Tony, it was a full day’s work no question there! [;)] Thanks for the comments.

Will, thanks as well. It’s going to be a combination of opening up hatches as well as partial cut-away on some sections like the turret and engine deck.

Tony, it was a full day’s work no question there! [;)] Thanks for the comments.

Will, thanks as well. It’s going to be a combination of opening up hatches as well as partial cut-away on some sections like the turret and engine deck.

Great work as usual! Love that engine, and those PE ammo holders.[tup][tup]

Nate

A Shakspearian discussion leading up to primer…dammm…was dinner discussion as good!!

Oh well…nice progress, Franklin is looking good!

Hummm…I have to talk to the Princeton physics dept. to find out if the difference in time zone at you house causes 30 hour days…all this work and dinner with the wife too…

Rounds Complete!!

Thanks Nate!

Mike, all I can say is that I’ve been extremely motivated on this project. I’m thoroughly enjoying it and that always helps! [:D] Franklin is starting to get stitched together today so hopefully he’ll be even happier to have some integrity at long last! [;)]

WHOA! I have been in California for only TEN DAYS for a conference and you are almost halfway DONE with your #100 by the time I returned. So much stuff for the interior… it would be a shame to hide them! Maybe it is a dumb question… instead of slicing an opening as suggested, just don’t glue the top to the bottom part of chasis so you can lift it up for anybody to see the whole thing? I will be following your build REAL CLOSELY from now on…

Egads!! I better get a move on - you are catchin’ up to me!!!

Looks great, Bill. I am in love with this kit and seeing your interior has made me even more determined to build a second one with all the extra stuff!

Bill the motor and comp. looks great. the added wiring tops it off and adds more life to it. I’ll be looking for this kit next weekend at AMPS, but of course it’ll be built as a wreck, something I’ve planned for over 8 years now. Thanks for the motivation and inspiration.

One thing I did notice on the motor, top view of the motor comp… On the left side is a ribbed part, can’t remember what it is right now, but it looks like you may have missed a mold line, could of course just be my bad eyes. Besides that it’s one great looking motor.

I try popping in every couple of days to check things out and must say this build is going just as quick as your others. Not gripping mind you, I always enjoy your very thorough build blogs. OK I’m kinda jealous.

Rob

Boyd, the weekend has come and gone so this one will sit until the next weekend before more work gets done it. That gives you 5 days to keep ahead of me! Thanks for the comments as always.

Andy, I thought of that but the problem that I run into is that the 38t really needs that roof in place due to the way Tristar designed the kit. Since the hull is slab sided, the roof is what ties it all together so it will sit square. If it’s not glued down, the hull sides bow out slightly at the top. I’ve found what I think will satisfy both requirements…allowing more of the interior to be viewed and still providing enough structural integrity to hold everything together. We’ll see how it goes!

Thanks Rob for the comments as always! I can only imagine what a wreck of this vehicle with the interior provided would look like in your capable hands. You know you want to do it, so go for it! [(-D] The ribbed part on the left side does indeed have a slide mold seam remnant that unfortunately is a side effect of the way Tristar decided to mold this part…they used multiple small “fingers” on the sprue connector so it’s virtually impossible to clean it up properly without leaving a trace behind…the camera never lies and picks it up even though with the naked eye I managed to hide it…almost! [;)]

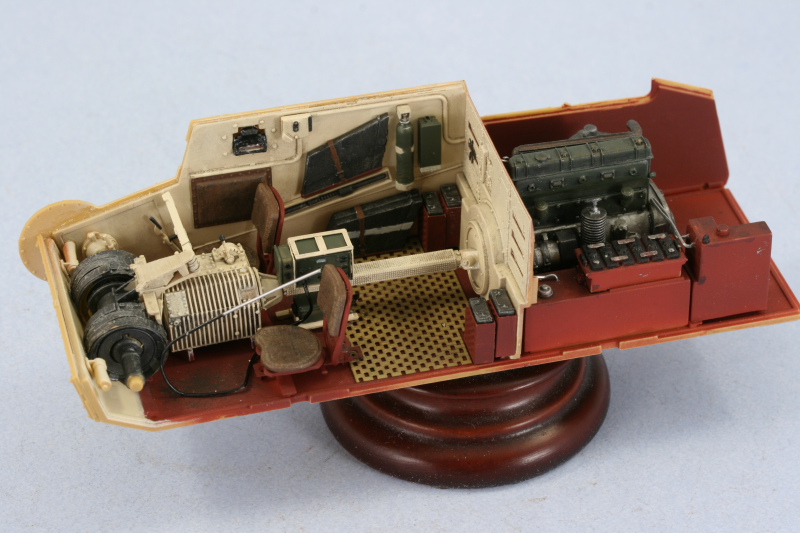

Building on yesterday’s foundational paint work, today was all about painting and installing the various details. I spent virtually the whole day painting and detailing items and it was only as I got to the end of the session that things finally started to get installed.

The first set of details to get installed were on the driver’s side. I added the crash pad, the signal staff, main gun ammo can, and fire extinguisher after hand painting them prior to installation. The Interior Set neglected to provide a first aid kit that is supposed to be next to the FE, so I scrounged around in my spare PE fret bin until I found a box shape of suitable size/dimensions to use. I used the old artist trick of “trompe leoil” by painting in the “rack” that it’s supposed to be sitting in on the base so it looks like it has a holder. I applied a wash of Raw Umber to weather the elfenbein and then dry brushed some of the enamel Panzer Interior Buff over that to blend it back in and give it a slightly grungy look.

The radio operator’s side got a similar treatment and the two ammunition holders were installed. Getting them into the right position required a careful check of my interior reference photos in PT-13 since the Tristar Interior Set instructions are vague at best as to their exact placement. Since they have to clear the MG ammo bins attached to the firewall and the radio operator’s seat, the tolerances are very tight with no room for error. To insure I got them in the right position, I used the masking tape trick again to hold the hull side to the floor with the firewall dry fit in position and then carefully glued the racks in place with CA gel. The white stripe on some of the ammo cans is something that shows up in the PT 13 interior photos, my guess is that it distinguishes between HE and AP rounds but I can’t be sure. I added the stripe using masking tape and careful application of Light Gray by brush.

Next up was the transmission/brake housing/drive shaft. Even though the brake housing won’t be seen, I still painted it up just to be sure that there wouldn’t be any bare plastic viewable. The transmission was given a wash of Raw Umber and then dry brushed just like the hull sides. The Interior Set provides two different radio sets but since this is a normal vehicle and not a command tank, I only used part H48 for the receiver that a standard tank would be equipped with. PT 13 indicates in the text that the receiver was mounted to the drive shaft so it was positioned that way deliberately. The Tristar Interior Set instructions don’t provide any advice/help at all on where the radio is supposed to go since it’s a generic set meant for any of Tristar’s 38(t) vehicles including the command variants. I also wired it up with some 1mm diameter solder that will connect up to the antenna pot on the hull front plate once that’s installed.

I also painted and installed the seat cushions for both crew positions. The driver’s cushions had to be adjusted slightly to clear both the hull side and the transmission while the radio operator’s went on just fine with no issues. The MG bins were added to the firewall and then the flooring for the area below the turret added to get it aligned properly. The transformer for the radio receiver was added, the rack for which I cut down since it was designed to hold transformers for both a transmitter and receiver. It too was wired up so that it could be connected to the receiver once it was installed. The double ammo bins for the driver’s side were detailed and installed with the outer can receiving a white stripe as well. I also weathered the exposed floor areas with dry brushed Steel and Burnt Umber but I don’t think very much of it will be visible in the end…but at least I know it’s there!

The superstructure front plate also received some attention. It received the same wash and dry brush treatment as the rest of the interior and the driver’s periscope was detailed with Flat Black and the green-red-blue signal lights added using regular Testors enamel Beret Green, Flat Red, and Sea Blue. The MG will get added later once the plate is installed to avoid the possibility of damaging it.

With all that taken care of, Franklin needed to start getting assembly…so the driver’s side was added first to the floor using regular glue and finger pressure to get a good join.

Same thing was repeated for the radio operator’s side.

The final act for the day was to add the glacis plate and the rear hull plate to insure that the hull sides were lining up properly. The glacis plate required the use of some rubber bands to get it to sit down flush at the front due to the fact that it needed to align in three different directions to sit at the right angle. After about 15 minutes the bands came off and the hull was together.

Next up will be working on the turret details and then it will be time to do some cutting and fitting of the remaining external details.

WOW!! That’s looking awesome- you’re really going to town on this one Bill- I think the weathering in front of the seats was worth it, it looks great and adds to the lived in look, hey- we all know it’s there too!! haha

Dang that’s some mighty fine work!

Wow, Bill. Just, Wow.

Chris, sometimes it works out that way even though I try to avoid unnecessary work wherever possible. Appreciate the comments!

John, Marcus, thanks for the kind words as well. [;)]

Damn Bill, that’s one sharp looking interior and build, well worth the #100 slot. As far as that engine part goes, I would have gone nuts trying to clean it up.

What ref. books do you use when building your 38t’s, I know I read it somewhere, hope you don’t mind me asking. My interest in this tank is growing and may just build one in the very near future.

Keep up the great work Bill.

Rob

Thanks as always Rob and no problem at all supplying you with information…especially since I know what you’ll do with it! [:D] As for the engine part, I actually had to stop myself from doing any more work on it as it would’ve done more harm than good in the long run. Very fine detail in the ribbing but the limitations of how Tristar molded it were very evident.

In terms of references on the 38(t)s, by far the best one to get without going bankrupt is Panzer Tracts 13 by Jentz and Doyle. I’m also using the Nuts & Bolts #18 on the Marder III H since it’s got beautiful multiple shots of the engine and Spielberger’s Pz 35(t) and 38(t) and Variants (which is a bit misleading in the title since it’s really all about the Czech vehicle manufacturing and not just the 35/38t tanks and chassis). The Spielberger is a hefty tome with a price-tag to match and is more a text reference than a photo reference and has some of the same drawings as in PT 13 but larger. HTH!

BEEEE-YOU-TEEE-FULL!!!

I also find it pleasing.

Thanks Boyd and ps1!

I played around with the lighting a bit and wanted to show off some more of the detail, especially the straps on the ammo cans. Those required some careful work under the magnifier and are tough to see in the previous shots. Keep in mind that there are 15 cans in all including the ones in the turret. I also neglected to mention that I had added the small foot step for the commander using a leftover part from an Eduard PE fret. Getting that in the right position was a challenge as it had to have sufficent clearance that the ammo cans could be removed but still be low enough on the hull for the commander to actually put his foot on.

Just as a trial run, I also dry fit the superstructure front plate, the hull roof with the turret bottom in place, and the rear engine deck to see how much would be visible without any modifications being done. Since the 38(t) doesn’t have a turret basket or any other means to support the turret aside from resting inside the ring, I’m going to retain that portion of the roof but cut out everything else, leaving only the perimeter of the rivet lines plus the turret ring support. I think this will, when combined with cutting out the turret sides, provide quite a bit of visibility down into the interior while still allowing the vehicle to be displayed intact vs. having the turret separate for example.

Bill, all of your detail work looks great. Are you leaving the top to the fighting compartment loose so all of that detail can be viewed? She’s coming along really well.

Freakin awsome im lovin this build , i take my hat of to you[tup]