A few years ago, I created a custom 1:48 model of the Cletrac Tow Tractor for Brian Bunger, the proprietor of the one of the best hobby shops in the USA (Scale Reproductions, Inc. - Louisville, KY). It was a decent rendition, but not perfect. The scale wasn’t big enough for my 3d printer at the time to reproduce them. Recently, Brian was contacted by a fellow in Minn. asking if someone could build him a 1:32 model. This person is fortunate enough to own a real one. He had seen a post about the one I built for Brian. Brian contacted me and my new client and I got going.

In the ensuing years I upgraded to a new Elegoo Saturn 4 Ultra. Not only is it big enough to handle the larger scale, it’s also much faster, more accurate and can produce ridiculously fine details. Some of you may be following my build thread on the New Jersey Engine Room that is really putting this machine through its paces. (Battleship New Jersey BB62 #3 Engine Room Start-to-Finish Build - #2 by Builder_2010).

This project has come alive again. Brian Bunger (of SRI in Louisville) was contacted by a fellow who owns a real Cletrac and wants me to make a model in 1:32 for him. With the new Saturn 4 Ultra and the success I’ve been having building the Big J Engine Room #3, I changed the drawings to refine some of the coarser details. Here’s the refined drawing and some of the enhanced details. I also changed the drive and idler wheel designs based on pictures sent by the client. There are still some minor differences, but they wouldn’t have print well with them included. In the few years between the first design and this version, my SketchUp skills also improved letting me enhance the project.

Rendered in V-Ray

Screen Print out of SketchUp.

I was thinking about individual track links, but the 1:1 track is a rubber belt with cleats bolted to it. Individual links, therefore, would be untrue. I was able to draw (and will print) tracks with some corect sag in them.

I drew and was rewarded by the printer reproducing the fan and double v-belt.

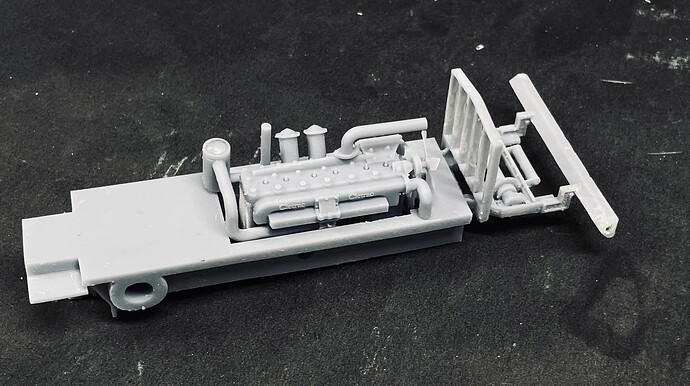

Here’s the print;

I didn’t know it that would work since the fan blades are really thin. Last night I printed the entire frame with the grill guard in place and the driver’s compartment. It’s not cleaned up yet. Next up with be the entire running gear. The gear will fit the frame with integral alignment pins. All of the accessory parts will be printed in the next couple of days.

The refined brush guards as drawn:

And as printed:

Painting the headlight lens will be tricky behind the grill.

The hardest parts about printing some fine details are getting supports that are small enough (and strong enough) to help in forming the part without destroying it in the process, and trimming those supports from the part without cutting the part. That’s why for these tiny things I make a lot more than I need.

I also thinned the air hose rack tips from the 1:48 version.

With the refiinements I’ve made it should go together as a kit pretty nicely. The last iteration was not engineered as well. I will post further developments going forward. Not a lot of parts count, but that’s the 3D printing effect.