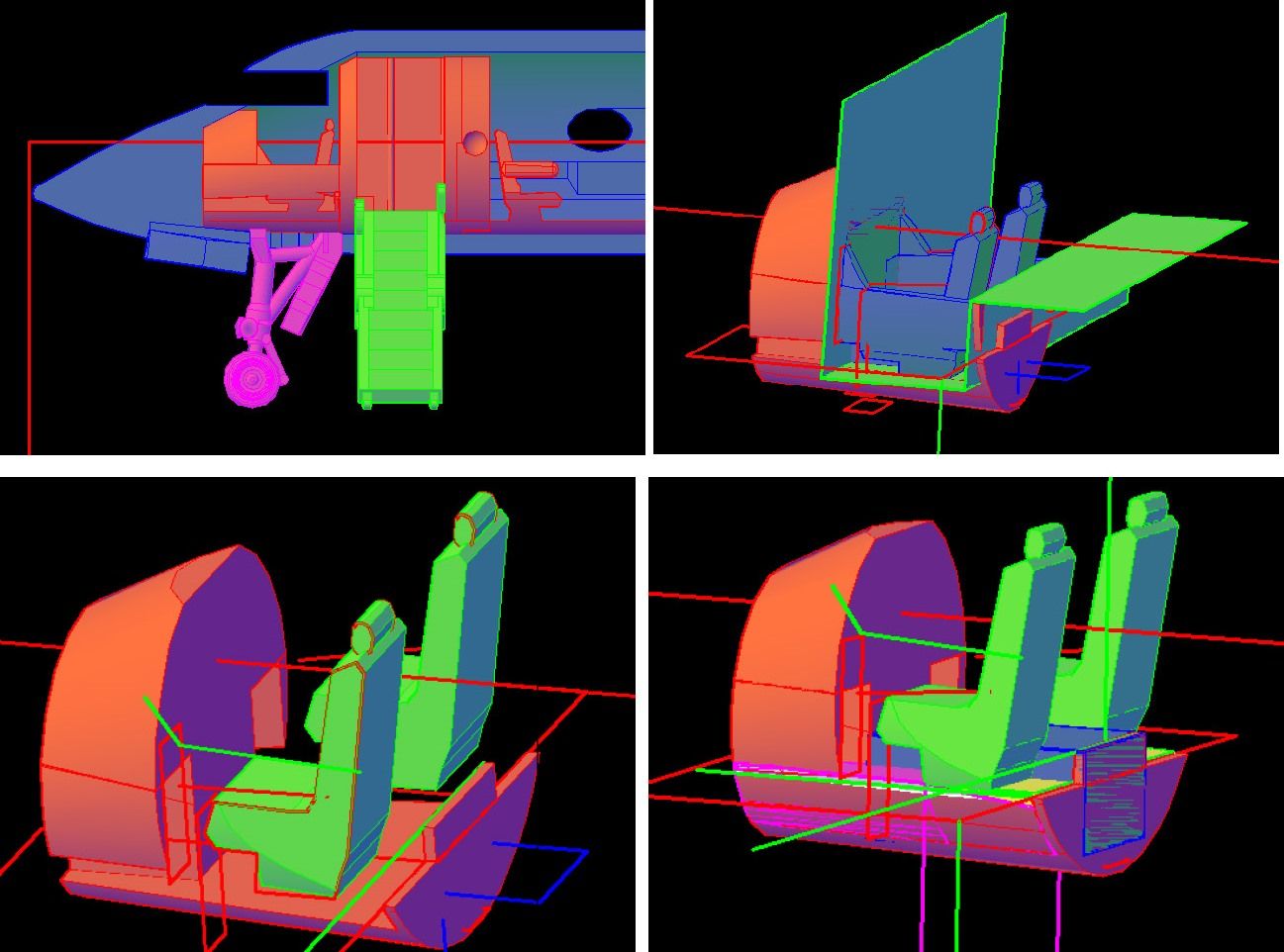

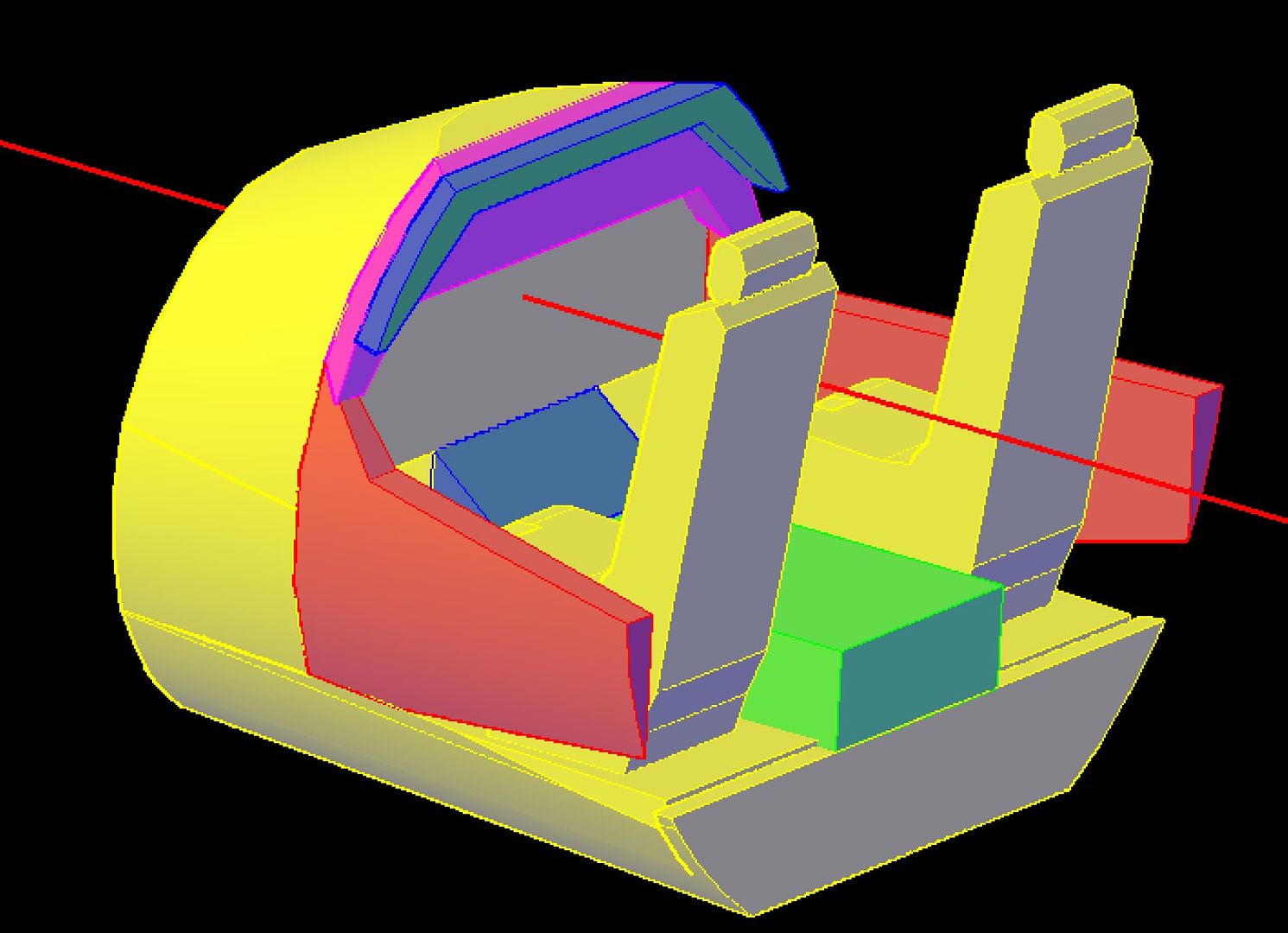

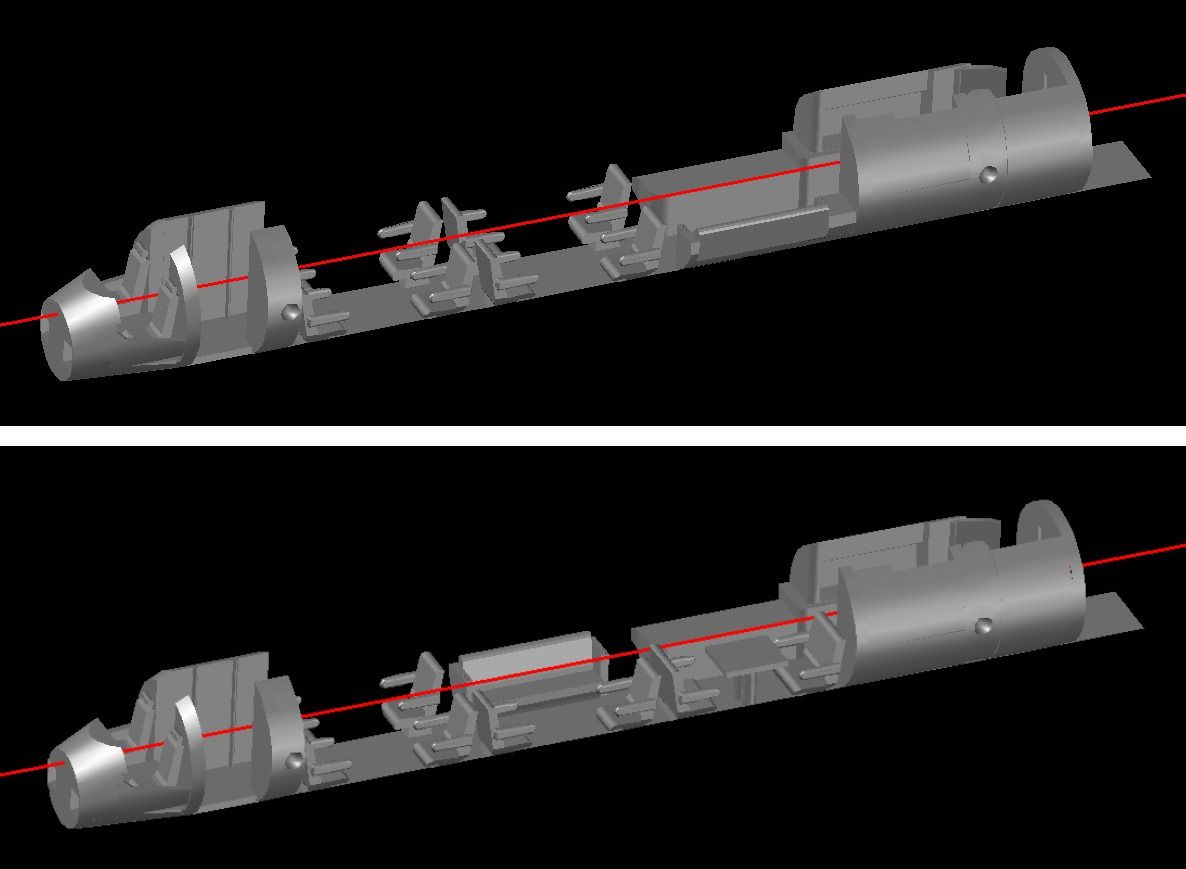

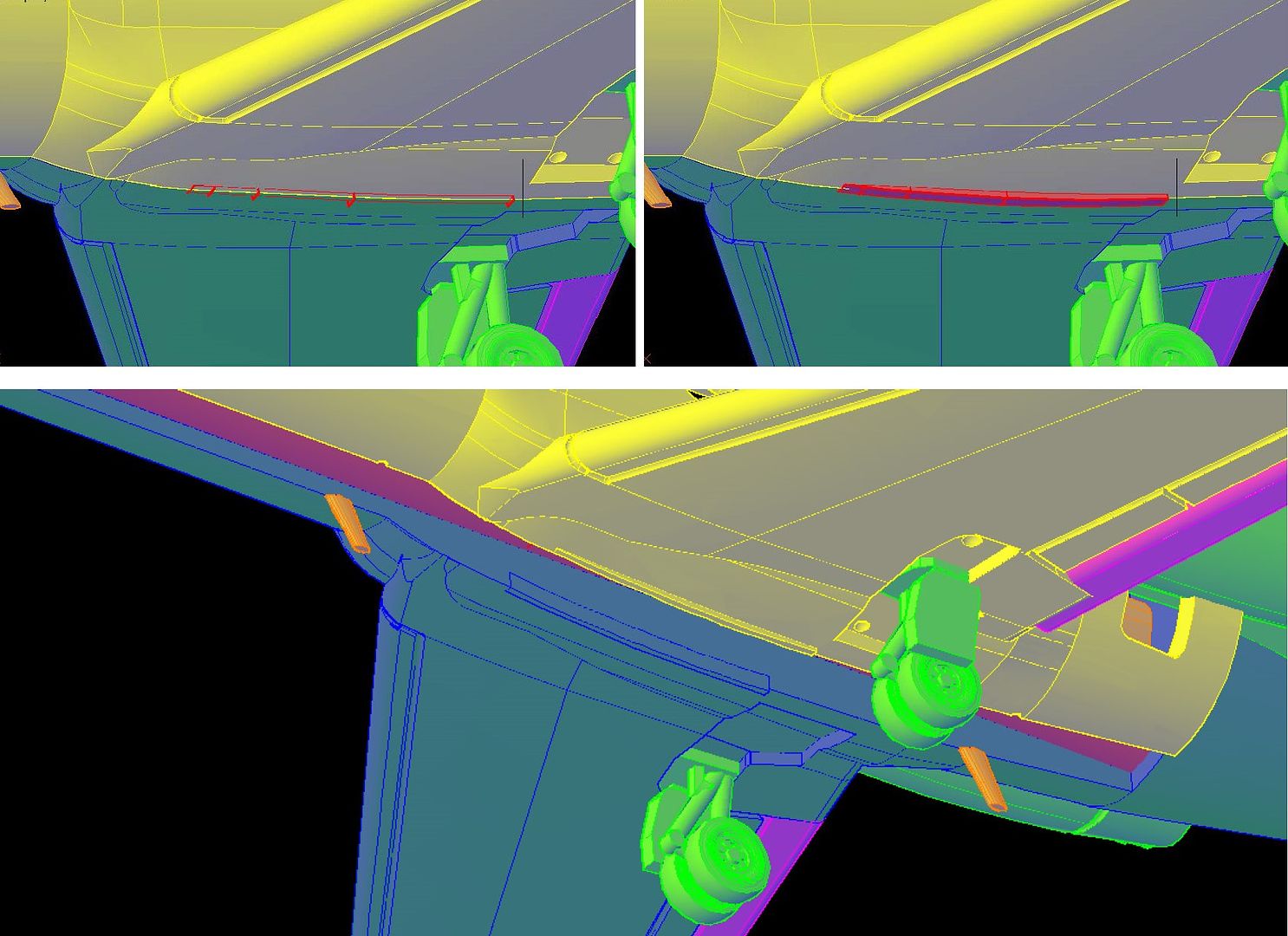

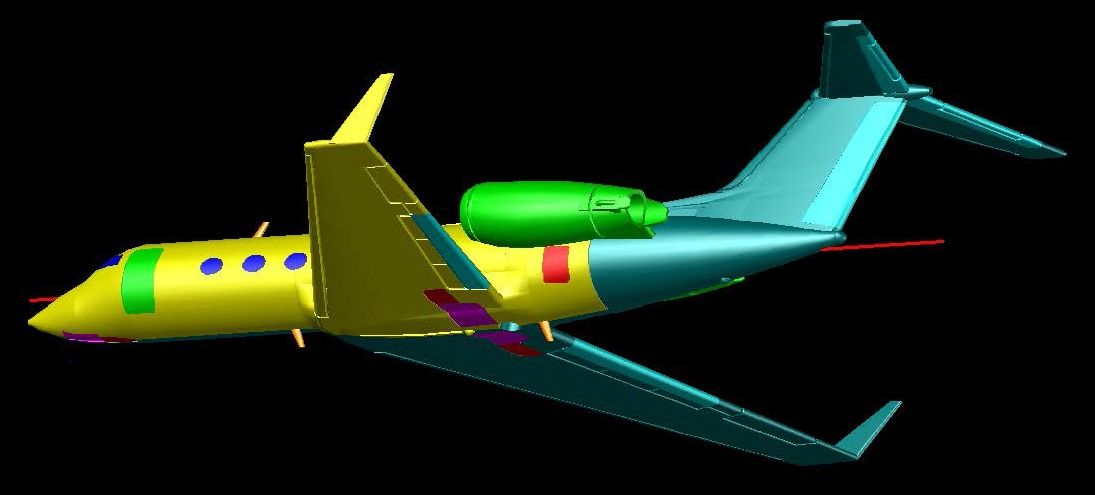

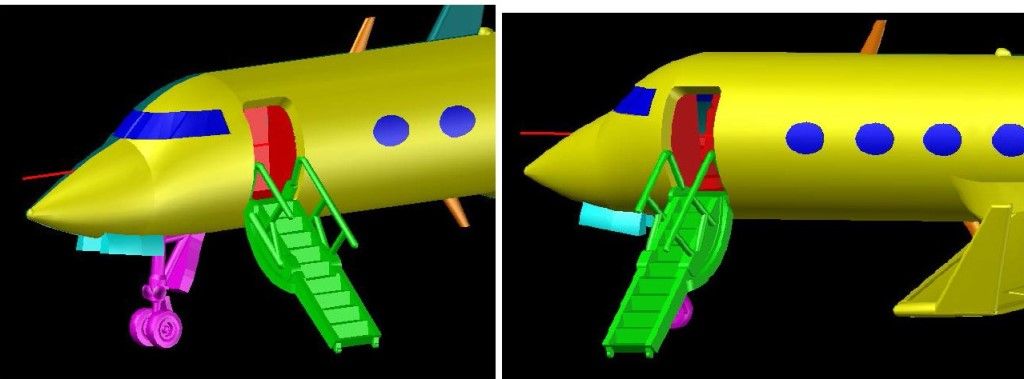

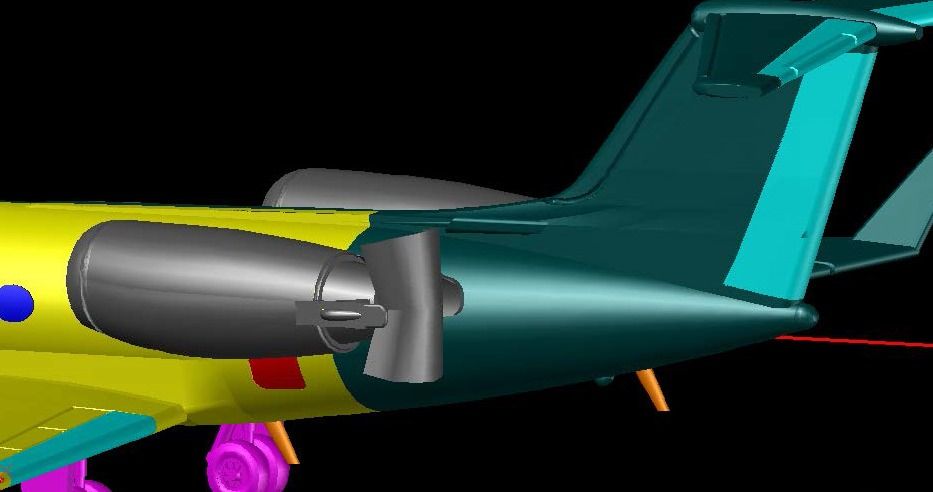

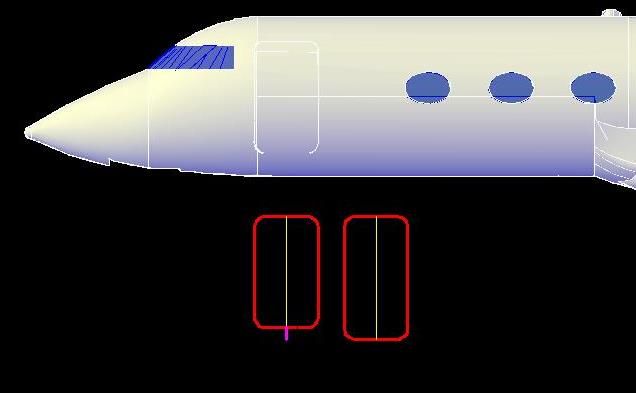

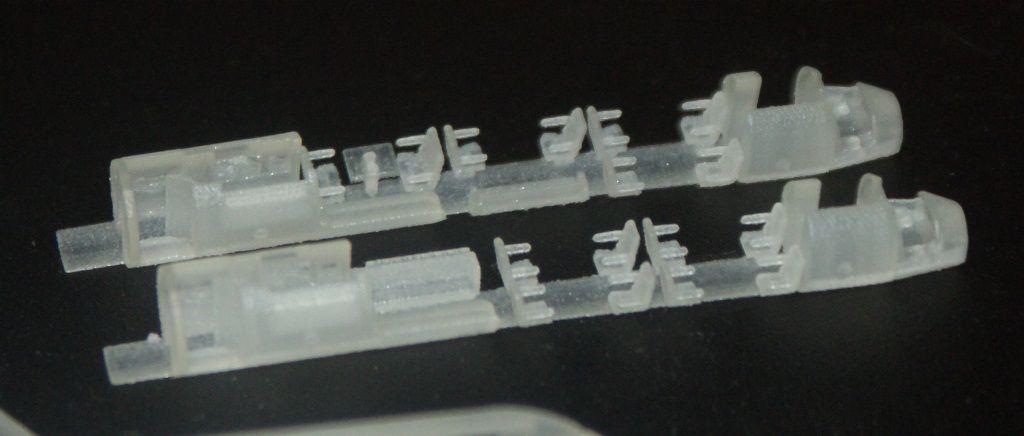

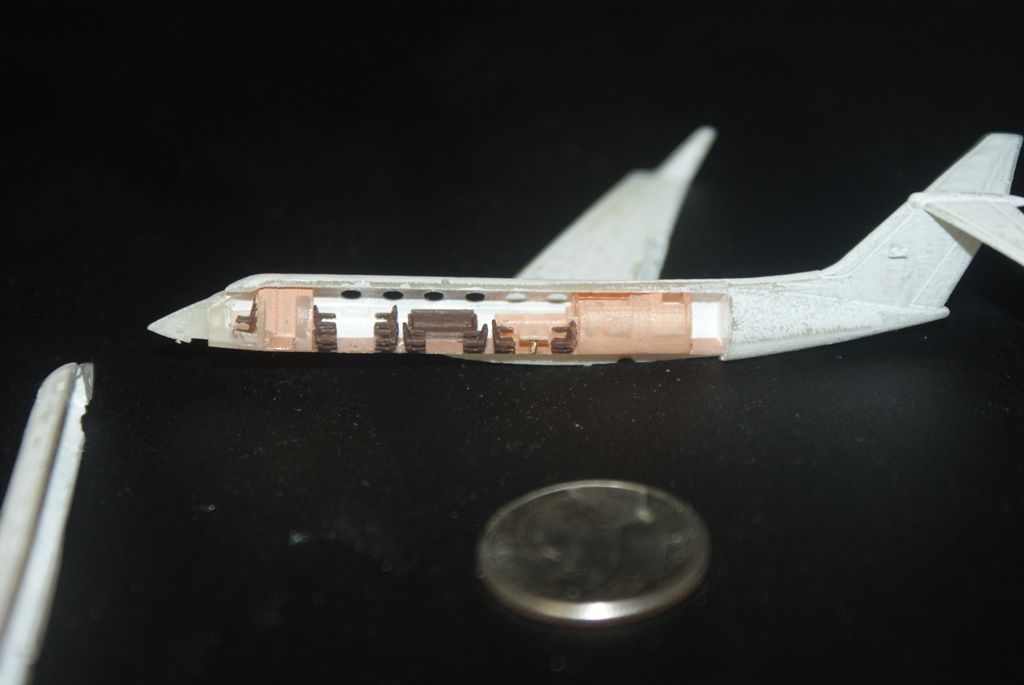

It was a lot of fun and quite a challenge trying to figure out how to do it. The first thing I had to do was give myself better reference in relation to the ground, so I extended lines straight down from the door edge as may be seen in the first image below. I then drew lines, from the bottom of the wheels perpendicular to these lines (not shown), and connected the intersections with a line. I then drew lines from these end points, horizontal out from the centerline of the aircraft. These last two steps created the “C” shape shown in the images, and weren’t necessary, but they helped me visualize the area better. The next thing I did was extend lines from the door edge down at a 45 degree angle, which was a WAG based on the few pictures I have. It turned out to be a pretty good guess. The green extruded circles, seen in the first image were subtracted from the door to create a notch in it, as shown in the second image. I then made the upper support arm (or whatever it’s called), as seen in the third image, followed by the lower arm and hinge{?) as seen in the fourth image.

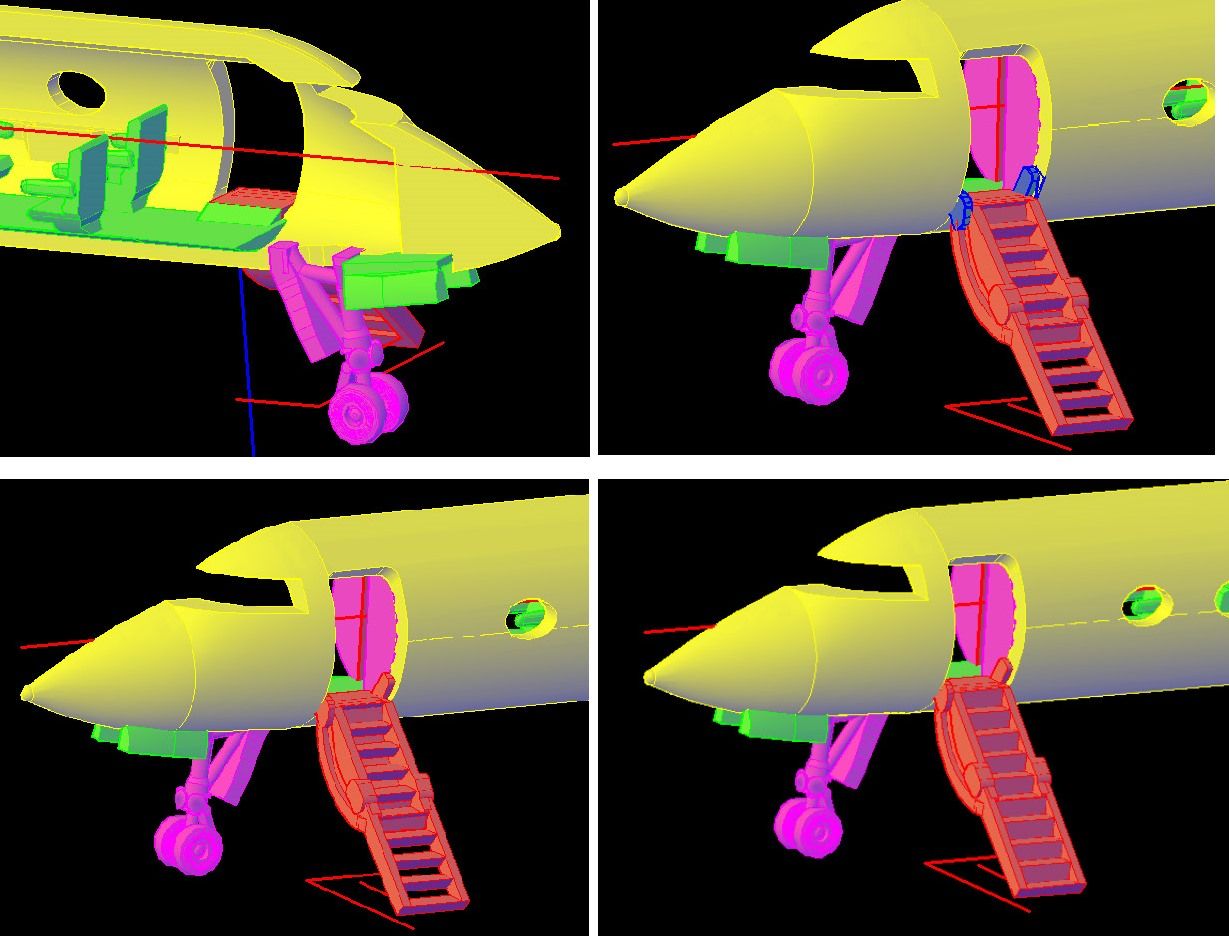

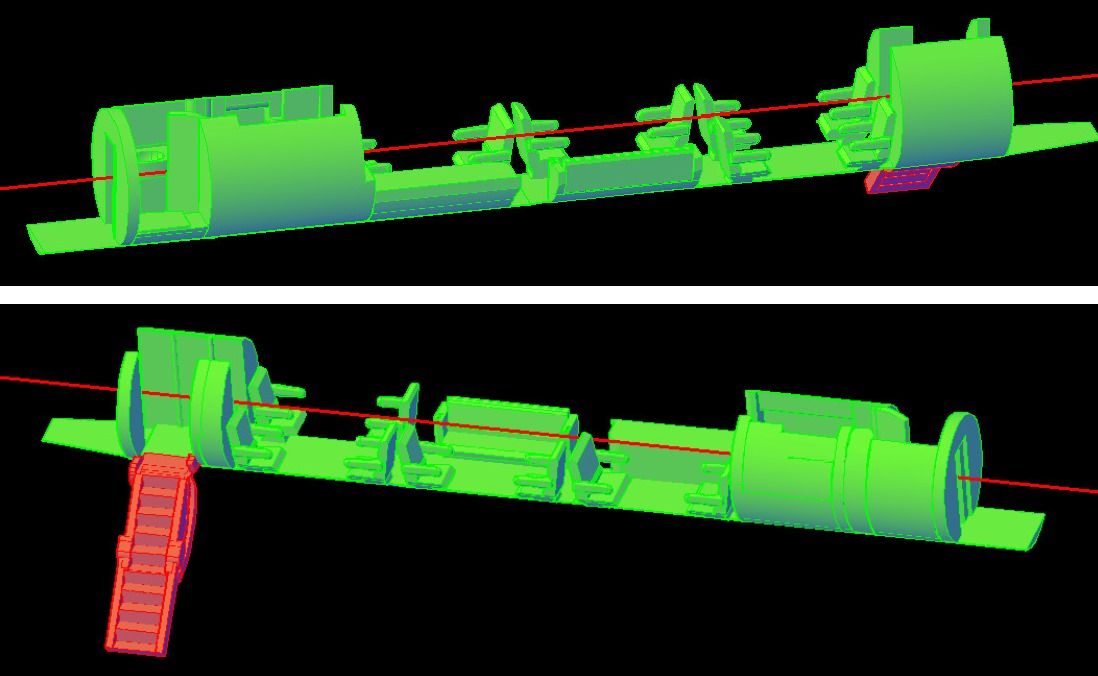

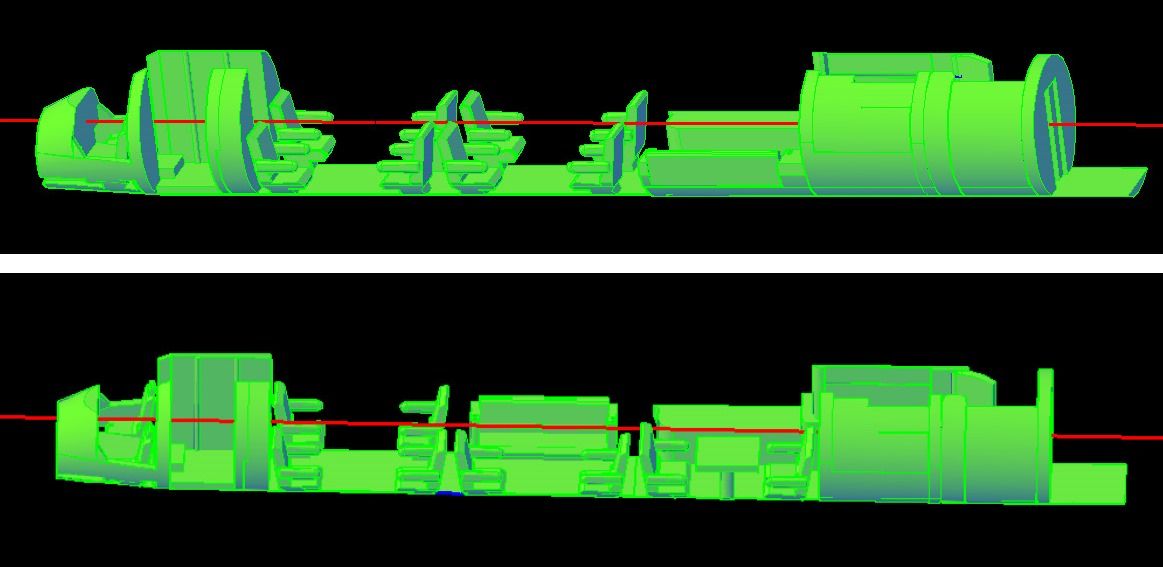

At this point, I mirrored the arms and hinge to the other side of the door (in this case I could have copied them instead) as seen in the first of the next group of images. I then created the lowest ladder rung, by extruding a closed polyline between the arms, as seen in the second image. The Array Command was used to create 10 equally spaced steps as seen I pictures (third image) and everything was joined together with the Union Command (fourth image.

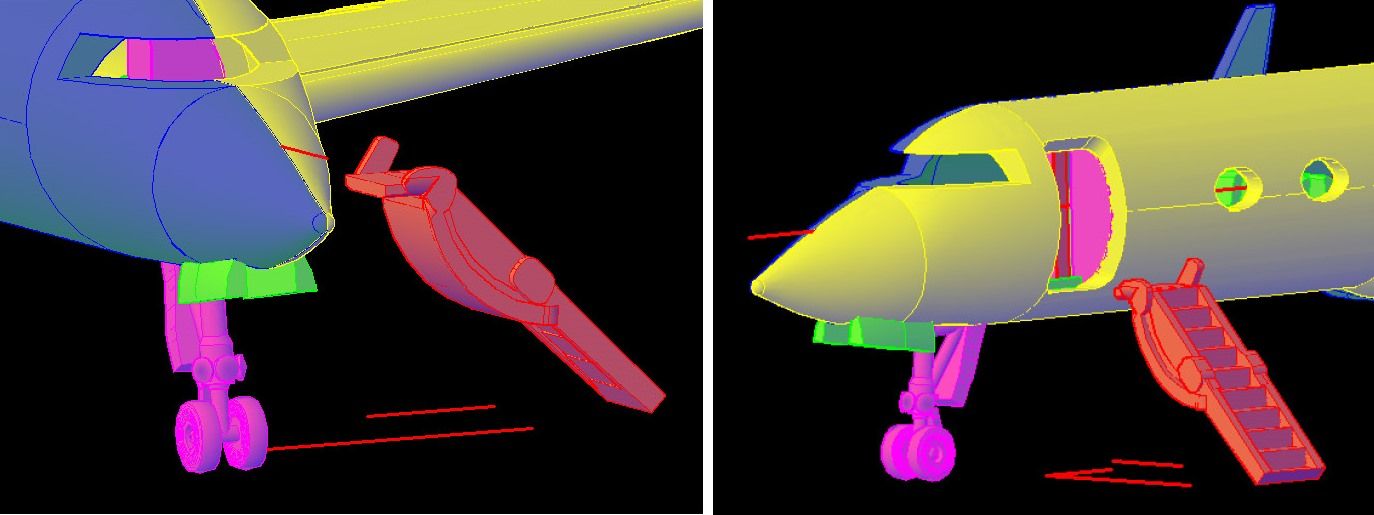

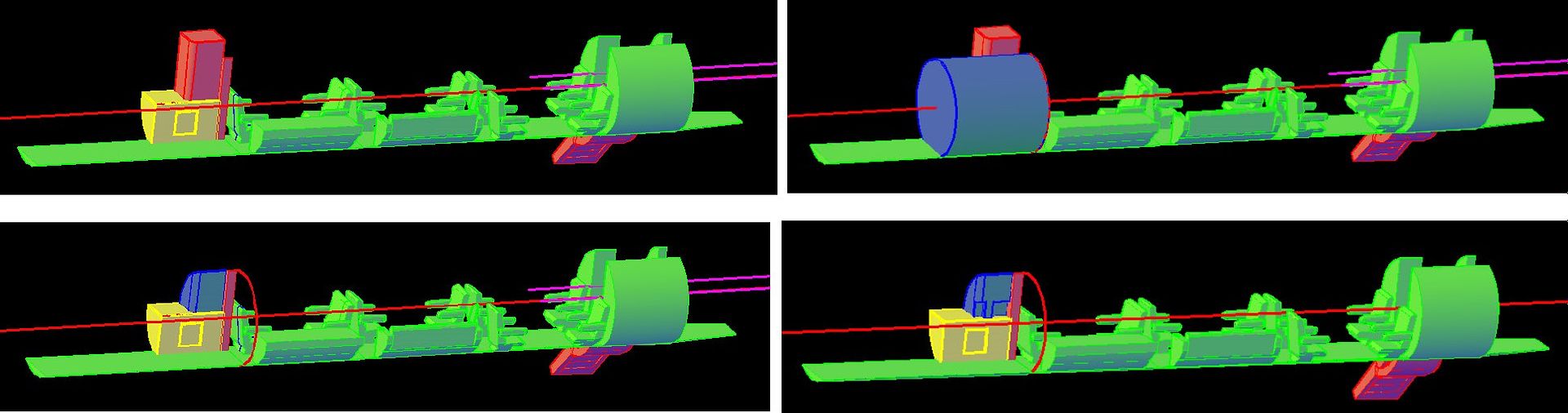

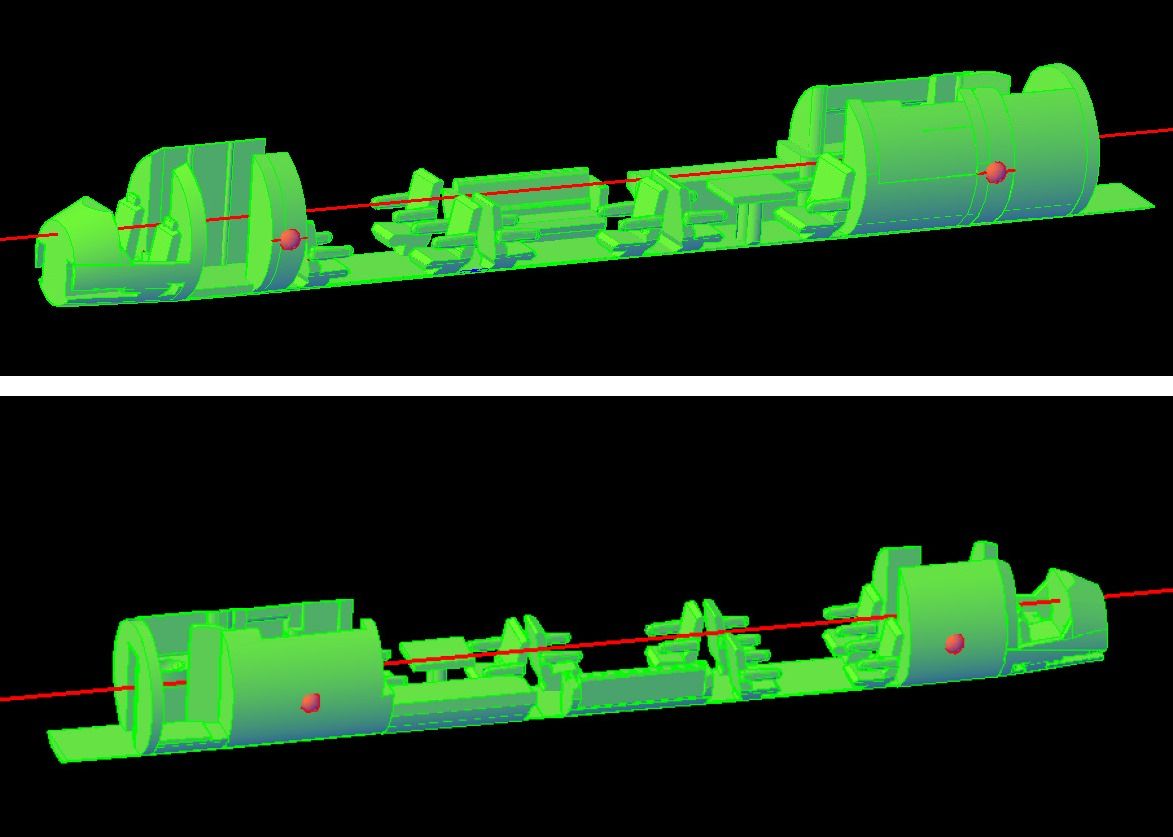

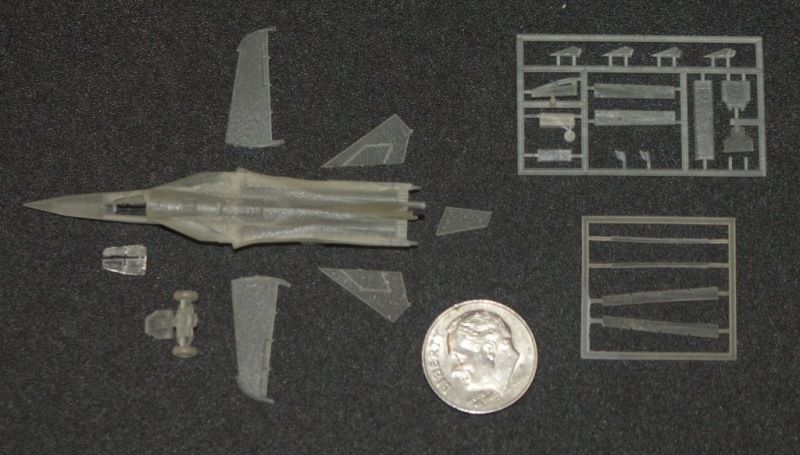

With the ladder created, I next had to figure out how best to attach it to the model. In the first image below you can see that the top of the ladder is slightly above the level of the cabin floor. This was done intentionally so that the open door/ladder assembly could be secured to the model. To match this surface, I created a ramp on the interior part to match the face of the top of the ladder. Next, I added the hinge and housing at the base of the door. Note that the bulkheads (magenta) have also been temporarily added to the interior. In the third image, I have joined the parts together, and in the fourth image I have added the front risers to the steps, noticing that the way I had them was wrong.

More on the door/ladder in the next update.

CHEERS!!!