@Dre…the instruction on the Aires box says you need to thin out the outside/back of the rear wheel bay ( remove the shaded part) but doing this will leave the part wall too thin and will warp anytime the weather goes up …took me a while to figure out how to avoid this …CA(super glue) will require complete drying before you can apply force ,using accelerator or household baking soda will speed the process and welding one side at a time will give you a good fit…the space/gap you see on the picture is just the angle of the camera/lens but on a straight shot the gap are just minimal

OK, thanks! The resin instructions I have don’t mention any shaded part, just a diagram showing ‘this goes there’. I was also unsure if the wheel well walls were to sit flush with the exterior plastic or not, but that pic certainly tells me otherwise.

I was planning on using a 2-part epoxy to set mine (when I get back to it)- surely that will do?

You might feel that you’ve remotely built a second Tomcat by the time I get done asking dumb questions about this one, sorry.

I’m in the same boat as dre. I’m following your build closely as I plan to be starting my trumpy bombcat soon. Got my am parts, including the wolfpack cockpit. And I just ordered 2 sets of corrected intakes. (I have two trumpy tomcats)

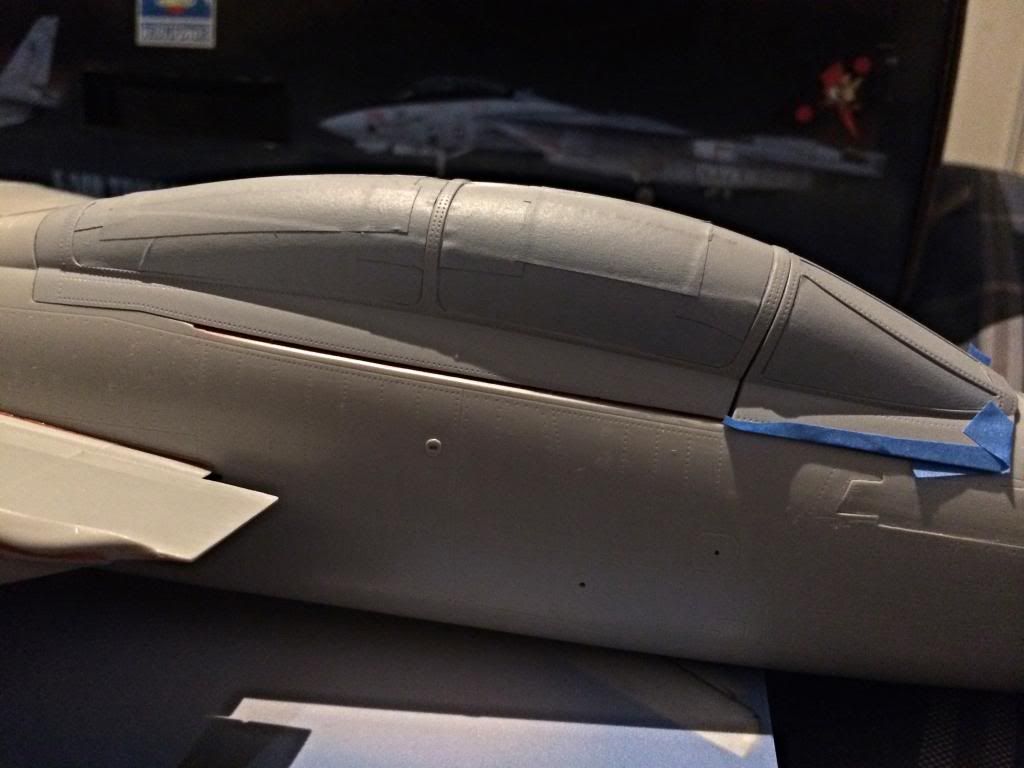

the beast is now taking shape…decided to go with a flat wing so i can move them open/close

PE parts was added on the 20mm vulcan cannon …just need to figure out how to make them open and close

fixing the gap will mean keeping the gun bay closed for good

heads-up for those using the Aires wheel bay …if you open up the wings all the way a section of the wheel bay will come in contact shaving this area extra thin will help

love the trumpeter for making this extra effort instead of correcting what can be seen [:#]

Looking good! I guess that their priorities lie elsewhere…

Amazing!! I’m listening to Kenny Loggins right now!! I can’t wait to build my own. =D

Georgeous work. Looking forward to more updates.

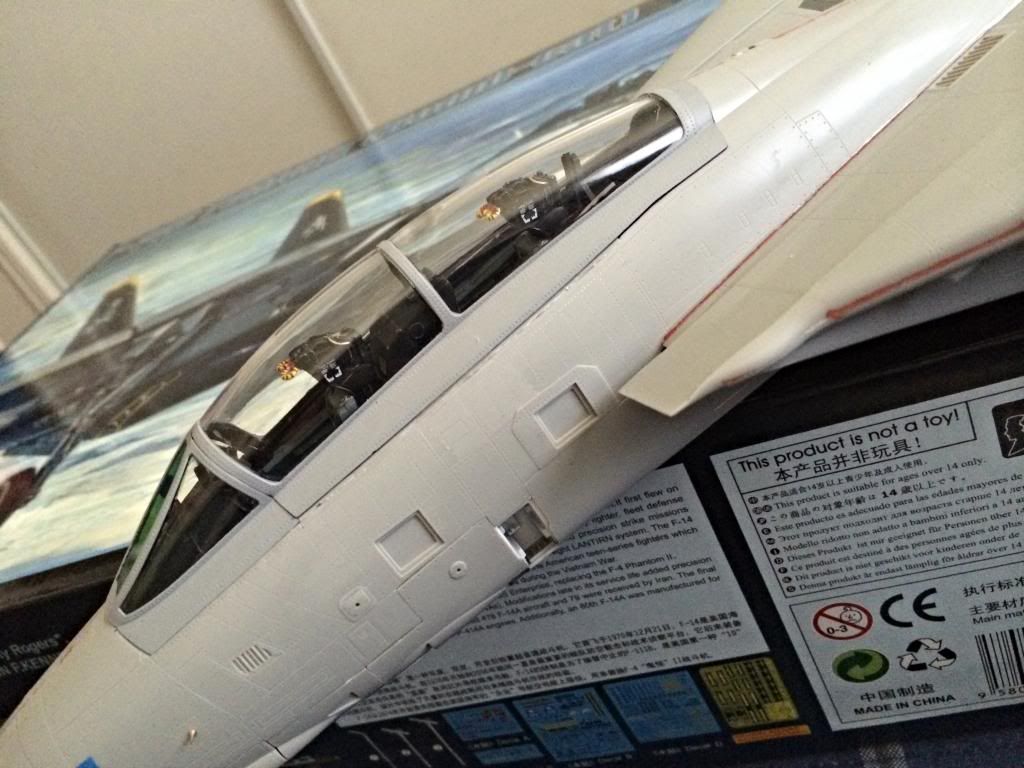

Encountered another bump …was trying to complete and close the cockpit when i dry fitted the canopy this is how it end up [:@]

Encountered another bump …was trying to complete and close the cockpit when i dry fitted the canopy this is how it end up [:@]

What’s causing the mis-fit? I had a similar issue on their 1/32 Su-27 and it took careful gluing and a very strong tape to get it sit properly.

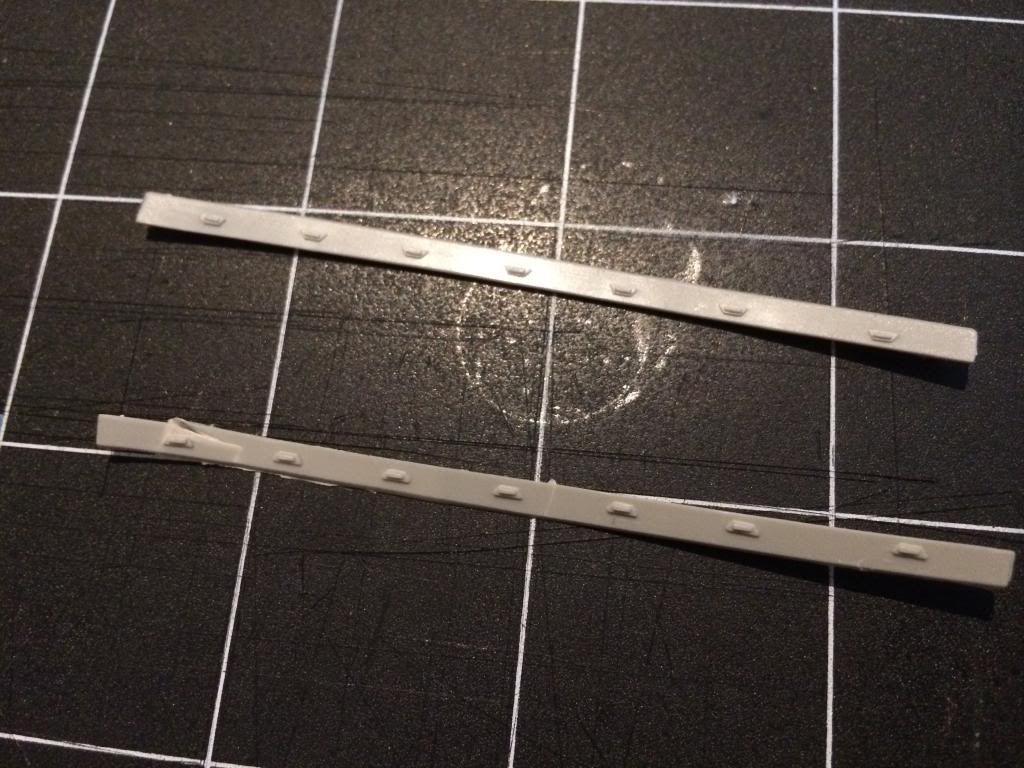

This 2 parts(part# G5,G3) are the one causing problem …had to grind the latch on the canopy and will re-create using styrene

guess the trumpe people did not want the canopy closed…[8-|]

I heard the Trumpeter kits were kind of quirky, guess thats one of the quirks

more update…

Able to shrink the gap on the canopy by shaving the underside of part#G5 and G3…the trumpe bomb rack will be replaced with wolfpack resin …tried to fix the lifeless looking trumpe bomb rack with PE parts…not happy with the result[:'(]

Zactomodel intake are on the spot…very happy with the result

enjoy…

You’re absolutely right about those intakes! They make this shape work. =]

I’m not too into jets, but this is great work. I look forward to the finished product…and those engines are nothing short of spectacular…

Joe

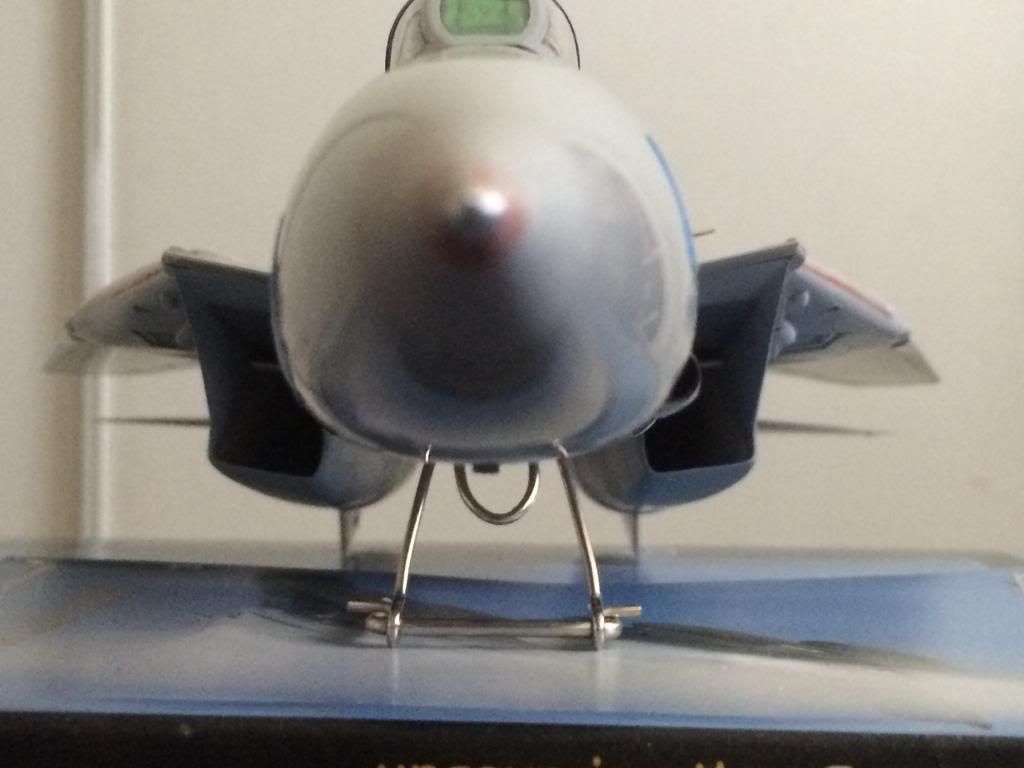

update…worked on the landing struts added some lines/PE to make it acceptable with the Aires wheel bay

dry fit was a success …no fitting issue here

Did some minor re-shaping on the trumpe parts so it can snap in with the aires bay

same with the front struts

enjoy…

Update…

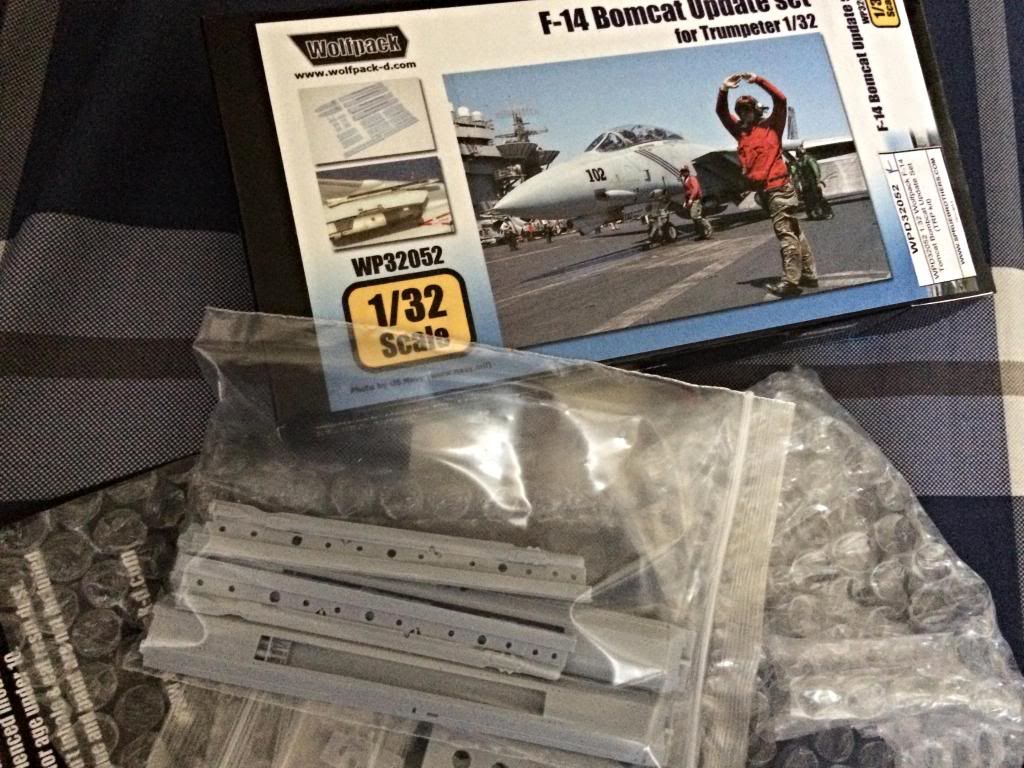

The wolfpack bomb rack showed up, work on the F14 continues …

the beast is starting to look and feel heavy …

enjoy…

Great progress Bimski - I’m really enjoying this WIP thread.

I have the A version in my stash - it’s on the backburner until I feel confident enough to tackle it.

Picking up some great pointers from your build though.

I bet that its quite heavy now, what with all that resin. Great work all around and those landing gear tweaks are very sharp!