She’s looking really good Toshi.I’m a big fan of Tamiya Extra Thin Cement. The applicator brush that’s part of the cap is nice.much better than the bushy one that comes with Testors liquid cement.With that I have dedicated brush that I use. This kit looks like a complicated beast,but you seem to be taming it nicely…Douglas

To roger_wilcox,

Thank you for your support and words of wisdom. I too have the Testors liquid cement, and yes, the brush is questionable. Hence my purchase today of the Tamiya Extra Thin Cement.

Toshi

Last night, I took Mrs. Toshi out to dinner at Rockne’s, a local Nothern Ohio eatery and pub and we both had a bowl of chicken dumpling soup followed by loaded fries and our main entree of Reuben sandwiches. We then went home to just relax, well Mrs. Toshi did and I went straight into my Corsair build. Yet surprisingly the Corsair build is my way of relaxing.

I was left with the daunting task of glueing both left and right side of the F4U main body, for me personally, this is where my biggest mistakes occur. Too much glue, not enough glue, fueselage not square, interior components not lining up to specifications. This leads to putty and more putty and sanding, and more sanding.

After several YouTube videos on fueselage assembly, I finally went to Hobby Lobby and purchased the Tamiya Thin Cement that seems to be used by every serious pro-modeler. They and forum members were right on the money, this works exactly like the way it is portrayed. One of the guys I love to watch via the Tube is ISM (International Scale Modeler). He does a excellent job on fit and finish although some of it can be very boring, I try to use his technique and equipment and supplies to emulate what he’s assembling.

Inch per inch, I slowly closed the body of the Cosair, found the weak points and placed some blue tape and clamps, to straighten the F4U-1 Corsair. Most items purchased via commercial advertisement don’t always live up to expectations. Tamiya is one company that has me religiously following the Tamiya branded items. I will point out that some of their products are pricy but well worth the cost as it does exactly as advertised.

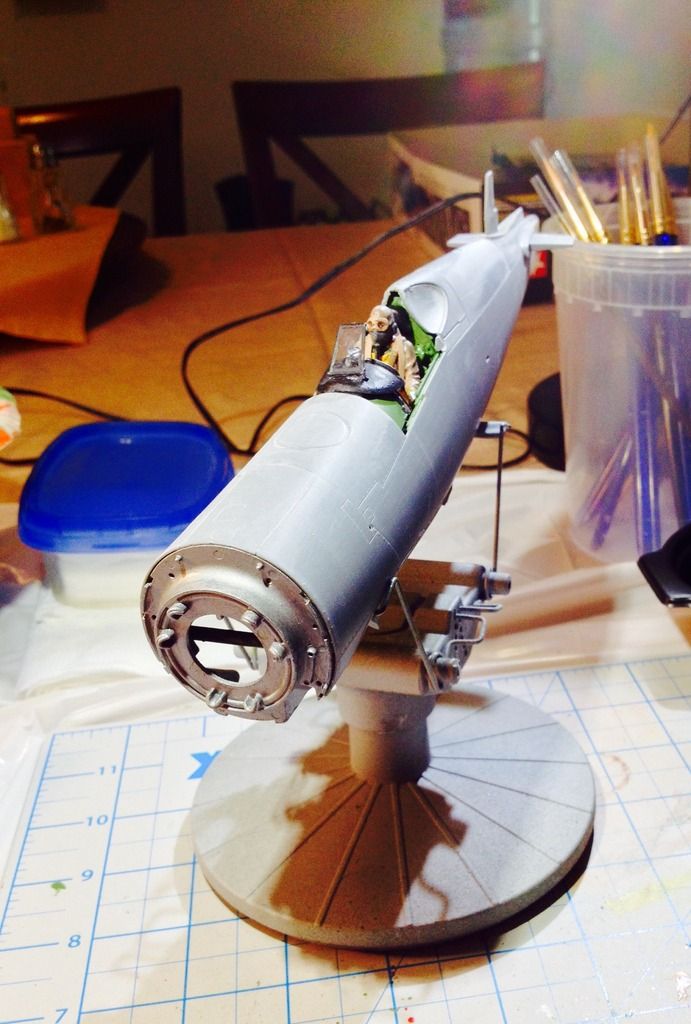

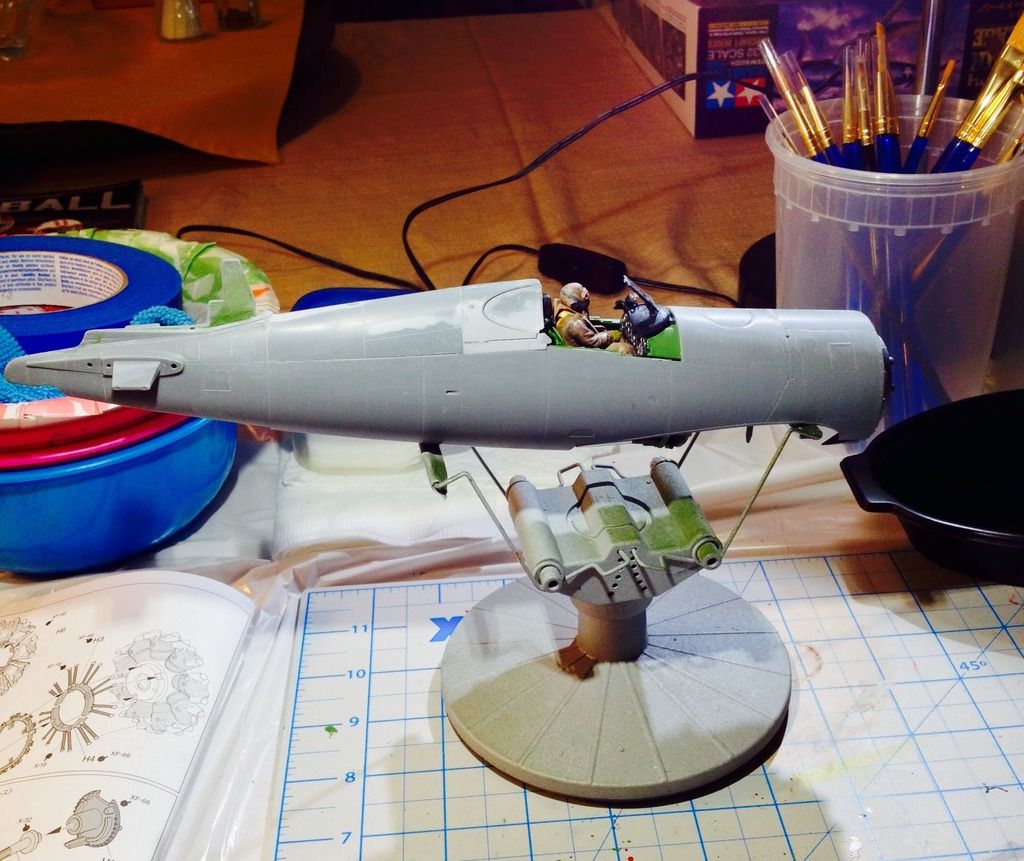

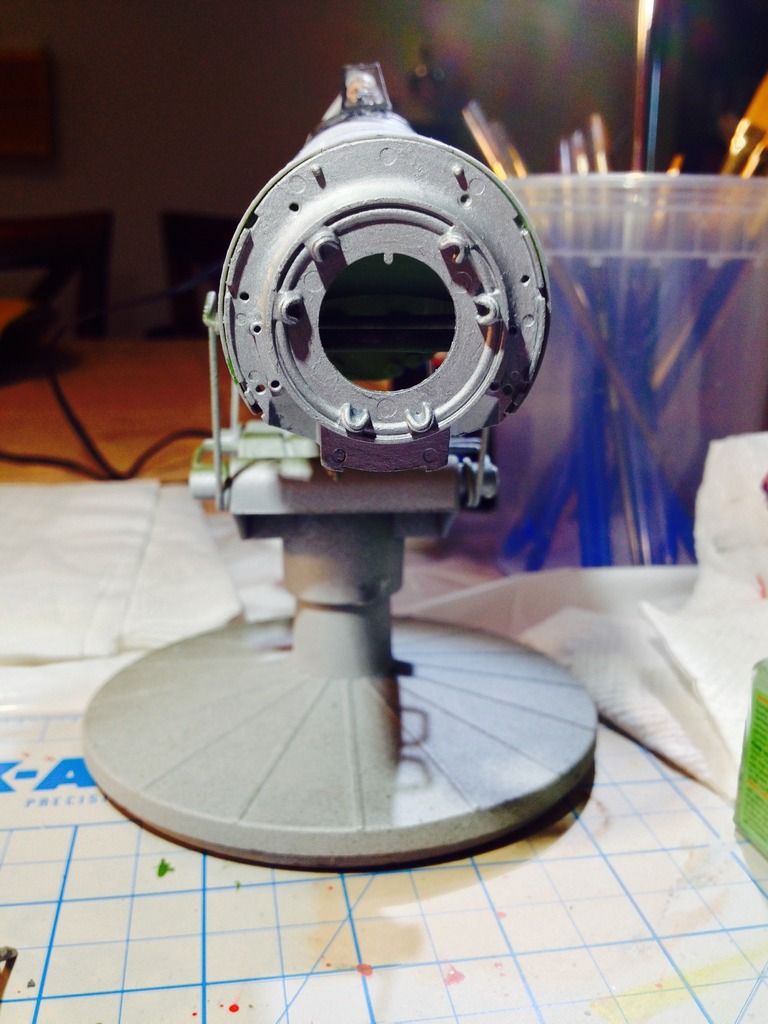

Below are a few photos of the completed fueselage halfs glued together.

Toshi

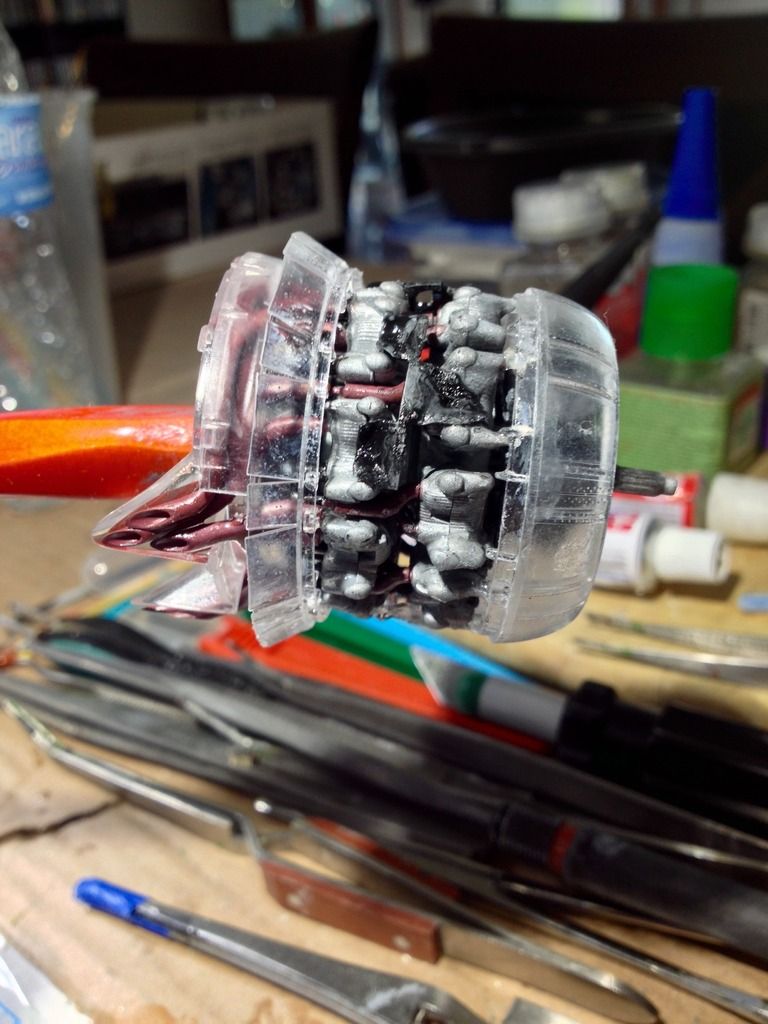

These three parts and the cockpit are the key to a successful assembly of the front end, the tail end with the complicated cage is the last key part in the assembly procedure.

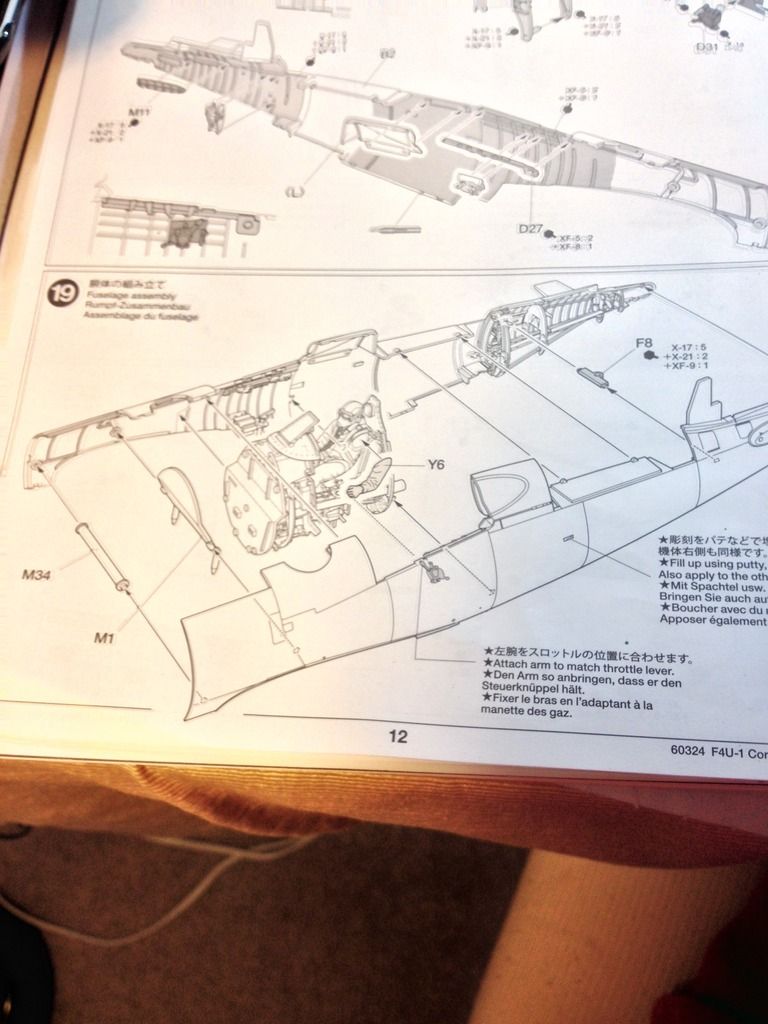

Here is a photo from the actual build guide/sheet.

As I did for the last several weeks, sleep finally overtook my senses and I left the Corsair to dry for the night.

Hey Toshi the cockpit looks great!

I didn’t see anyone mention it but ‘Frog tape’ is also really good for masking- it looks like Tamiya tape but you get a really big fat roll for not much more money.

To Gamera,

I’ve never heard of “Frog Tape”, that’s a new one for me. I’ll google it. Thank you for the heads up and the read and reply.

Toshi

Wow. I’m busy for 5 days, check in and you’re 1/3 done with another one. [:)]

Looking good, Toshi.

Hi, Toshi -

I buy my frog tape at a Sherwin Williams paint store near me, I imagine it may be available at many similar stores. Very good quality and inexpensive. It has it’s uses, but still I slightly favor Scotch Blue Tape for most of my masking. The Tamiya tape works best for me cut into about 1/16" strips, used to mask straight or slightly curved surfaces, it doesn’t curve tightly as well as the Blue. The Blue, cut into those fine strips makes and holds a fairly tight curve.

Another effective tape for masking is Scotch Removable Tape, good for masking the entire area, easy to cut and removes without lifting paint, BUT, it does sometimes tend to leave a bit of residue behind if left on very long. That is quite easy to remove with just a little finger rub. That tape though, will not bend to make a curve.

The Corsair is coming along quite well, you’re doing a good job of aligning and clamping as you proceed with your gluing. She’ll be a beaut when finished.

Patrick

To Greg,

With the kids living on their own and Mrs. Toshi at work, I’m left with household chores, three cats, and a teddy bear hamster named Albert. No, they are not mines, two cats and Albert the hamster belongs to my daughter. Now I’m stuck with litter and hay! LOL.

As for my time, I’ll do some building of the Corsair, take a break, watch a You Tube video on model kit assembly, and go right back to my beloved Corsair. That’s the make up on most days, the rest are dedicated to doctors appointments and Mrs. Toshi on her days off.

I had to stop a few times with this F4U-1 kit, there’s questionable and confusing data. Of course this is not Tamiyas fault but my own. I’m still sanding the fueselage, then comes the engine and wings. It’s like forty five to fifty pages just on the wings (The folded wings are also part of the included description) it’s a huge task to tackle but it’s part of the most gratifying and exciting parts of this build, especially when things start to take shape into a Corsair. Thank you for the read and reply!

Toshi

To Patrick206,

Thank you for the masking and what type of tape information you’ve shared with me as well as other forum members. Masking might be a joke to the simple observer but, for modelers this issue can become a make or brake scenario.

Thank you for stopping by and sharing that vital information.

Toshi

Update for 6/5/15,

This is just the pre-prep of the fueselage prior to the wings and tail section, once inserted, I’ll double check maybe even triple check any discrepancies before I airbrush the Tamiya Gray Surface Primer. Remember, measure three times, cut once! In this case check and sand three times, spray once! LOL

This is just the pre-prep of the fueselage prior to the wings and tail section, once inserted, I’ll double check maybe even triple check any discrepancies before I airbrush the Tamiya Gray Surface Primer. Remember, measure three times, cut once! In this case check and sand three times, spray once! LOL

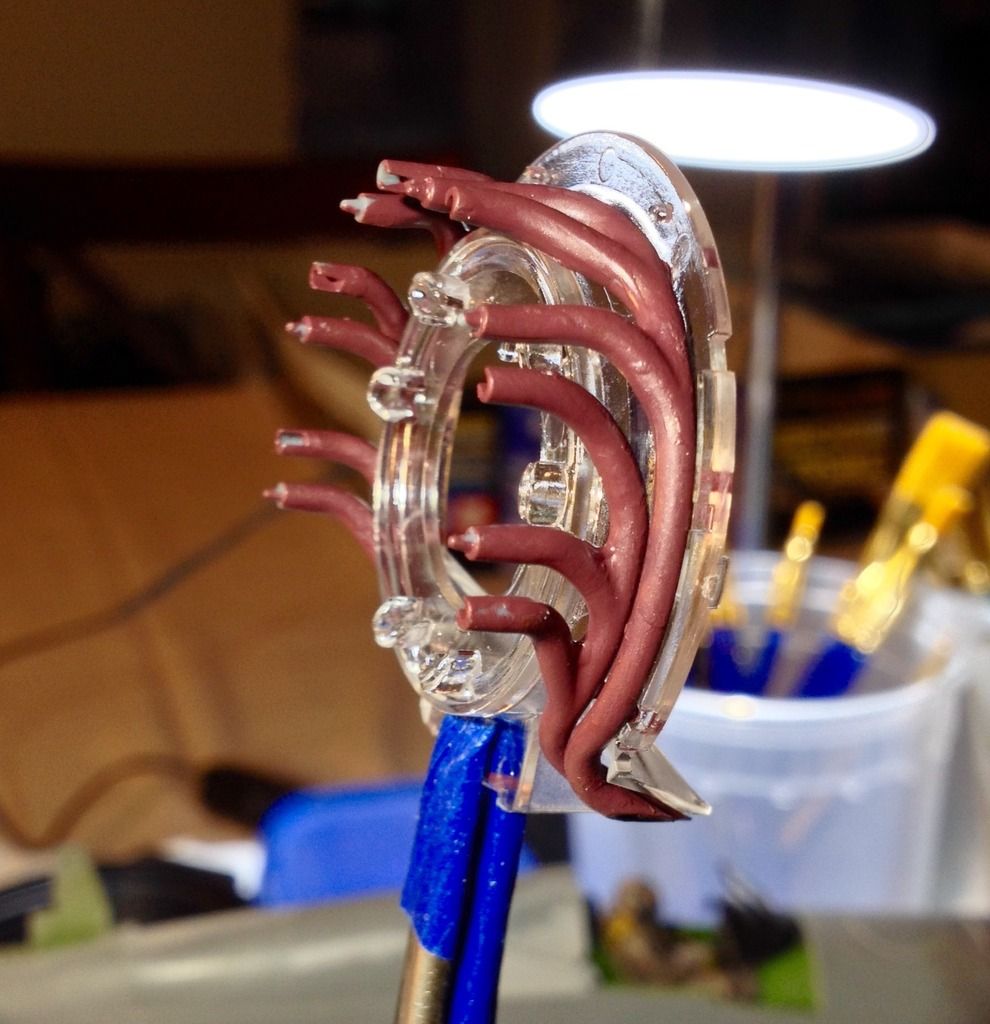

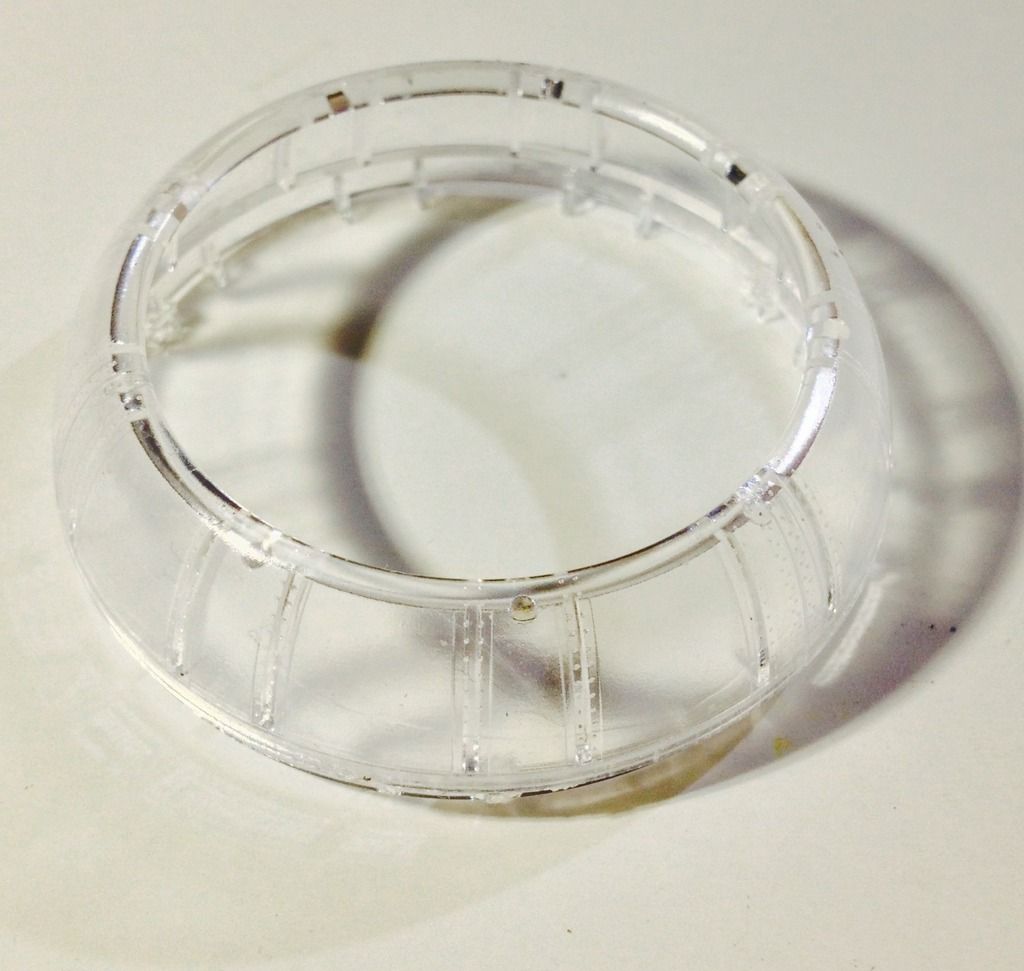

I’m going to go with the clear cowling. I’m concerned with finger prints and even a speck of paint hence, while the engine will be constructed away from my work station. Actually the dinning table! LOL .

This is not the Tamiya formula, although the base is. The rest is of what I have in inventory and looking at other builds on the Internet.

I did not know what to use as far as the glue is concerned. I thought of CA, but with clear parts, it will look like San Fransico bay. LOL. Then I thought of Testors Clear Parts Cement. The rest of the engine will be secured on this base constructed with the exhaust system. I’m weary that the Testors Clear Cement can hold that weight. I finally went with the Tamiya Extra Thin Cement. I’m confident this will hold together. Thank you in advance for your time and support forum members!

Toshi

Toshi -

I was able to use the Testors Clear Parts Cement on my 1/32 clear P-51D (Monogram Phantom Mustang). You’re correct that it’s not as strong as other glues, but it worked for 90 percent of that build.

In this situation, I would use the Tamiya cement on the back plate mounting, and then use the clear parts cement to hold the cowling itself to the plate with the exhaust pipes. I haven’t built the 1/32 Tamiya Corsair yet, but if it’s engineered anything like the F4U-1D in 1/48 that I put the cowling on tonight, any crazing from the Tamiya cement will be hidden, and the rear piece is what does the heavy lifting. You should be fine with the Testors stuff (or Micro Kristal Klear) for the cowling itself.

Also, not sure if anyone else replied, but your interior color is fine. I haven’t seen the pinkish color you mentioned in any of my references, and while it may very well have been put on some, somewhere and be correct for some builds, your green zinc chromate is also correct.

-BD-

Oh, I didn’t think that the Testors Clear Cement was that good. I mean it’s a great product and I’ve actually made windows with it on my Mariner build but, it’s nice to know. That’s a good tip, I think I’ll use your technique.

Recently, there was a Corsair found in one of the Great Lakes. It was in prestine condition. When the Corsair was brought up, it had that god awful pink salmon color as the interior was painted as such. Well, I guess Tamiya wanted to go in that direction, Tamiya can paint the interior with purple dots, I’ll stick with the good old green zinc chromate.

What’s funny is that these 1/32 kits comes with a book on the history and stats on the aircraft to be built. Then in the back of the book, it shows live actual photos of the aircraft your about to build. You are correct in that I have yet to see this pink corsair except for one build that I found on the Internet and it definitely looks like a “Malibu Barbie” Corsair. LOL!

I’d love to see your mustang and Corsair build! Thanks for the tips and the read and reply.

Toshi

Toshi,

Looking good. The Testor’s clear glue is basically watered down Elmer’s glue, so strength is somewhat limited. I don’t have any experience using Tamiya Thin on clear parts, maybe try gluing 2 pieces of clear sprue together and see what happens?

Groot

To RobGroot4,

Thank you for taking the time out and sharing your recommendation as well as the read and reply.

Thank you forum members for stopping by. Next phase are the wings which seems to be complicated and confusing at best. That’s just my humble opinion.

Rob and Toshi - The Tamiya thin, or any other styrene plastic cement will work well on clear parts, but you must be very careful when applying it. It has high “capillary action,” which means it wicks into the small places very quickly. It’s quite prone to travel to spots outside the specific where you want it to go, if applied a bit too heavily.

When I do use it, I make certain that the piece is precisely placed, then using a VERY TINY pointed brush I dip it into the cement jar, touch the brush against the inside of the jar above the cement level, to remove the excess cement back into the jar. The brush hairs will then have just enough cement to transfer to the space between the model and the clear part. It is enough to attach it at that spot, but not so much as to spread to a larger area outside the space and ruin the clear bit by “getting outside the line.”

Once that spot has a few seconds to set and somewhat firm up, I move to another spot away from that one, like maybe the opposite side. That method is similar to what welders do, called "spot welding. As you proceed around the clear bit, eventually you get it all covered.

For my own method I prefer to use white glue, no damage to the clear part if placed incorrectly, easily removable and cleaned up with water for another attempt. If the model will only be displayed and not handled or played with, the white glue is plenty strong enough. If only displayed, I can’t see a reason for a strong glue that makes it a permanent installation, that can actually ruin a part if mis-applied. Just saying.

Patrick