Since the wheels will be on the ground, you will only have the weight of the coach on the axle spindles. An alternative might be to finish hollowing out the axles and epoxy in a brass rod. Would also go a long way to filling them and get an axle without the slots the molding process left.

Thanks Dodgy.

I am no expert with molding either but I have dabbled some. The blue-stuff works ok but it tends to trap air bubbles as you press the stuff in place. That has been the biggest drawback, in my experience. It takes some monkeying around.

Other than that it is easy to work with and it does not take much setup to try this, so, I will. Maybe I will get lucky. One other thing I forgot about the video. The guy uses two part epoxy for the cast. I have some of it, a different brand, and from my experience casting with it, it captures good detail, it is light weight, it’s strong, it has low shrinkage, and it sands/drills nicely. I will try that, and not resin.

All.that said, maybe 50/50 this will work for me. Either way, I will report back.

Exactly right. So if I have to go with all metal, I won’t install the wheels until the very end. My biggest concern would be having them installed early on, all the handling putting stress on the undercarriage. That said though, I would prefer to install them earlier than later because I will want to gauge clearances as I work on things. There is my dilemma.

Something to consider. We’ll see how this shakes out. It’s all part of the journey!

Thanks GH!

Using the epoxy was a BIG el FLOPPO. It did not produce the detail I had expected. The epoxy that I used is a different flavor than what I have worked with before, so that might have something to do with it. It doesn’t matter though because I quickly found out that two part epoxy is not a good fit with two piece molds. You basically have to squish the mold together and that can lead to distortions with the cast. The best solution would be a liquid resin.

This presented a dilemma. I can’t use quick setting resin because the resin generates heat, and heat softens blue stuff. It would basically destroy the mold detail. The only other option to consider is a slow setting resin, and I just so happen to have some called Puduo. As a hail marry pass, I tried it. And what do you know-- it worked very well.

I am amazed at the amount of detail that both the Blue Stuff and the Puduo had produced.

At this point I could stop here and move onto making all 4. The downside is that the mold process won’t allow me a more precise finished piece. This cast needs to be trimmed not only along its circumference, but also within it’s spokes. It could be a lot of work. This got me to thinking. I have gone this far-- why not make a better mold using silicone. Yeah, I’ll have to drop about $35 to buy it–but I should end up with a much better end product. If done correctly, there ought to be little flash, and the internal structures should come open like the master is. Or at the least, maybe a thin film of flash that can be easily trimmed. The above will not be easily trimmed. I’d have to grind them open.

I could also purchase a fast setting resin but that is another $35 to $40 bucks. This is why I like to avoid all this fuss with molds and such. In the end I could spend $70 to $80 just to make 4 wheels. That is ridiculous. And to make things worse-- these products have a shelf life, and a short one at that. If I could use them for a future project, that would be a different story. But that is not the case. Once opened the resin goes bad after maybe 3 months, not sure about the silicone, but I hear it is not that long either.

So-- for the sake of a better product and to take a shot at learning a new process–I will buy the silicone. For the resin, I will stick with the Puduo. It seems to work well. The main downside with their product is that I have to wait a good 2 to 3 days before demolding it. That’s ok, I can wait.

A few more points:

-

I plan to attach the hub and rivets so that they become part of the mold/cast. This will reduce some work and gain some consistency. I need to make sure the master is done right then.

-

Remember what I said about the bubbles and Blue Stuff? I think I figured out the problem. As in the video it is recommended that the product be boiled until soft. Here is the problem. Doing that introduces water into the mixture and that creates pockets in the mold. I decided to use a heat gun to soften the material and guess what? I had seen no issues with divots. If anyone tries this – just be careful. The stuff gets gooey and if too hot-- you can burn yourself. Blue stuff is cool stuff, and it has its place for simpler molds.

And that is enough bloviating on my part.

Sounds good mate. I wait with bated breath on your next report, (or was that the tuna I had for lunch).

Man this is CRAZY cool!! Sorry I’ve been missing out on this one brother. Will be glued to the set now though.

I tried casting my own parts and made a BIG mess outta it. So I’m really interested in how it goes for you!

Lol! Your are a hoot sir!

Hey there, Joe. No need to be sorry!

Nice to hear from you sir, and thanks for the nice comment…

Hey Cliff, well, you came to the right place. I am interested in how it goes for me too! [:O] I will document this step by step. It will be the good, the bad, and the ugly.

I have high hopes, and that is usually when things go south on me. [:|]

I ordered the mold material today. I will try Smooth On, Mold Star 30.

https://www.smooth-on.com/product-line/mold-star/

Looking forward to trying this. I have always wanted to make a silicon mold but I never saw the need for all the fuss.

And after spending my wad on mold material, all I have left is a Fist Full of Dollars…

If only I could find my way For a Few Dollars More…

Posting those videos are my tribute to Clint Eastwood. He is releasing another movie at a time in life when most actors will have long disappeared from the movie scene. What an incredible life and legacy. Cheers to you, Clint. [B]

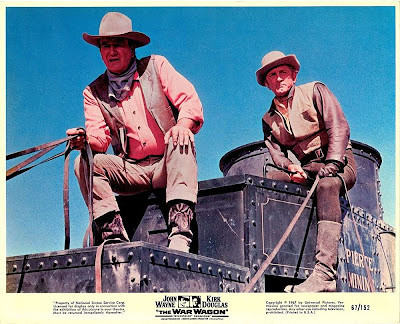

All good, but this might be more of a John Wayne build…

Whose given name by the way was Morrison

Bill

I dunno about Mr. Eastwood, but if you keep making those jokes I’m gonna have to have another frothy!

Hi;

Are you trying to say you might be related?

Amen to that brother!! [Y]

So what you are saying is, my jokes are driving you to drink. Not the first time I heard this. LOL.

Yeah. He is 91 years old and still dedicated to his passion. Anyone that drives their gift to the end like that gets my total respect. What a great example of someone living his life to the full.

I remember seeing his first spaghetti western at a drive-in theatre. Love the music too.

Hell whaddaya waitin’ for…grab two!!