Awesome work my man, very impressive.

Thank you. It’s been testing my patience as no other model has in my 50 plus years of model building.

yes very good work. Stay with it…I’m sure a project like this will test you like no other but it will pay dividends in the end! I’m both envious and at the same time glad it’s not my project!

That’s a see saw ride that I’ve been on for the last 5 years. An ‘in your face’ love/hate relationship. I’ve even entertained the thought of selling it as is yet I believe I would soon enough regret that decision. So on I stumble and thank you.

The window portals where simply flat, featureless spots on the CM. I’m drilling them out and will create window frames along with RCS nozzles around the bottom of the capsule.

One window framed, the other awaits it’s frame. These are simply cut out of hollow styrene tubing of the appropriate diameter.

Nozzles installed.

Any model rocket to be flown with a tower of some sorts commonly recieves damage in the lattice area. So I’ve tried to address this issue using magnets to hold the LES on. The problem is I have no way of knowing how this system will work until it’s flown. Two things need to be understood: will the magnets be strong enough to stay on during the flight phase and will they be weak enough to give first on a hard landing. All empirical.

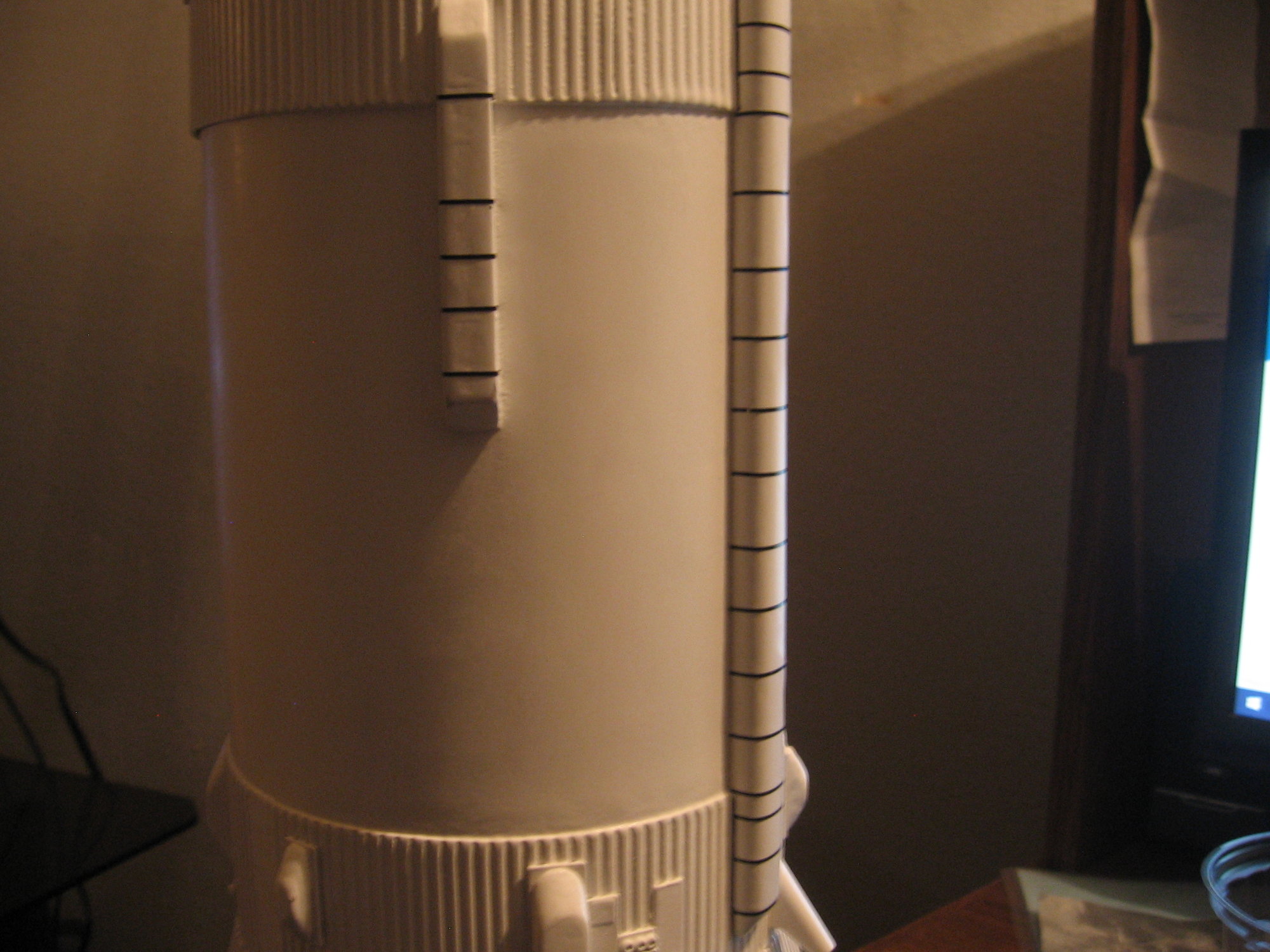

I have recently applied 2 coats of gloss white to the third stage and aft interstage. Gloss will take waterslide decals better, then a final coat of flat clear will be applied. Nothing worth posting as far as pictures are concerned at this point. Once I start taping and masking this section off for the gloss black will I post anything further.

Hold on here. I am confused. Is this model going to fly?

Yes. Computer estimates about 1600 ft. The lower section will recover on an 8 ft. chute while the upper section recovers on a 5 ft. chute.

I forgot how to post photos.

That isn’t working either.

I give up.

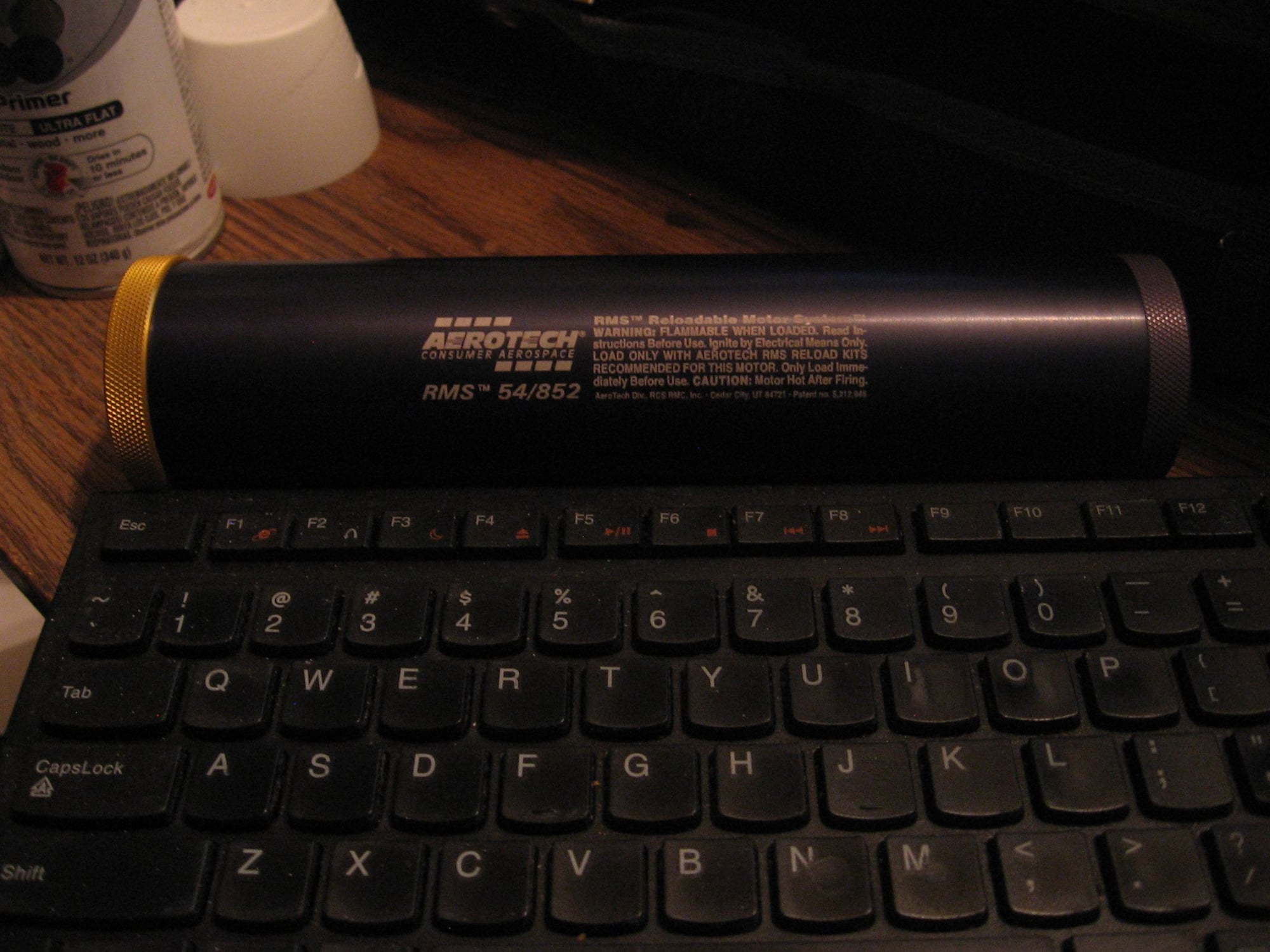

This is the engine casing.

When I was a kid in the 1950’s I had a rocket that would fly. It was made of rock hard translucent red plastic. It was filled part way with water and clamped onto a hand pump. Air would be pumped into the plastic rocket. When the pump’s clamp was released the plastic rocket would shoot up at a high rate of speed. I wonder how many kids lost an eye or a bunch of teeth when the rocket hit them in the face.

I am sure that your rocket will be much safer.

I used to fly those things as well. Yup, red and white plastic. It never even occured to me that a kid could truly hurt themselves with one of those. Mine usually landed out in the asphalt street and cracked. So much for disposable income. Where it concerns larger, more powerful solid fuel rockets, the National Association Of Rocketry has guidlines, launches run by qualified members and safety above all else in mind. FAA clearance when neccessary, certification flights for the more powerful engines and open to the public displays and launches.

For this rocket, I need to be a certification level 2 to buy the reload for my casing. Once certified and given a certification number, I can purchase my reloads from any manufacturer with proof of my cert. by giving them my cert. number. This system keeps the undesirable elements from obtaining these motors and using them in a wreckless manner.

I had been over zealous in sanding and removed a substantial amount of the pin striping tape. Now with the tape reapplied, I will be able to shoot gloss white over this.

I’ve decided to can the first version of the SM and replace it with a 3D printed part from Shapeways.